Technics for expelling poison for chromic slag

A treatment process and technology for chromium slag, applied in the field of chromium slag detoxification treatment technology, can solve the problems of inability to utilize chromium slag in large quantities, low degree of automation, large floor space, etc., achieve good detoxification effect, reduce equipment investment, reduce The effect of governance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

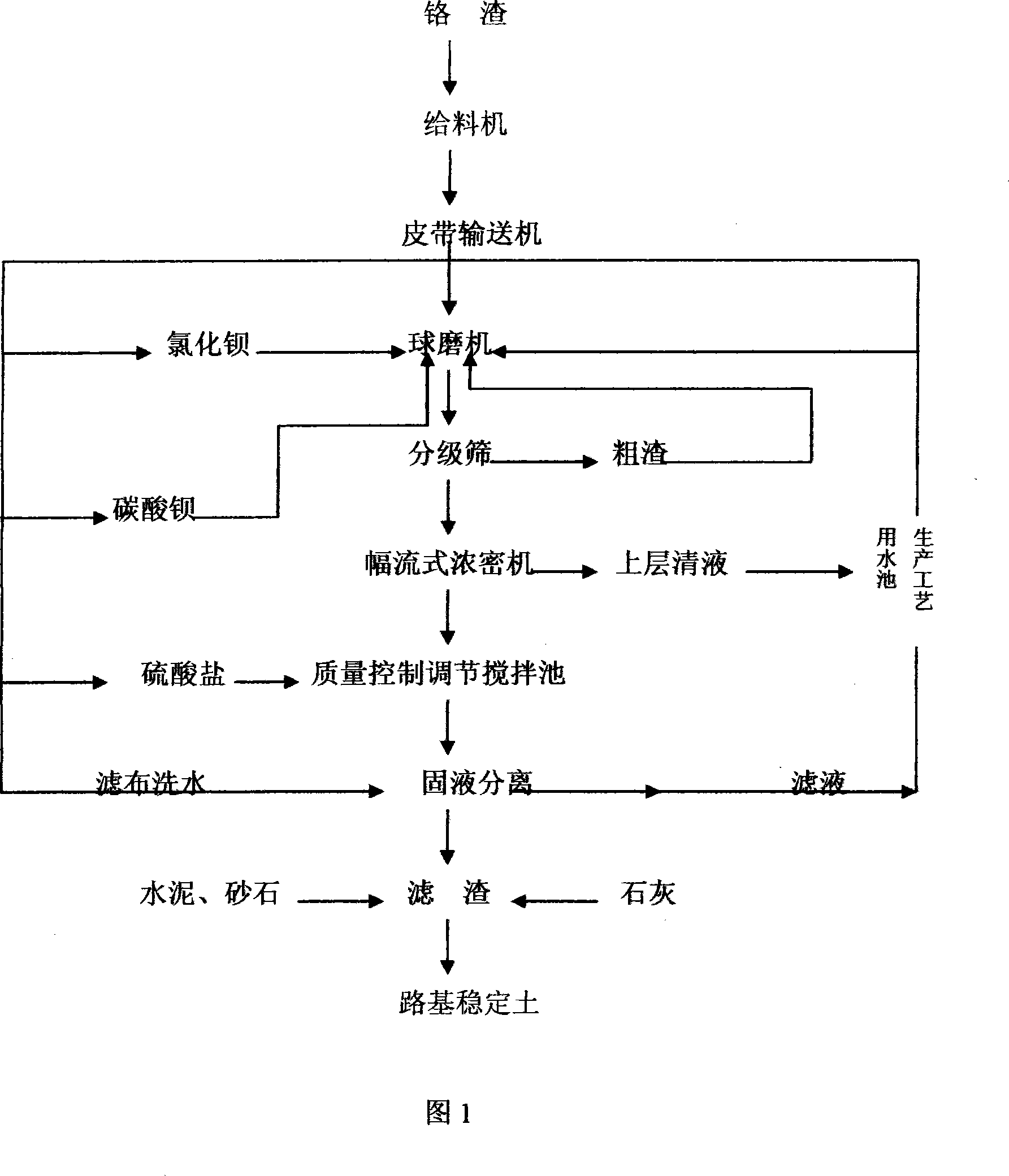

Image

Examples

Embodiment 1

[0016] First, dissolve and dilute the barium chloride with water to form a solution, and dissolve and dilute the barium carbonate to form a suspension, and simultaneously enter the ball mill for mixed grinding with the chromium slag with a water content of 25%. Chromium slag enters the ball mill through the feeder and belt conveyor. When the chromium slag, the solution and the suspension collide with the iron balls of the ball mill in the ball mill to crush the chromium slag, the hexavalent chromium in the chromium slag is continuously dissolved during the collision crushing process and fully contacts with the barium ions in the solution. Rapid reaction, pulverization, ball milling, and dissolution to generate water-insoluble barium chromate.

[0017] All the materials after the ball milling reaction are sieved through a 300 mesh / inch grading sieve, and the materials with a moisture content of 85% through the grading sieve enter the radial flow thickener for material concentra...

Embodiment 2

[0020] The difference from Example 1 is that the barium chloride is firstly dissolved and diluted with water to form a solution, and the barium carbonate is dissolved and diluted to form a suspension, and the chromium slag with a water content of 21% enters the ball mill for mixed grinding. The materials after the ball milling reaction are all sieved through a 200 mesh / inch grading sieve, the moisture content of the material passing through the grading sieve is 83%, and the thickened material is a slurry with a moisture content of 48%. Add an appropriate amount of ferrous sulfate to the slurry in the quality control adjustment mixing tank. The water content of the treated filter residue was 33%.

Embodiment 3

[0022] The difference from Example 1 is that the barium chloride is firstly dissolved and diluted with water to form a solution, and the barium carbonate is dissolved and diluted to form a suspension, and the chromium slag with a water content of 18% enters the ball mill for mixed grinding. The materials after the ball milling reaction are all sieved through a grading sieve of 120 mesh / inch, the moisture content of the material passing through the grading sieve is 80%, and the thickened material is a slurry with a moisture content of 45%. The water content of the filter residue after treatment is 30%.

[0023] Beneficial effect

[0024] In the roadbed stabilized soil production test of Examples 1, 2, and 3, press 71kg of filter residue, 50kg of river sand, 6.5kg of lime, and 10.5kg of cement, mix and stir evenly, and press it into a cube with a thickness of 30cm. After 7 days, test Its compressive strength is more than 5Mpa, compactness CBR is more than 96%, and the hexavalen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com