Near-infrared high-transmission rate non-crystal transparent conductive oxide film and its making method

An oxide thin film, transparent conductive technology, which is applied in the manufacture of oxide conductors, non-metallic conductors, cables/conductors, etc., can solve the problems of reduced electrical conductivity and achieve low resistivity, uniform film, and good process stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

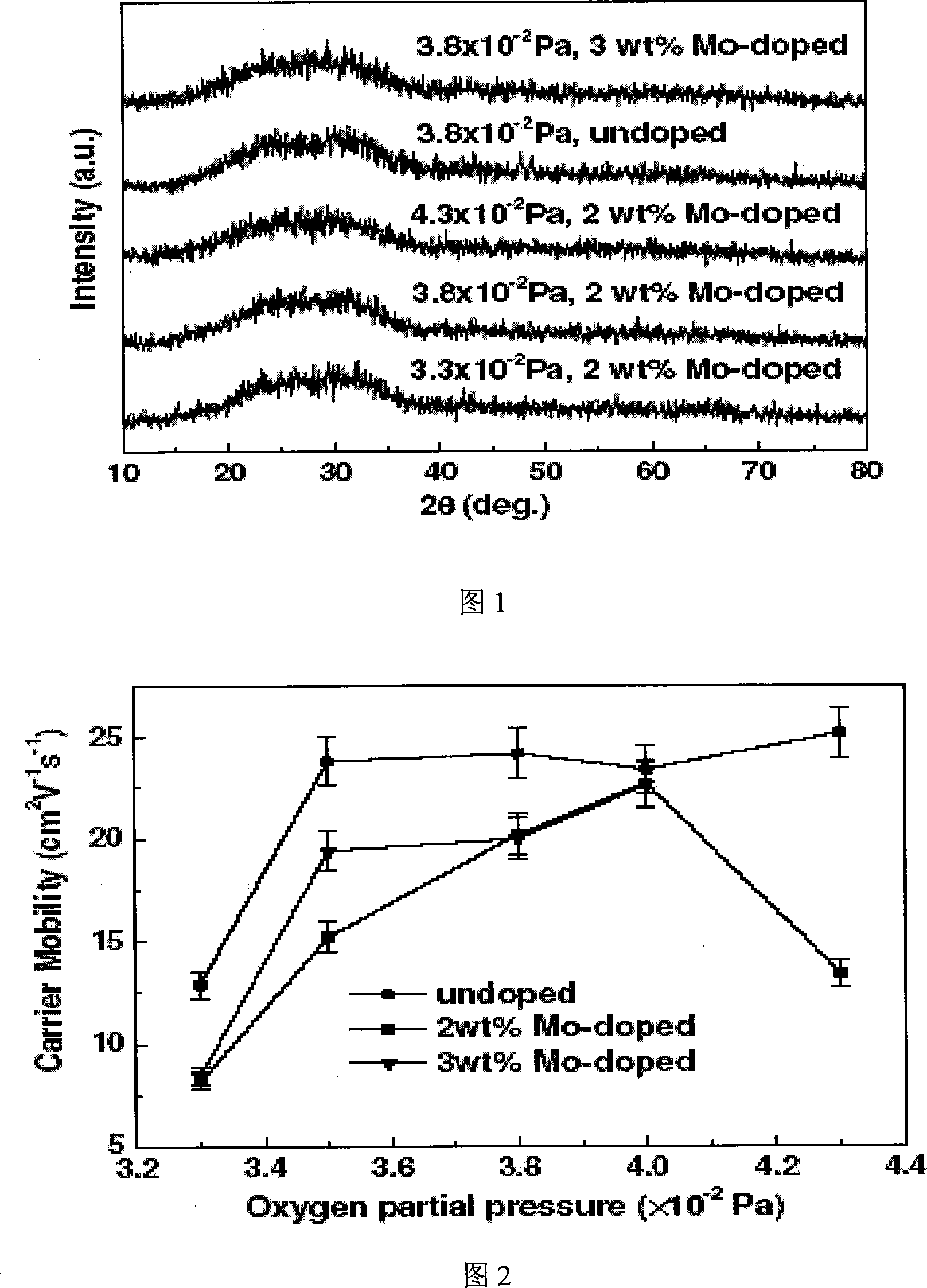

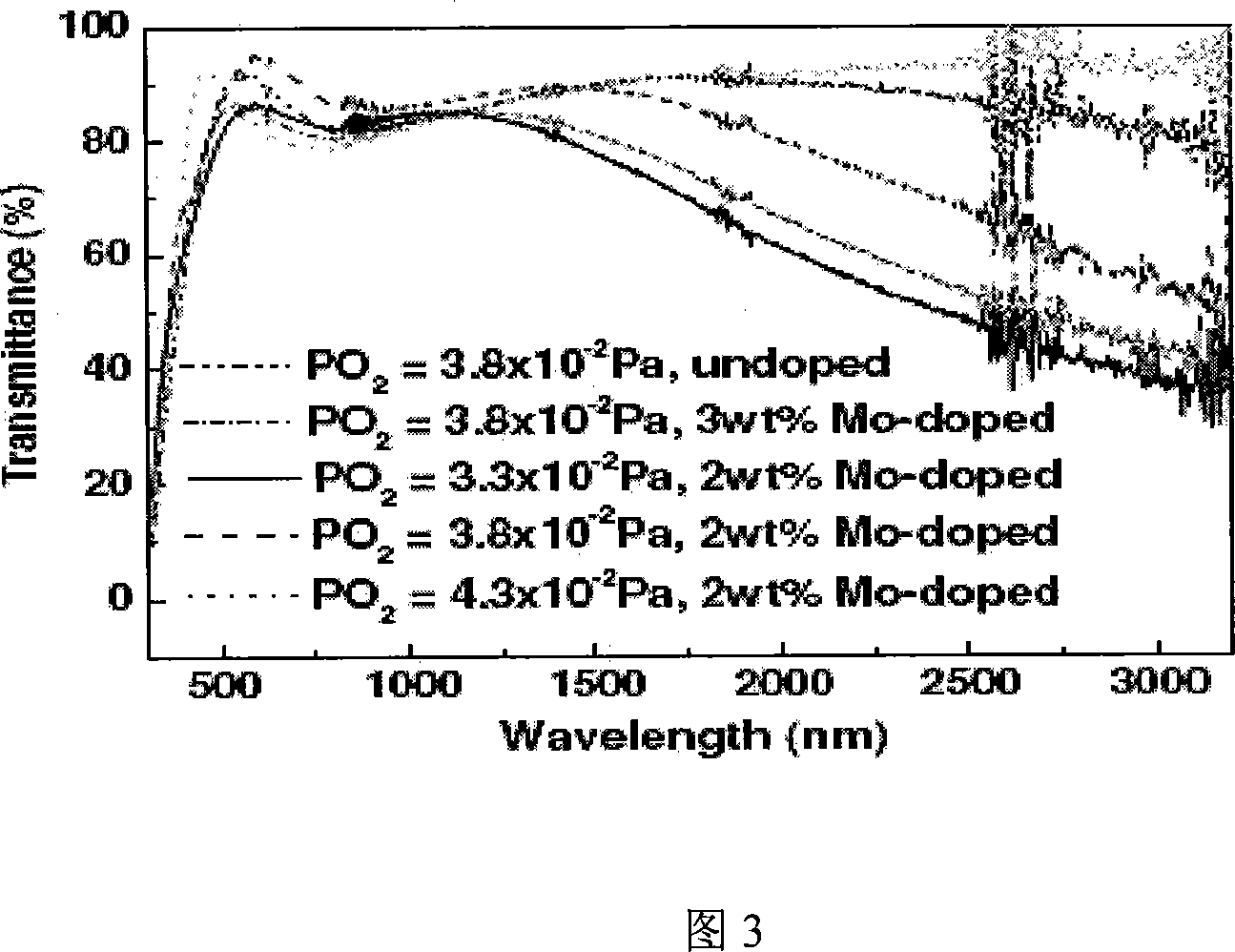

[0021] Example 1, preparation of molybdenum-doped indium oxide target: In metal with a purity of 99.99% is melted into a target, and 2 wt% of molybdenum wire with the same purity of 99.99% is uniformly and symmetrically embedded. The target diameter is 51mm and the thickness is 3.0mm . The substrate is a common glass slide, which has been washed by pure water, alcohol and acetone ultrasonic waves for 15 minutes each.

[0022] Substrate temperature: room temperature. The distance between the target and the substrate was fixed at 50mm. Before film deposition, the reaction chamber was evacuated to less than 2×10 -3 Pa, then the O through the variable air pilot valve 2 And Ar gas into the reaction chamber. The working pressure in the reaction chamber is 2.5×10 -1 Pa, sputtering current is 100mA, sputtering voltage is 350V, control O 2 The partial pressure of the reaction gas is 3.8×10 -2 Pa. Thin films were prepared on ordinary glass slides. The sputtering time is 10 minu...

Embodiment 2

[0023] Example 2, preparation of tungsten-doped indium oxide target: In metal with a purity of 99.99% is melted into a target, and 2 wt% of tungsten wire with the same purity of 99.99% is evenly and symmetrically embedded, and the target diameter is 51mm and the thickness is 3.0mm . The substrate is a common glass slide, which has been washed by pure water, alcohol and acetone ultrasonic waves for 15 minutes each.

[0024] Substrate temperature: room temperature. The distance between the target and the substrate was fixed at 50mm. Before film deposition, the reaction chamber was evacuated to less than 2×10 -3 Pa, then the O through the variable air pilot valve 2 And Ar gas into the reaction chamber. The working pressure in the reaction chamber is 3.0×10 -1 Pa, sputtering current is 150mA, sputtering voltage is 385V, control O 2 The partial pressure of the reaction gas is 3.5×10 -2 Pa. Thin films were prepared on ordinary glass slides. The sputtering time is 8 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com