Method for preparing monochloroethylene carbonate

A technology of monochloroethylene carbonate and ethylene carbonate, which is applied in the field of preparation of monochloroethylene carbonate, can solve the problem of low yield of monochloroethylene carbonate products, low yield of monochloroethylene carbonate, and the inability to enter industrial production and other problems, to achieve the effect of low equipment requirements, improved cycle performance, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

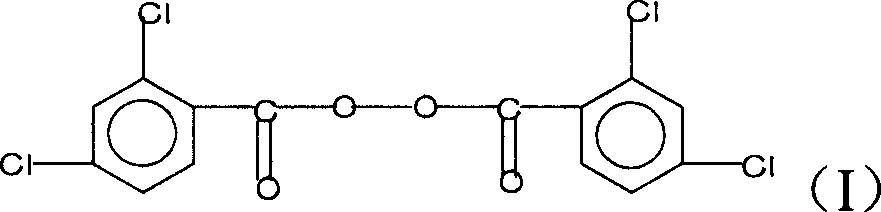

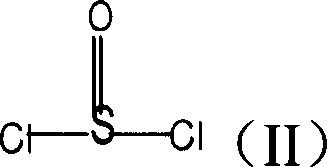

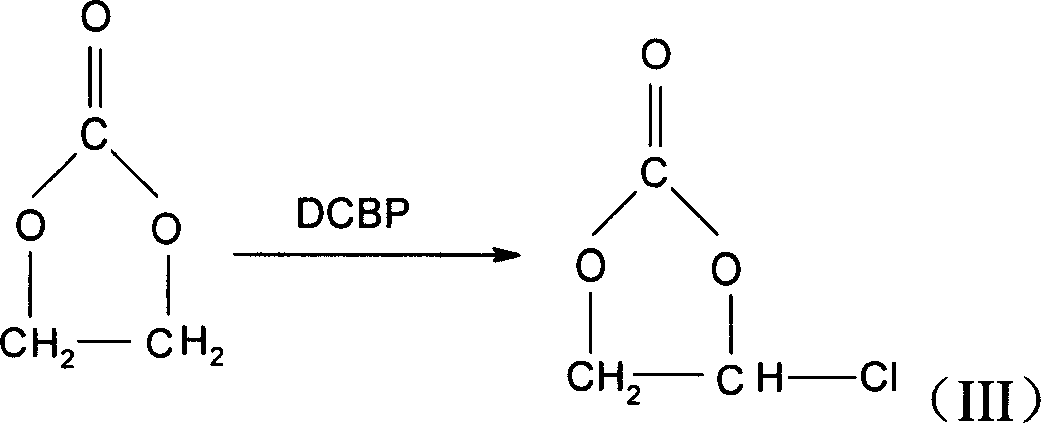

[0015] The method for preparing chloroethylene carbonate of the present invention can be represented by following chemical reaction formula (III):

[0016]

[0017] In the above reaction, there is no special limitation on the amount of the initiator added, which can be the amount of conventional initiators. Sulfuryl chloride and ethylene carbonate can be added according to the stoichiometric ratio, and excessive sulfuryl chloride can also be added, and excessive ethylene carbonate can also be added. In order to make the reaction more thorough, one of them is usually excessive. Considering that the sulfuryl chloride raw material is easy to get And it is easy to remove from the product after the reaction, so sulfuryl chloride is preferably in excess. Preferably, the weight ratio of the 2,4,2,4-tetrachlorobenzoyl peroxide, sulfuryl chloride and ethylene carbonate is (0.001-0.05): (1-2): 1, more preferably ( 0.001-0.0075):(1-2):1.

[0018] The present invention does not have ...

Embodiment 1

[0034] This embodiment is used to illustrate the preparation method of chloroethylene carbonate provided by the present invention.

[0035] Add 100 grams of ethylene carbonate to a 500 ml four-necked round-bottomed flask equipped with a stirrer, put the round-bottomed flask in a water bath, then slowly feed dry nitrogen into the device for 10 minutes, heat the water bath to make the temperature in the flask When rising to 50°C, start to add 158.5 grams of sulfuryl chloride dropwise under stirring, then add 1.08 grams of DCBP dissolved in 50 milliliters of benzene into the four-necked round-bottomed flask at the same time after adding 20 milliliters of sulfuryl chloride dropwise. After 3 hours of reaction, the above reaction solution was transferred to a 500 ml single-necked flask for vacuum distillation, and 140 grams of colorless fractions with a system pressure of 3 mm Hg and a temperature of 88-92° C. were collected. 140 g of the colorless fraction obtained were subjected t...

Embodiment 2

[0037] This embodiment is used to illustrate the preparation method of chloroethylene carbonate provided by the present invention.

[0038] Add 100 grams of ethylene carbonate to a 500 ml four-necked round-bottomed flask equipped with a stirrer, put the round-bottomed flask into a water bath, then slowly feed dry argon into the device for 10 minutes, heat the water bath to make the When the temperature rose to 90°C, 288.5 grams of sulfuryl chloride began to be added dropwise under stirring, and then 0.88 grams of DCBP dissolved in 50 milliliters of benzene was added dropwise to the four-necked round-bottomed flask after adding 20 milliliters of sulfuryl chloride dropwise. Both were 4.5 ml / min. After 3 hours of reaction, the above reaction solution was transferred to a 500 ml single-necked flask for vacuum distillation, and 141 grams of colorless fractions with a system pressure of 3 mmHg and a temperature of 88-92°C were collected. The resulting 141 g colorless fraction was su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com