Biological oil and method for preparing the same by biomass magnetic stabilization fluidized bed reactor middle-temperature fast hot crack

A fluidized bed reactor and bio-oil technology, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, can solve the problems of complex operation and maintenance of equipment, high heat and mass transfer rate, and high bio-oil yield, and reduce the The effect of material residence time, high reaction energy efficiency and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

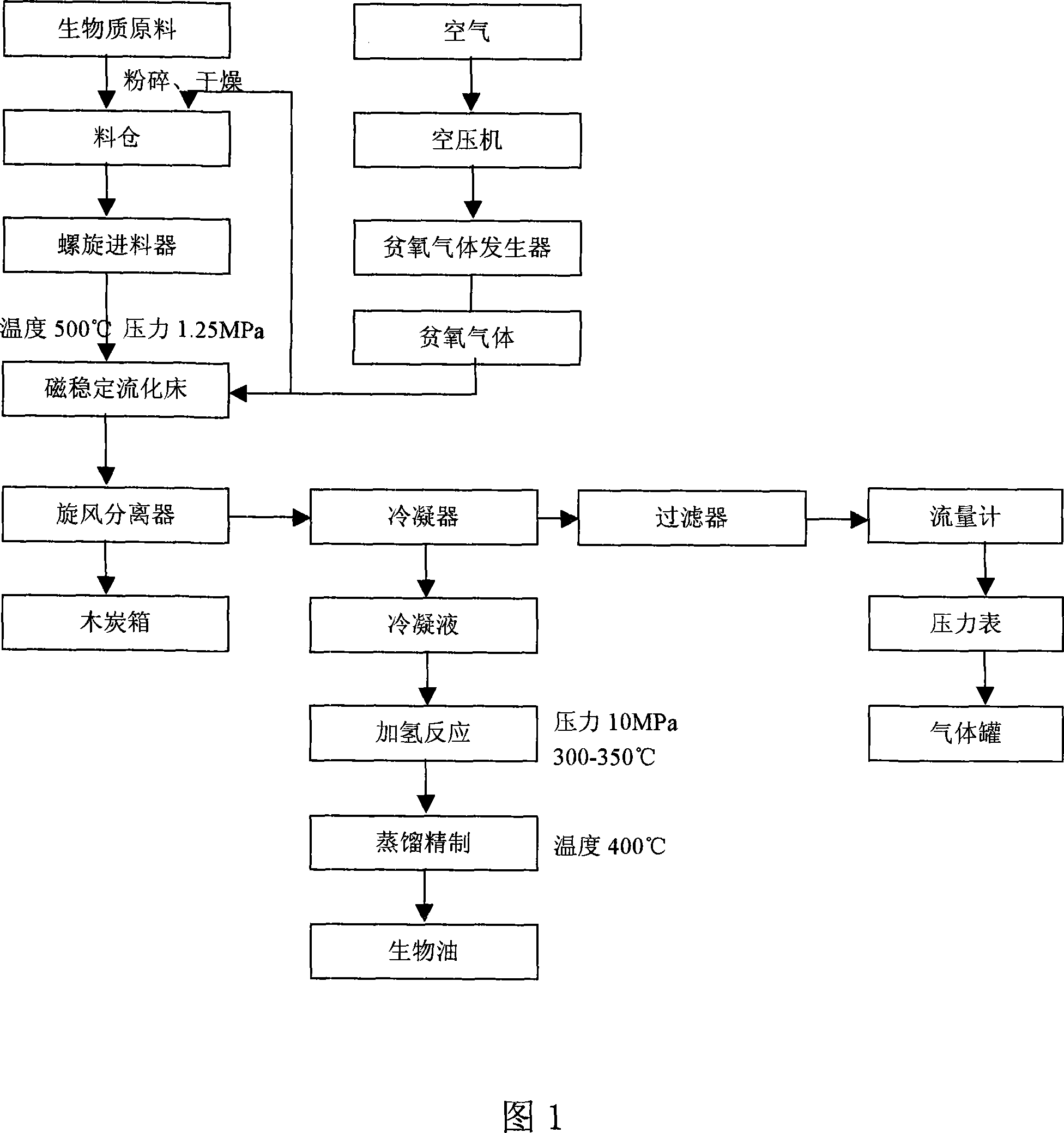

[0023] The technology of the present invention uses biomass as raw material and adopts medium-temperature rapid thermal cracking in a magnetically stable fluidized bed reactor to produce bio-oil. Obtain bio-oil (process flow diagram as shown in Figure 1). Now take corn cob as raw material, the specific content of the present invention is described in detail:

[0024] (1) Raw material pretreatment:

[0025] The corncobs are collected, then pulverized, dried (moisture content < 8%) and made into material granules with a particle size of less than 2 mm.

[0026] (2) Preparation of oxygen-poor gas:

[0027] The air is introduced into the oxygen-depleted gas generator by the air compressor, and the oxygen-depleted gas produced is pressed into the buffer tank. The gas coming out of the gas buffer tank is divided into two paths by the rotameter: the main path with a larger flow enters the bottom of the reactor for preheating, and enters the reactor through the gas distribution pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com