Inorganic EL display insulation media and its making method

A technology of insulating medium and manufacturing method, which is applied in the field of inorganic thin film electroluminescent display, and can solve the problems of reducing the interface polarization electric field, destroying the lower dielectric layer and light-emitting layer, and low brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

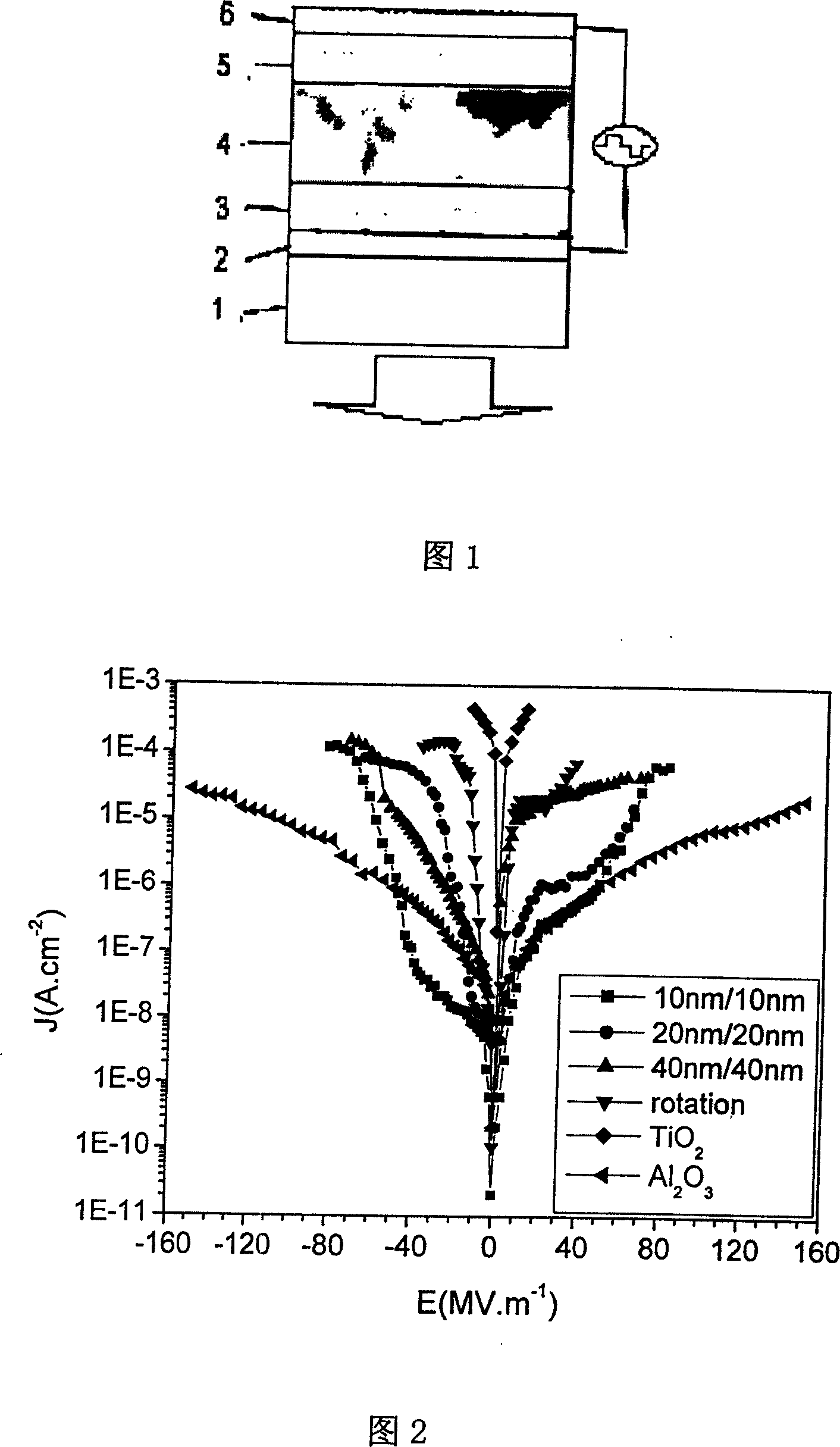

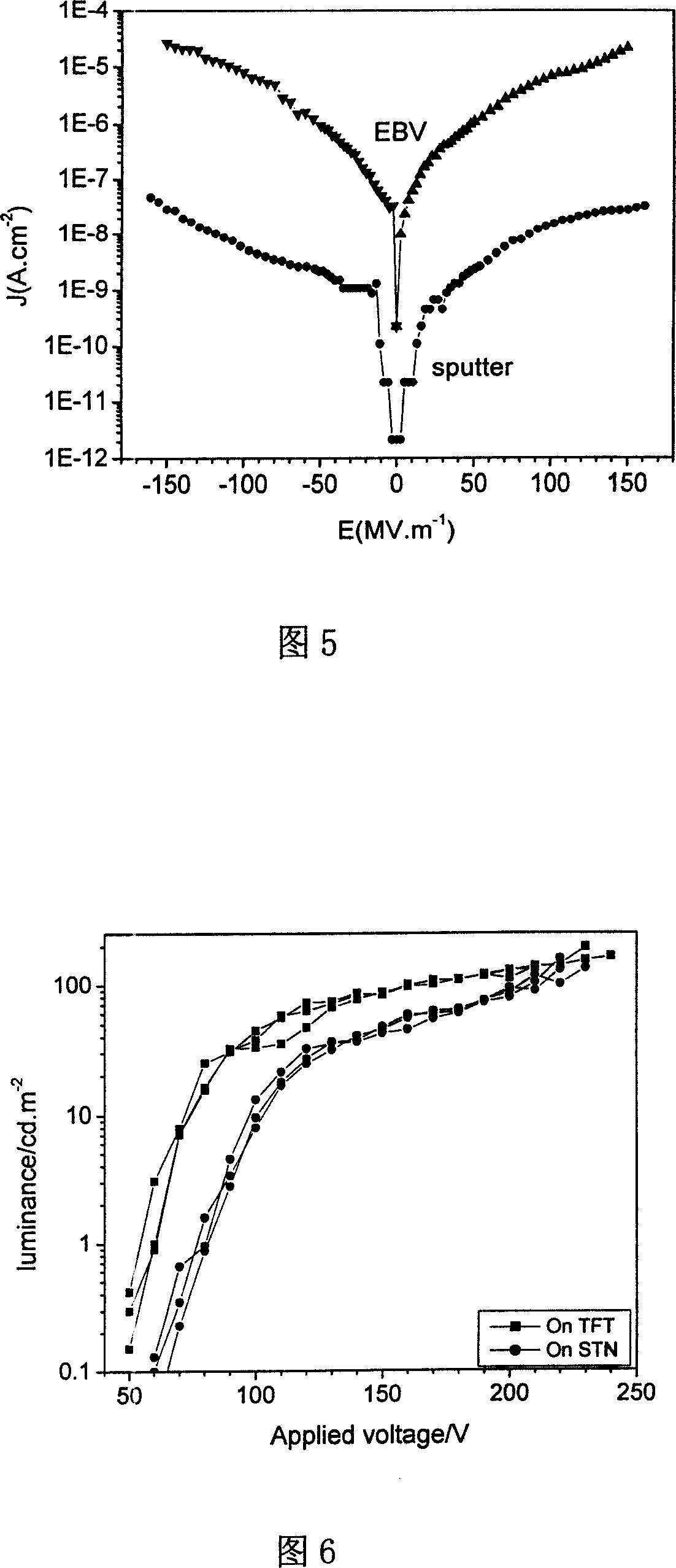

[0102] The structure of the device is ITO / BaTiO 3 (863nm)) / ZnS:Mn(300nm) / ATO(785nm) / Al. The substrate is NSG's STN-LCD glass or Corning's TFT-LCD glass. The lower electrode is an ITO electrode with a thickness of 150nm photolithography. The upper electrode is an electron-beam-evaporated aluminum electrode with a thickness of 150 nm. BaTiO 3 The deposition conditions: the background vacuum is 3.0×10 -3 Pa, the oxygen pressure is 3.0×10 -2 Pa, the rate is 2.5 Ȧ s -1 , the substrate temperature is 180°C. ATO deposition conditions: the background vacuum is 3.6×10 -3 Pa, O 2 Pressed to 3.2×10 -2 Pa, the substrate temperature is about 100°C, Al 2 o 3 The source evaporation rate is 3 Ȧ s -1 ,TiO 2 The source evaporation rate is 2.5 Å·s -1 , the substrate rotation rate is 1 rotation per 18 seconds. TiO 2 Cumulative thickness of 385nm, Al 2 o 3 The cumulative thickness was 400 nm. Deposition conditions of ZnS:Mn: the background vacuum is 3.9×10 -3 Pa, substrate temp...

Embodiment 2

[0105] The structure of the device is STN glass / ITO / BaTiO 3 (300nm)) / ZnS:Mn(382nm) / ATO(730nm) / Al. Upper electrode Al, lower electrode ITO, BaTiO 3 , ZnS:Mn, the preparation conditions of ATO are the same as example 1. Fig. 7 shows the L-V relationship of one of the four pixels. L at 200Hz 50 209cd·m -2 , The optical threshold voltage is 110V.

Embodiment 3

[0107] Prepared a 2-inch 128×64ZnS:Mn matrix screen with a structure of STN glass / ITO / BaTiO 3 (860nm)) / ZnS:Mn(500nm) / ATO(730nm) / Al. The evaporation and annealing conditions of upper electrode Al, lower electrode ITO, ZnS:Mn, ATO are the same as Example 1. Evaporated BaTiO 3 The substrate temperature at the time was 112° C., and all the other conditions were the same as in Example 1. BaTiO 3 Before deposition, the substrate was coated with O 2 Plasma treatment was performed for 10 min to eliminate the photoresist that may remain on the surface of the substrate. L obtained at 200Hz 50 5cd·m -2 , The optical threshold voltage is 160V. Figure 8 shows the L-V curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com