Ferrum oxidate nano magnetic material and method for preparing the same

A technology of nano-magnetic materials and oxides, applied in the field of iron oxide nano-magnetic materials and its preparation, to achieve the effects of convenient operation, simple preparation process, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

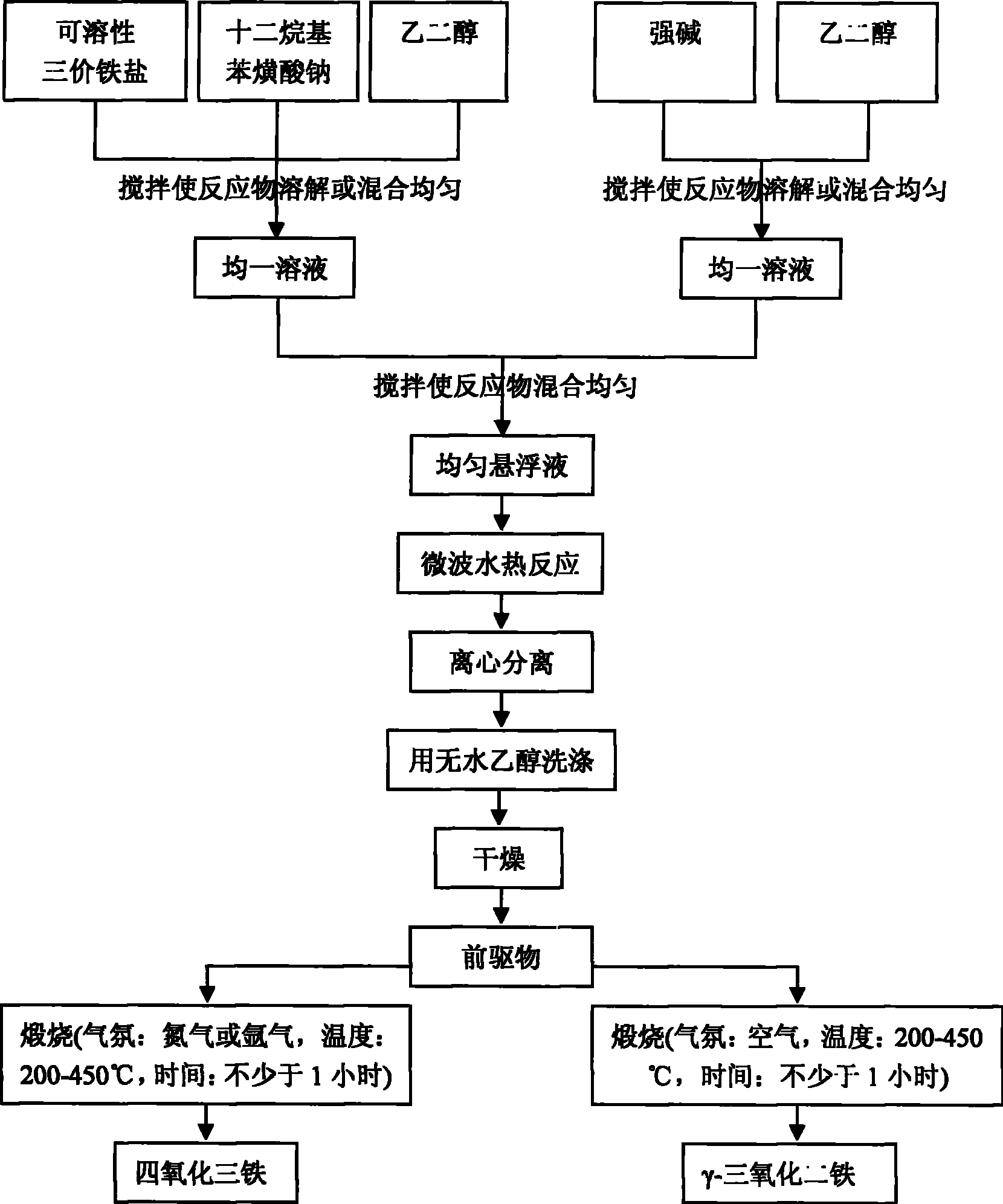

Method used

Image

Examples

Embodiment 1

[0025] At room temperature, 0.541 g of ferric chloride hydrate and 0.600 g of sodium dodecylbenzenesulfonate were dissolved in 20 ml of ethylene glycol, stirred and dissolved at room temperature to obtain a uniformly dispersed solution. In addition, 0.160 g of sodium hydroxide was dissolved in 10 ml of ethylene glycol, stirred and dissolved at room temperature, and a uniformly dispersed solution was obtained. The above two solutions were mixed and stirred at room temperature to obtain a uniformly dispersed suspension. Take 20 ml of the suspension and transfer it into a polytetrafluoroethylene liner (the capacity of the liner is 60 ml), and seal it. Put the inner lining into a microwave hydrothermal reaction device and keep it warm at 200°C for 90 minutes. After the reaction system was naturally cooled to room temperature, the product was taken out, and the product was separated by centrifugation. The separated product was washed three times with absolute ethanol, and dried in...

Embodiment 2

[0027] At room temperature, 0.541 g of ferric chloride hydrate and 0.600 g of sodium dodecylbenzenesulfonate were dissolved in 20 ml of ethylene glycol, stirred and dissolved at room temperature to obtain a uniformly dispersed solution. In addition, 0.160 g of sodium hydroxide was dissolved in 10 ml of ethylene glycol, stirred and dissolved at room temperature, and a uniformly dispersed solution was obtained. The above two solutions were mixed and stirred at room temperature to obtain a uniformly dispersed suspension. Take 20 ml of the suspension and transfer it into a polytetrafluoroethylene liner (the capacity of the liner is 60 ml), and seal it. Put the inner lining into a microwave hydrothermal reaction device and keep it warm at 200°C for 90 minutes. After the reaction system was naturally cooled to room temperature, the product was taken out, and the product was separated by centrifugation. The separated product was washed three times with absolute ethanol, and dried in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com