Method for cleansing exhaust gas of sulfureted hydrogen in low concentration

A hydrogen sulfide, low-concentration technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of difficult to control side reactions, difficult to fully regenerate, and complex composition of washing liquid, saving resources. , Taking into account the effect of recycling and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

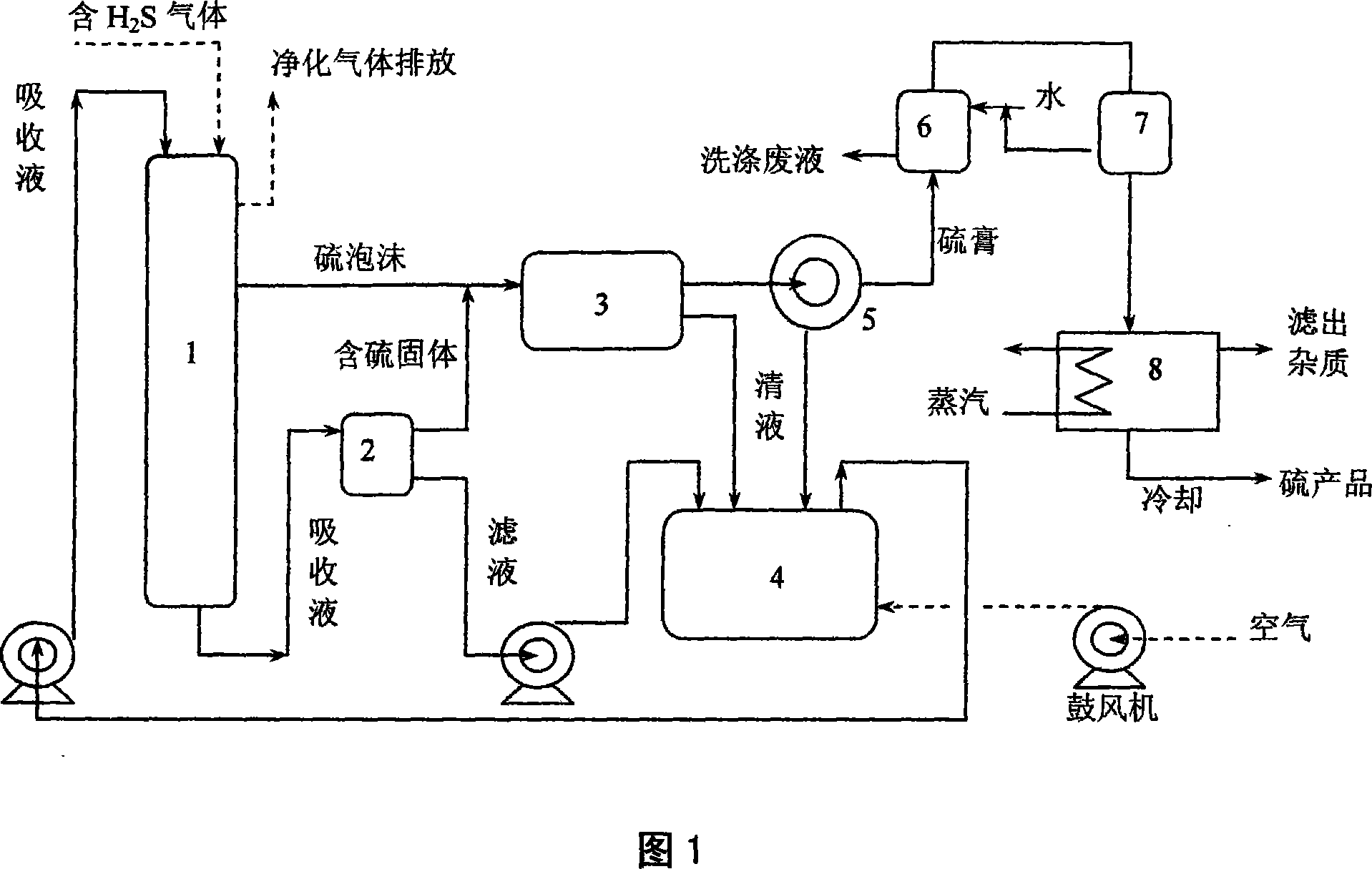

Method used

Image

Examples

Embodiment 1

[0028] Absorption solution: Weigh 1.62 grams of FeCl 3 and 0.72 g of 50% Mn(NO 3 ) 2 solution (element molar ratio Mn:Fe=0.2), dissolved together in 200mL deionized water, fully stirred and dissolved to make Fe 3+ Concentration is the composite ion absorption liquid of 0.05mol / L; Add 2.92 grams of EDTA and 2.18 grams of sulfosalicylic acid as stabilizer (metal ion Fe 3+ and the total molar ratio of the stabilizer is 1:2); with NaCO 3 Adjust the pH value of the solution to 9 to obtain a composite ion absorption solution.

[0029] Pour the prepared absorption solution into the impingement flow reactor, the reaction temperature is controlled at 60-70°C, and the hydrogen sulfide content in the hydrogen sulfide waste gas entering from the reactor inlet is 750mg / m 3 (The volume percent concentration is below 0.1%), the gas flow rate is 200mL / min; the oxygen content volume percent is 10%.

[0030] Purification effect: Under this condition, the purification efficiency of the abso...

Embodiment 2

[0032] Absorption solution: Weigh 1.95 grams of FeCl 3 and 0.69 g of Mn(CH 3 COO) 2 Dissolve in 200mL deionized water (element molar ratio Mn:Fe=0.3), fully stir and dissolve to make Fe 3+ Concentration is the composite ion absorption liquid of 0.06mol / L; Add 13.1 grams of sulfosalicylic acid as stabilizer (metal ion Fe 3+ and the total molar ratio of the stabilizer is 1:5); with NaHCO 3 Adjust the pH of the solution to 8.

[0033] Reaction conditions: Pour the prepared absorption liquid into the impingement flow reactor, and control the reaction temperature at 70-80°C; the hydrogen sulfide content in the hydrogen sulfide waste gas entering from the reactor inlet is 1000mg / m 3 (The volume percent concentration is below 0.1%), the gas flow rate is 200mL / min; the oxygen content volume percent is 15%.

[0034] Purification effect:

[0035] temperature, ℃

Embodiment 3

[0037] Absorption solution: Weigh 1.62 grams of FeCl 3 and 0.87 g of Mn(CH 3 COO) 2 Dissolve in 200mL deionized water (element molar ratio Mn:Fe=0.5), fully stir and dissolve to make Fe 3+ Concentration is the solution of 0.05mol / L; Add 4.36 grams of sulfosalicylic acid and 5.84 grams of EDTA as stabilizer (metal ion Fe 3+ and the total molar ratio of the stabilizer is 1:4); with NaCO 3 and NaHCO 3 Each accounts for 50% to adjust the pH value of the solution to 10.

[0038] Reaction conditions: Pour the prepared absorption liquid into the impingement flow reactor, and control the reaction temperature at 50-60°C; the hydrogen sulfide content in the hydrogen sulfide waste gas entering from the reactor inlet is 1000mg / m 3 , gas flow rate 300mL / min; oxygen content volume percentage 15%.

[0039] Continue the reaction until the purification efficiency drops to 70%, take out the absorption liquid and filter it, and regenerate the filtrate with oxygen drum, adjust the pH value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com