Light solidifying/heat solidifying one-part welding resistant agent composition

A heat-curable and light-curable technology, applied in the field of heat-curable and heat-curable, can solve problems such as short pot life, reduced dryness to touch, poor development, etc., and achieve high reliability, cost reduction, and excellent storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

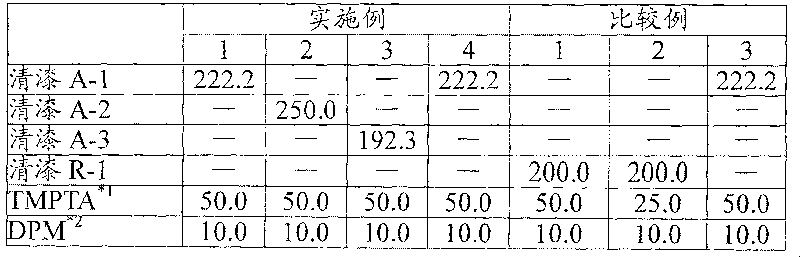

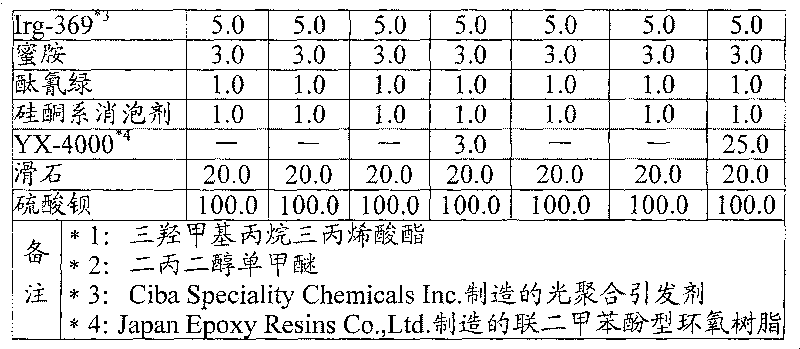

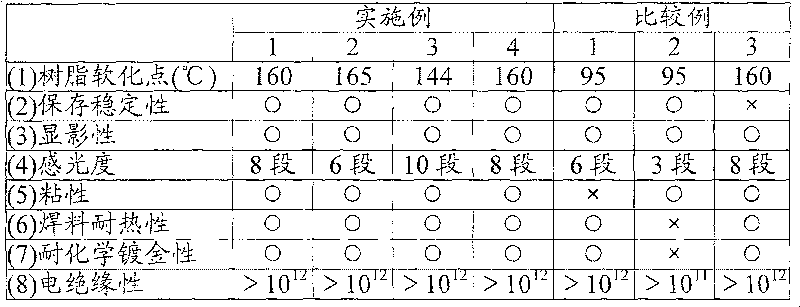

[0059] Hereinafter, although an Example and a comparative example are shown and this invention is concretely demonstrated, it is needless to say that this invention is not limited to a following example. In addition, unless otherwise stated, all the following "parts" represent "parts by mass".

Synthetic example 1

[0061] Add 700.0 g of dipropylene glycol monomethyl ether as a solvent to a flask with a thermometer, a stirrer, a dropping funnel, and a reflux condenser and heat it to 110° C., and dissolve 270.0 g of methacrylic acid and 153.0 g of methyl methacrylate in 3 hours. A mixture of ester, 294.0 g of dipropylene glycol monomethyl ether, and 10.0 g of tert-butyl peroxy-2-ethylhexanoate (Perbutyl O manufactured by NOF Corporation) as a polymerization catalyst was added dropwise thereto, and further stirred at 110° C. After 3 hours, the polymerization catalyst was deactivated to obtain a copolymer resin solution. After cooling the resin solution, 390.0 g of 3,4-epoxycyclohexylmethyl acrylate (CYCLOMER A400 manufactured by DAICEL CHEMICAL INDUSTRIES, LTD.), 5.0 g of triphenylphosphine, and 1.5 g of hydroquinone monomethyl ether were added, Raise the temperature to 100°C and stir to carry out the ring-opening addition reaction of epoxy. The carboxyl group-containing photosensitive res...

Synthetic example 2

[0063] Add 500.0 g of dipropylene glycol monomethyl ether as a solvent to a flask with a thermometer, a stirrer, a dropping funnel, and a reflux condenser and heat it to 110° C., and dissolve 165.0 g of methacrylic acid and 81.6 g of methyl methacrylate in 3 hours. A mixture of ester, 120.4 g of dipropylene glycol monomethyl ether, and 6.2 g of tert-butyl peroxy-2-ethylhexanoate (Perbutyl O manufactured by NOF Corporation) as a polymerization catalyst was added dropwise, followed by stirring at 110° C. After 3 hours, the polymerization catalyst was deactivated to obtain a copolymer resin solution. After cooling the resin solution, 167.0 g of 3,4-epoxycyclohexylmethyl acrylate (CYCLOMERA400 manufactured by DAICEL CHEMICAL INDUSTRIES, LTD.), 4.0 g of triphenylphosphine, and 1.0 g of hydroquinone monomethyl ether were added, and the temperature was raised. to 100°C and stirred for the ring-opening addition reaction of epoxy. The carboxyl group-containing photosensitive resin obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com