Method for comprehensive utilization of vanadium titanium and iron ore concentrate by using rotary hearth furnace reduction-grinding - separation

A vanadium-titanium-iron concentrate and rotary hearth furnace technology, applied in the metallurgical field, can solve the problems of increased energy consumption, long reduction time and the like, and achieve the effects of low cost, short reduction time and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

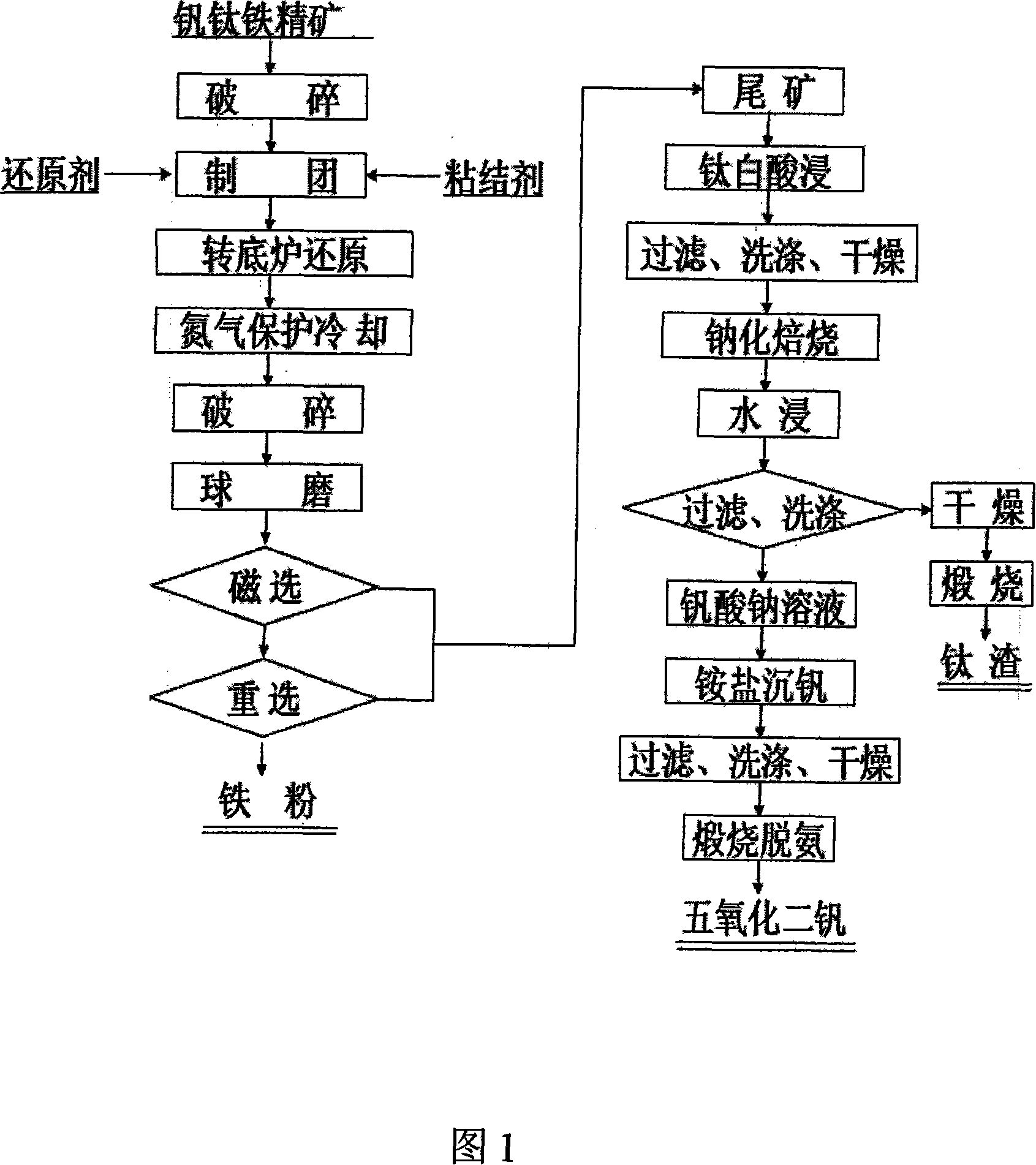

Image

Examples

Embodiment 1

[0027] 1. The chemical composition weight percentage of vanadium-titanium iron ore concentrate is as follows: TFe 58.44~59.13%, TiO 2 10.47~12.83, TiO 2 0.61~0.65, Cr 2 o 3 0.078~0.084%, SiO 2 2.31~2.58%, Al 2 o 3 2.36~2.64%, CaO 1.24~1.40%, MgO 2.37~2.55%, MnO 0.18~0.23%, S 0.03~0.05% and P 0.0014~0.0018%, the rest is ash or other trace components, the total amount is 100%.

[0028] 2. Process conditions: 10,000g of vanadium-titanium iron concentrate is ground to less than 120 mesh, of which -140+180 mesh accounts for 80%, and 19% of the original ore weight is added with a particle size of -180 mesh, accounting for 70% of coke and 2.5% of the original ore weight. Calcium lignosulfonate binder and vanadium-titanium iron concentrate were lubricated and ground for 0.5h, and pellets with a diameter of 20-30mm were made into pellets with a spherical egg forming machine, dried at 250°C for 4h, and reduced in a rotary hearth furnace, and the temperature was controlled at 13...

Embodiment 2

[0030]1. The chemical composition weight percentage of vanadium-titanium iron concentrate is as follows: TFe 57.01~58.82%, TiO 2 11.31~12.14, V 2 o 3 0.61~0.65, Cr 2 o 3 0.054~0.067%, SiO 2 2.12~2.45%, Al 2 o 3 2.02~2.49%, CaO 1.14~1.58%, MgO 2.67~2.89%, MnO 0.12~0.20%, S 0.02~0.04% and P 0.0013~0.0016%, the rest is ash or other trace components, the total amount is 100%.

[0031] 2. Process conditions: 20,000g of vanadium-titanium iron concentrate is ground to -140+180 mesh, accounting for 80%, adding coal powder with a particle size of -180 mesh of 19% of the original ore weight, accounting for 70% of the original ore weight, and adding 4% of the original ore weight of solid lignin Calcium sulfonate binder and vanadium-titanium-iron concentrate were lubricated and ground for 0.5h, and pellets with a diameter of 25-40mm were made into pellets with a spherical egg forming machine, dried at 250°C for 4h, and quickly reduced in a rotary hearth furnace, and the tempera...

Embodiment 3

[0033] 1. The chemical composition weight percentage of vanadium-titanium iron concentrate is as follows: TFe 56.54~58.01%, TiO 2 11.39~12.94%, TiO 2 0.58~0.62%, Cr 2 o 3 0.081~0.094%, SiO 2 2.71~2.99%, Al 2 o 3 2.64~2.97%, CaO 1.54~1.77%, MgO 2.64~2.98%, MnO 0.17~0.20%, S 0.04~0.06% and P 0.0011~0.0014%, the rest is ash or other trace components, the total amount is 100%.

[0034] 2. Process conditions: 50,000g of vanadium-titanium iron concentrate is ground to -140+180 mesh, accounting for 80%, adding 22% of the original ore weight with a particle size of -200 mesh, accounting for 60% of charcoal, and adding 5% of the original ore weight of solid lignosulfonic acid Calcium binder and vanadium-titanium-iron concentrate are lubricated for 0.5h, and pellets with a diameter of 30-40mm are made into pellets with a ball forming machine, dried at 250°C for 4h, and reduced in a rotary hearth furnace with the temperature controlled at 1350±50°C. 20min. After reduction, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com