Royal jelly enzymolysis product with moisture-absorbing moisture-keeping function

A technology of enzymatic hydrolysis product and moisturizing function, applied in the field of royal jelly enzymatic hydrolysis product, can solve the problems of low added value of products and deterioration of trade conditions, achieve good moisture absorption and moisturizing performance, increase added value, and strengthen the effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Weigh 25g of royal jelly, add water to dissolve, adjust the pH to 7, control the substrate concentration to 20%, add trypsin equivalent to 1.5% of the substrate concentration, control the enzymolysis temperature at 50°C, and the enzymolysis time for 7 hours. Keep the solution homogeneous. After the reaction, the system was placed in a water bath at 85° C. for 20 minutes to inactivate the enzyme, and the obtained product was filtered and freeze-dried.

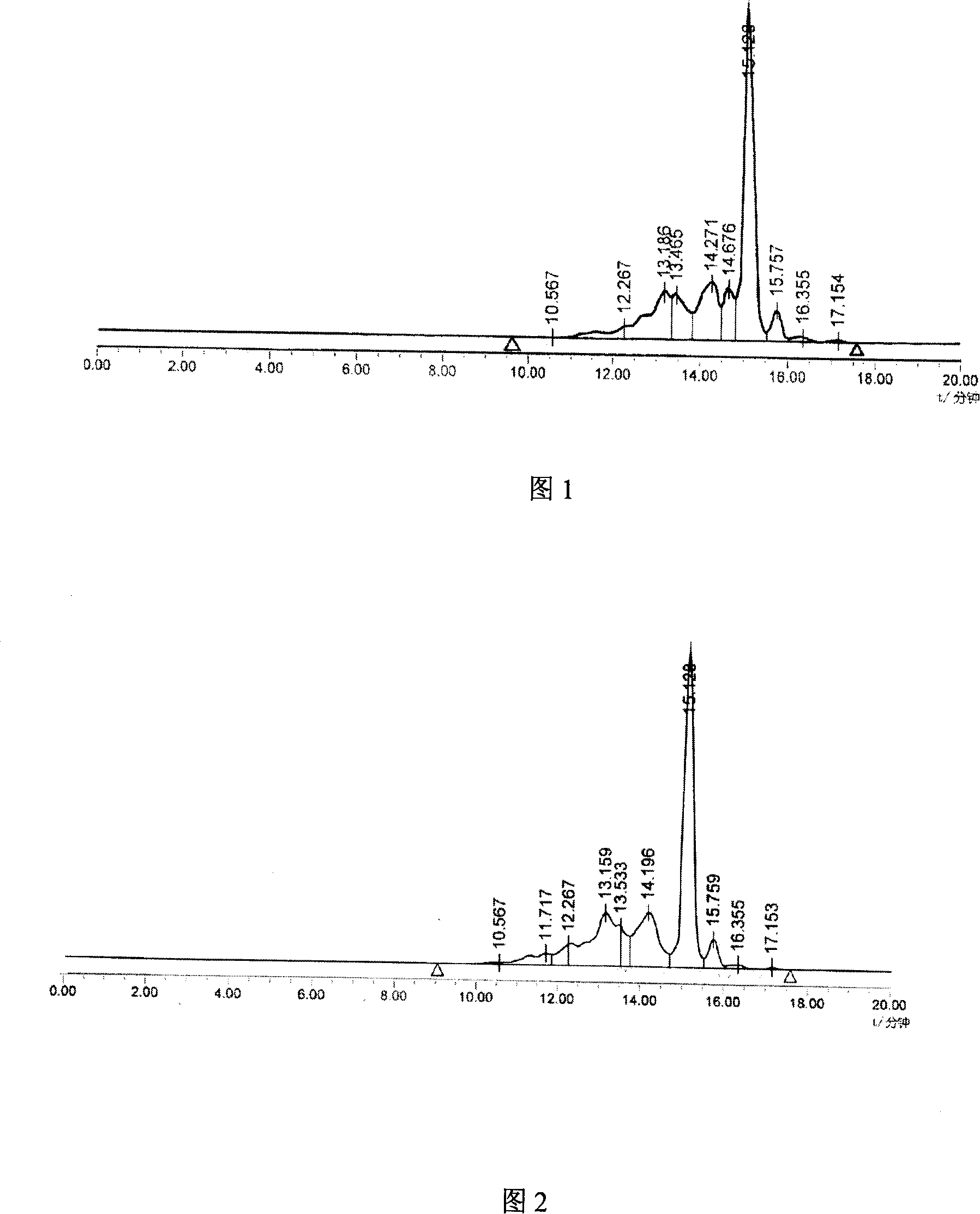

[0015] Respectively take ribonuclease A (molecular weight 13700), insulin (molecular weight 5800), thymosin α1 (molecular weight 3108), somatostatin (molecular weight 1638) as molecular weight standard solutions, high performance liquid chromatography, the obtained Products with a relative molecular weight <2000D accounted for 96.25% of the total, and products with a relative molecular weight of 2000D-6000D accounted for 3.71%. See Figure 1 for the results.

Embodiment 2

[0017] Weigh 25g of royal jelly, add water to dissolve, adjust the pH to 8, control the substrate concentration to 8%, add trypsin equivalent to 0.5% of the substrate concentration, control the enzymolysis temperature to 40°C, and the enzymolysis time to 5 hours. Keep the solution homogeneous. After the reaction, the system was placed in a water bath at 85° C. for 20 minutes to inactivate the enzyme, and the obtained product was filtered and freeze-dried.

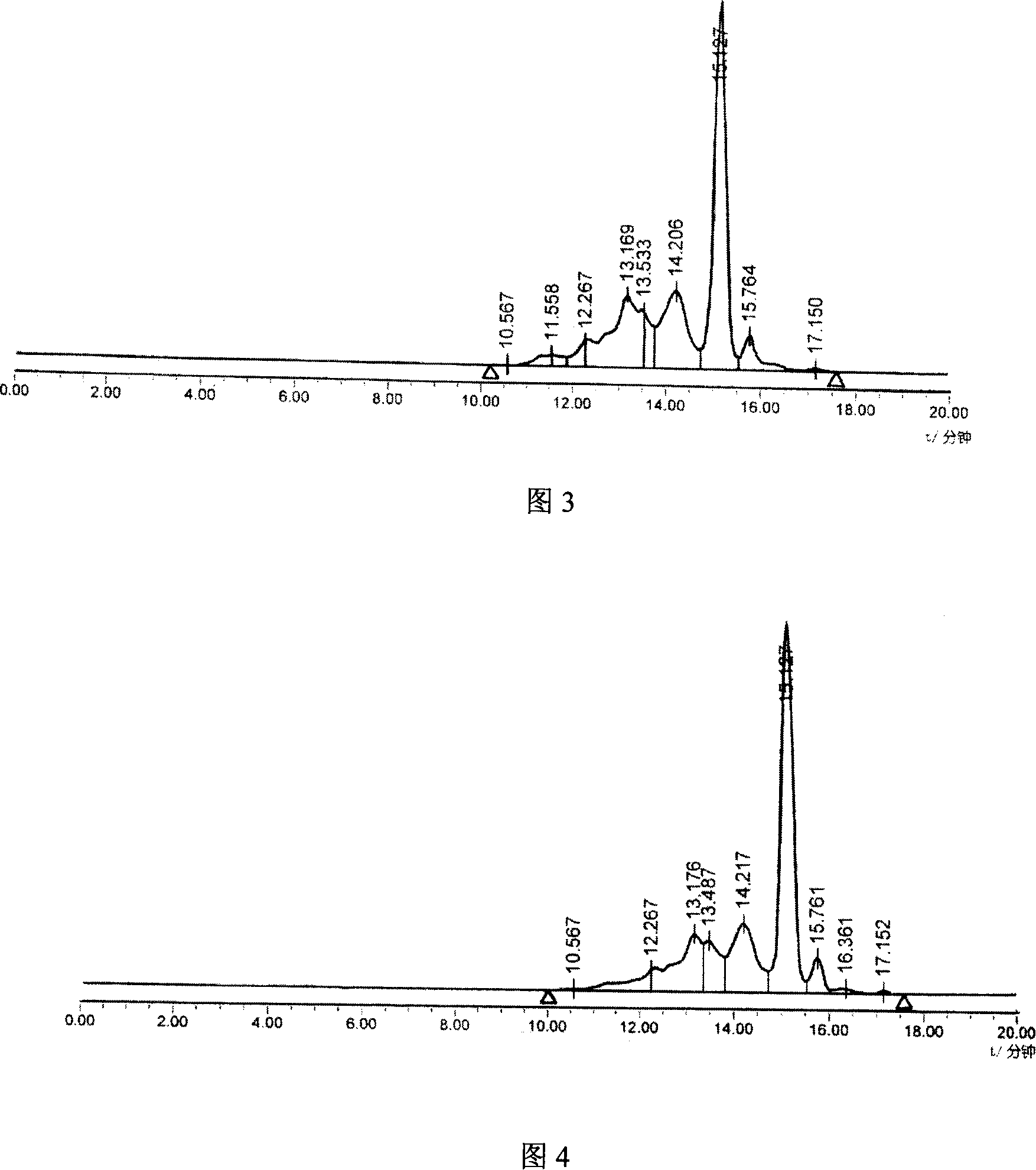

[0018] Respectively take ribonuclease A (molecular weight 13700), insulin (molecular weight 5800), thymosin α1 (molecular weight 3108), somatostatin (molecular weight 1638) as molecular weight standard solutions, high performance liquid chromatography, the obtained Products with a relative molecular weight of <2000D accounted for 92.49% of the total, and those between 2000D and 6000D accounted for 7.19%. See Figure 2 for the results.

Embodiment 3

[0020] Weigh 25g of royal jelly, add water to dissolve, adjust the pH to 9, control the substrate concentration to 2%, add trypsin equivalent to 2.5% of the substrate concentration, control the enzymolysis temperature at 55°C, and the enzymolysis time for 2 hours. Keep the solution homogeneous. After the reaction, the system was placed in a water bath at 85° C. for 20 minutes to inactivate the enzyme, and the obtained product was filtered and freeze-dried.

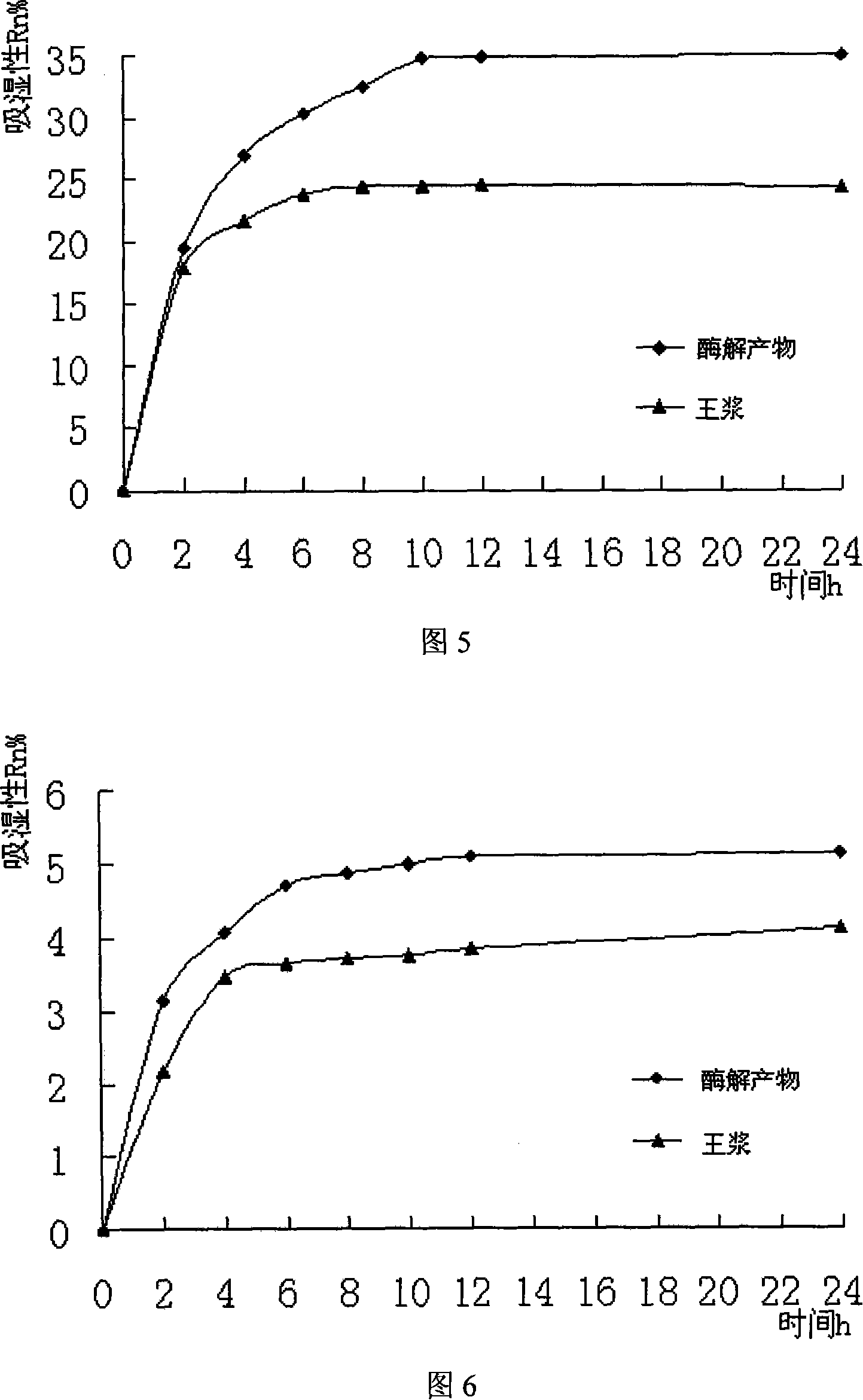

[0021] Respectively take ribonuclease A (molecular weight 13700), insulin (molecular weight 5800), thymosin α1 (molecular weight 3108), somatostatin (molecular weight 1638) as molecular weight standard solutions, high performance liquid chromatography, the obtained Products with a relative molecular weight <2000D accounted for 94.82% of the total, and products with a relative molecular weight of 2000D-6000D accounted for 5.15%. See Figure 3 for the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com