Method for synthesizing nano dispersible CMC-acrylic acid macromolecule absorbent resin

A polymer water-absorbing and synthetic method technology, applied in the field of polymer water-absorbing resin synthesis, can solve the problems of difficult heat dissipation, high viscosity of the polymerization system, and the molecular chains of the polymer water-absorbing resin are dispersed at a nanometer level. The production safety factor is high, the process flow is simple, and the effect of controlling the synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

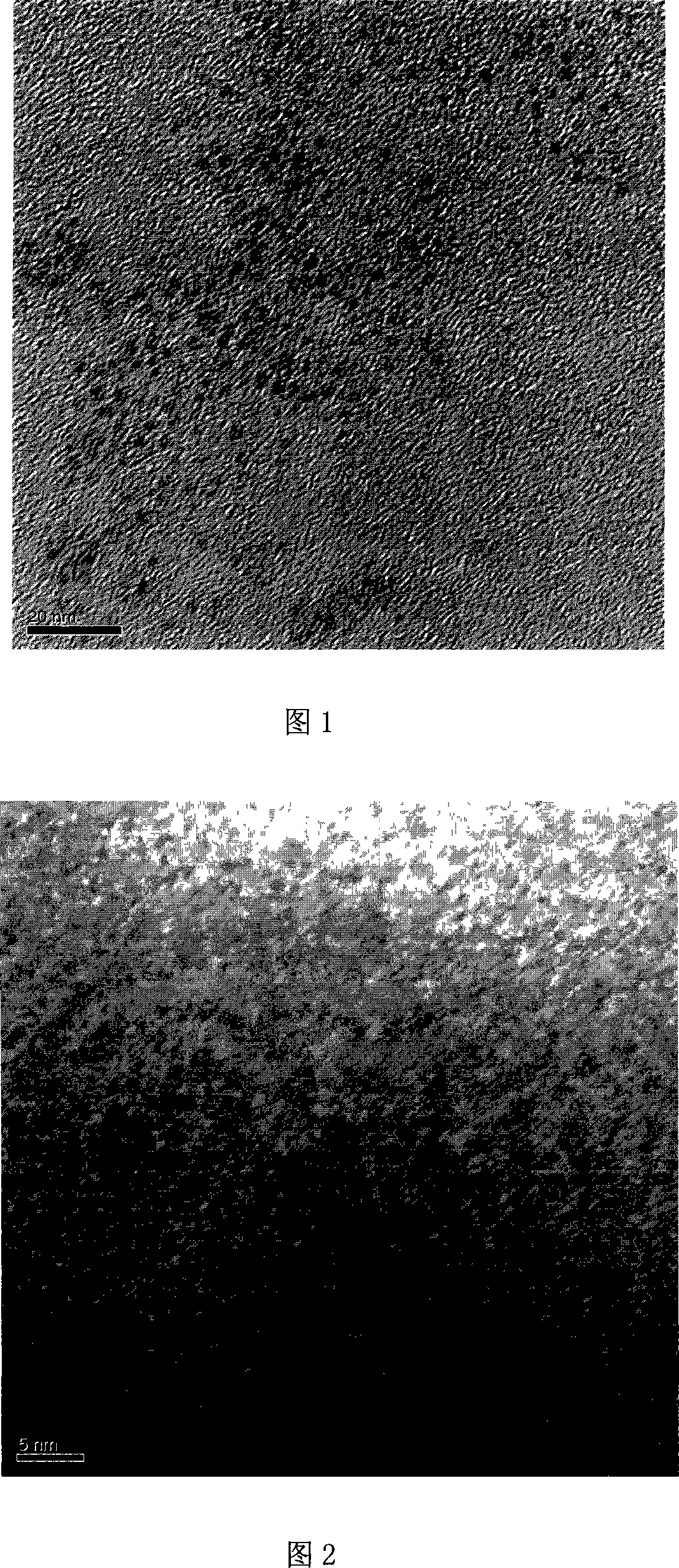

Image

Examples

Embodiment 1

[0029] Add 2.6 liters of n-hexane in a small glass-lined kettle, CMC (carboxymethyl cellulose) 1kg, 0.62 liters of sulfate ester surfactant [the sulfate ester surfactant, such as: fatty alcohol polyoxyethylene ether Sulfate salt (abbreviation: AES), the molecular formula is R-O(CH 2 CH 2 O)nSO 3 Na], N, N methylenebisacrylamide 28g, ammonium persulfate 37g, feed nitrogen into the reactor for 15-30 minutes, start the mixer at 450 rpm, stir for 10-30 minutes, add acrylic acid Sodium aqueous solution (7kg of acrylic acid, 2.7kg of sodium hydroxide, and 7.6kg of water) was then kept at 400 rpm, raised to 60°C for 1 hour, and then heated to 70°C for 4 hours. After the reaction was completed. Cooling water is passed through the jacket of the reaction kettle to cool down to room temperature, and the reaction materials are released. Use a drying machine to separate unreacted substances such as n-hexane, and the separated substances can be reused. The finished product (nano dispers...

Embodiment 2

[0031] Add 3.2 liters of normal hexane, CMC (carboxymethyl cellulose) 1kg, 1.25 liters of sulfate ester surfactants in a small-sized glass-lined kettle [the sulfate ester surfactants, such as: fatty alcohol polyoxyethylene ether Sulfate salt (abbreviation: AES), the molecular formula is R-O(CH 2 CH 2 O)nSO 3 Na], N, N methylenebisacrylamide 14g, ammonium persulfate 26g, feed nitrogen into the reactor for 15-30 minutes, start the mixer at 450 rpm, stir for 10-30 minutes, add acrylic acid Sodium aqueous solution (7kg of acrylic acid, 2.7kg of sodium hydroxide, and 7.6kg of water) was then kept at 400 rpm, raised to 60°C for 1 hour, and then heated to 70°C for 4 hours. After the reaction was completed. Cooling water is passed through the jacket of the reaction kettle to cool down to room temperature, and the reaction materials are discharged. Use a drying machine to separate unreacted substances such as n-hexane, and the separated substances can be reused. The finished produc...

Embodiment 3

[0033] Add 3.8 liters of n-hexane, CMC (carboxymethyl cellulose) 1kg, and 1.85 liters of sulfate ester surfactants in a small glass-lined kettle [sulfate ester surfactants, such as: fatty alcohol polyoxyethylene ether sulfate Salt (abbreviation: AES), the molecular formula is R-O(CH 2 CH 2 O)nSO 3 Na], N, N methylenebisacrylamide 7g, ammonium persulfate 26g, feed nitrogen into the reactor for 15-30 minutes, start the mixer and keep it at 450 rpm for 10-30 minutes, add sodium acrylate aqueous solution (acrylic acid 7kg, sodium hydroxide 2.7kg, water 7.6kg) then keep at 400 rpm, heat up to 60°C for 1 hour, heat up to 70°C for 4 hours, after the reaction is over. Cooling water is passed through the jacket of the reaction kettle to cool down to room temperature, and the reaction materials are discharged. Use a drying machine to separate unreacted substances such as n-hexane, and the separated substances can be reused. The finished product (nano dispersible CMC—acrylic polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com