Oil smoke filter and manufacturing method therefor

A manufacturing method and filter technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve problems affecting the normal use of products, filter appearance deformation, filter fiber shedding, etc., to achieve excellent environmental protection and safety performance, The effect of high oil mist collection rate and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

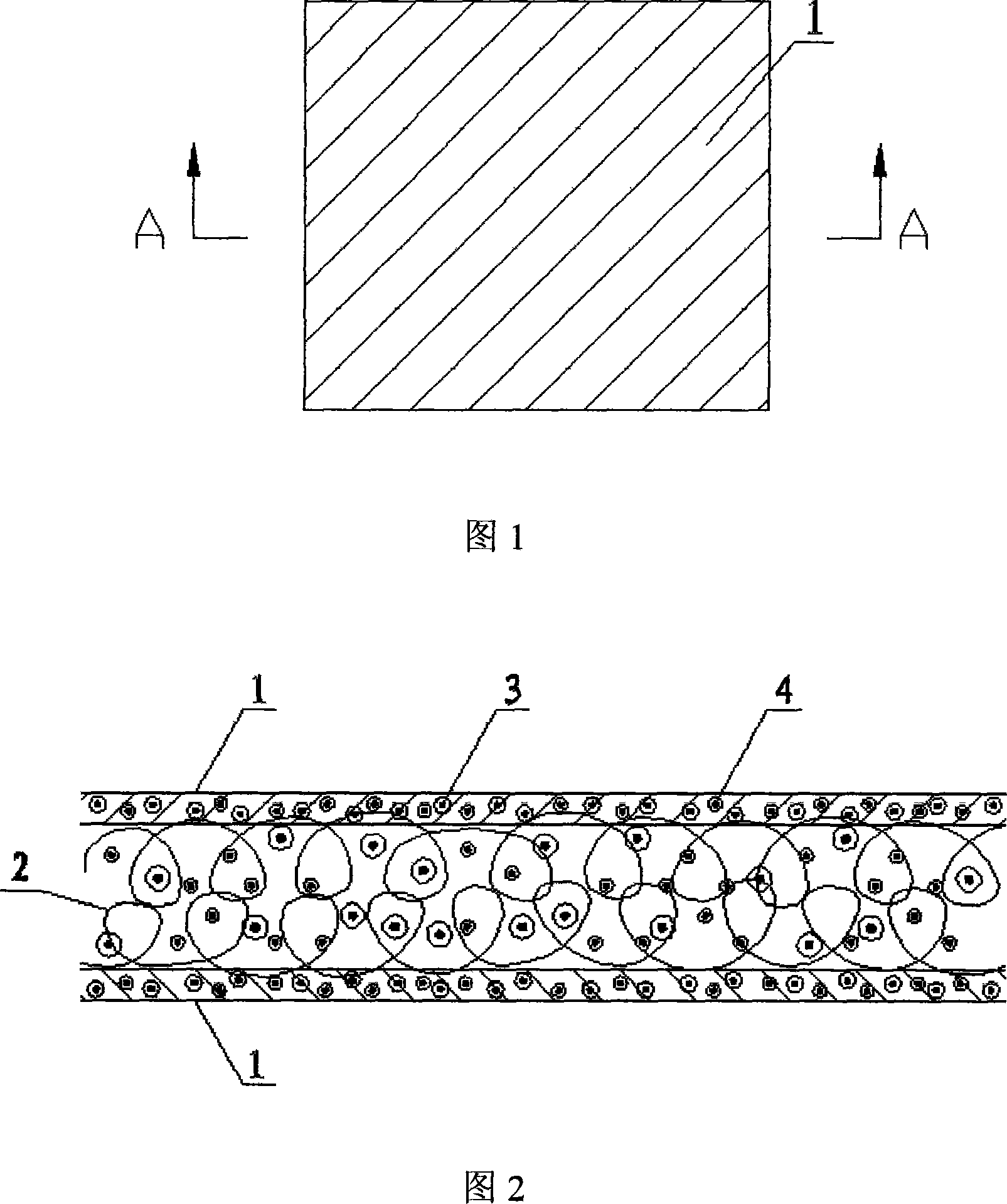

[0029] A kind of oil mist filter and its manufacturing method, as shown in Figure 1 and Figure 2, is to select two layers of skin layer thickness to be 1.5mm, density is 28kg / m 3 ;The thickness of the core layer is 16mm and the density is 5.5kg / m 3 A total of three layers of fluffy glass fiber substrates, and then 8.3% by weight of high-polymerization ammonium phosphate coated with EVA resin, 36% by weight of non-solvent-type acrylic unsaturated polyester resin, silicone oil The powder accounts for 0.1% by weight and mixes evenly. In order to eliminate air bubbles in the binder, avoid virtual sticking and surface defects, add 0.1% by weight of silicon ester defoamer, and add the above solution evenly in the form of spraying. On the surface of the glass fiber, it is fully cured and hardened for 2 minutes through a high-temperature hot air drying line at 230 degrees to obtain a product.

Embodiment 2

[0031] A kind of oil mist filter and its manufacturing method, as shown in Figure 1 and Figure 2, is to choose two layers of skin layer thickness to be 1.0mm, density is 36kg / m 3 ;The thickness of the core layer is 18mm and the density is 5.0kg / m 3 A total of three layers of fluffy glass fiber substrate, and then 13% by weight of melamine phosphate coated with melamine resin, 30% by weight of non-solvent-type acrylic unsaturated polyester resin, silicone oil dispersant It accounts for 0.11% by weight and mixes evenly. In order to eliminate air bubbles in the adhesive, avoid virtual sticking and surface defects, add 0.13% by weight of silicon ester defoamer, and apply the above solution evenly in the form of spraying. The surface of the glass fiber is then placed at room temperature for 45 minutes to make it fully solidified, hardened and shaped, thereby making the product.

Embodiment 3

[0033] An oil mist filter and its manufacturing method, as shown in Figure 1 and Figure 2, is to select two layers of epidermis with a thickness of 1.3mm and a density of 40kg / m 3 ;The thickness of the two core layers is 10mm and the density is 4.0kg / m 3 A total of four layers of fluffy glass fiber substrates, and then the phosphoramidate coated with epoxy resin is 8% by weight, the non-solvent alkyd resin is 28% by weight, and the alkyl polyalcohol ether dispersant is by weight 0.12% by weight and mix evenly. In order to eliminate air bubbles in the binder, avoid virtual sticking and surface defects, add 0.2% by weight of tributyl phosphate defoamer, and add the above solution evenly in the form of spraying. On the surface of the glass fiber, it is fully cured and hardened for 3 minutes by an infrared drying line to make a product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com