Method of producing three fundamental quantum dot CdZnSe

A technology of ternary quantum dots and stock solution, which is applied to the preparation field in the field of nanotechnology, can solve the problems of high price, limited large-scale preparation, higher than 290 ° C, etc., and achieves strong fluorescence performance, low preparation cost, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

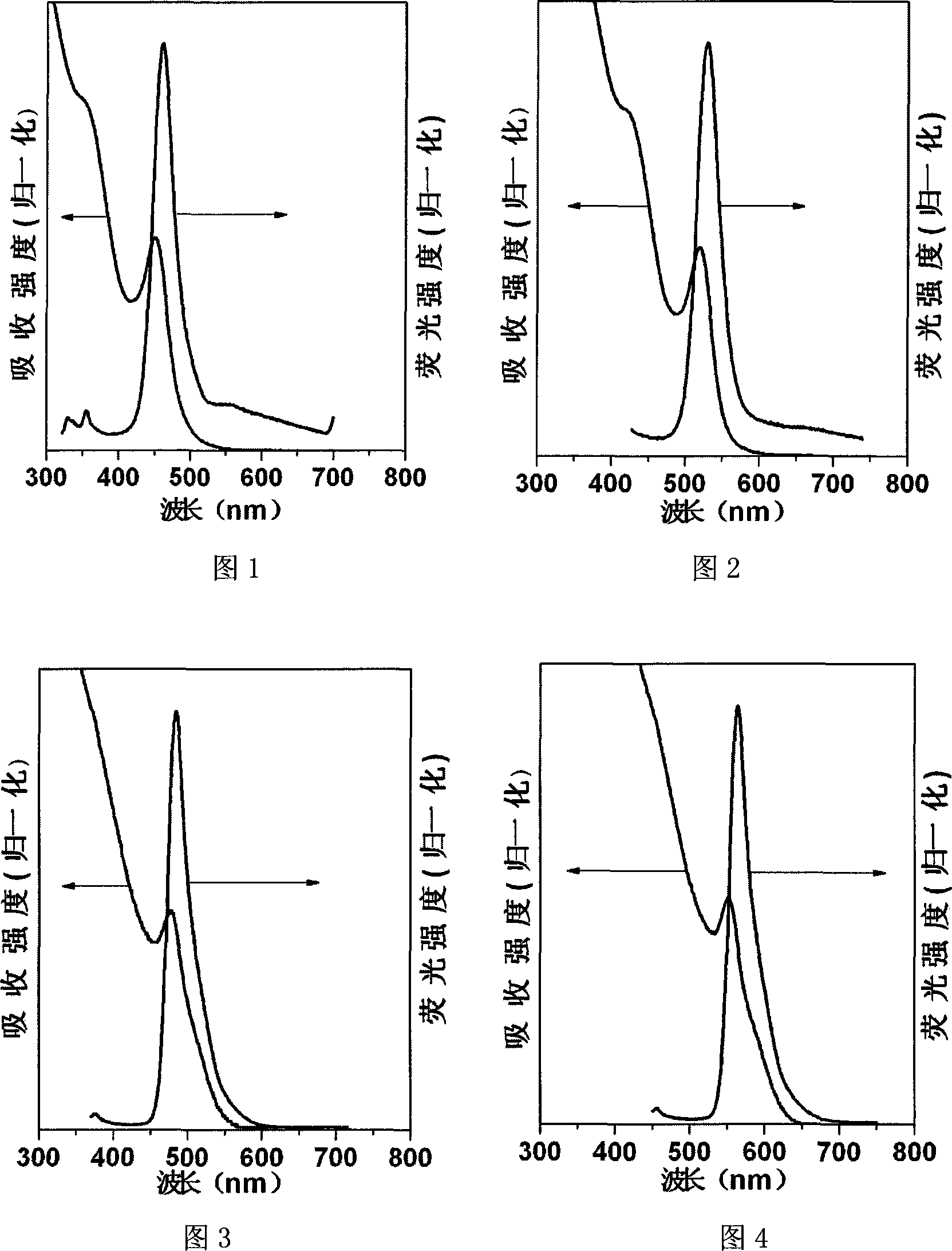

Image

Examples

Embodiment 1

[0020] (a) Weigh 0.065g (0.5mmol) CdO into a three-neck flask A, add 0.3mL (1mmol) oleic acid and 6mL liquid paraffin, heat to 150°C to completely dissolve CdO, and obtain a Cd precursor stock solution.

[0021] (b) Weigh 0.2g (0.32mmol) of zinc stearate into three-neck bottle B, add 2mL of TOP, and ultrasonically oscillate under nitrogen protection to completely dissolve zinc stearate to obtain a Zn precursor stock solution.

[0022] (c) Weigh 0.016g (0.2mmol) of Se powder and place it in a three-neck flask C, and add 19.5mL of liquid paraffin, 0.5mL of TOP and 0.06mL of oleylamine so that the molar ratio of Se to TOP is 1:5. The molar ratio of the amine was 1:1, and ultrasonic vibration was performed under the protection of nitrogen to completely dissolve Se to obtain a stock solution of Se precursor.

[0023] (d) Under nitrogen protection, the Se precursor stock solution was heated to 180 °C. 2mL of the Zn precursor solution and 1mL of the Cd precursor solution were quickl...

Embodiment 2

[0027] (a) Weigh 0.26g (2mmol) CdO into three-neck flask A, add 3.2mL (10mmol) oleic acid and 6.8mL liquid paraffin, heat to 150°C to completely dissolve CdO, and obtain a Cd precursor stock solution.

[0028] (b) Weigh 0.81g (1.28mmol) of zinc stearate into three-neck bottle B, add 2mL of TOP, and ultrasonically oscillate under nitrogen protection to completely dissolve zinc stearate to obtain a Zn precursor stock solution.

[0029] (c) Weigh 0.064g (0.8mol) of Se powder and place it in a three-neck flask C, and add 15.4mL of liquid paraffin, 4.5mL of TOP and 0.9mL of oleylamine so that the molar ratio of Se to TOP is 1:15. The molar ratio of the amine was 1:5, and ultrasonic vibration was performed under the protection of nitrogen to completely dissolve Se to obtain a stock solution of Se precursor.

[0030] (d) The stock solution of Se precursor was heated to 220 °C under nitrogen protection. 2mL Zn precursor solution and 1.6mL Cd precursor solution are quickly injected in...

Embodiment 3

[0034] (a) Weigh 0.26g (2mmol) CdO into a three-neck flask A, add 2mL (6mmol) oleic acid and 8mL liquid paraffin, heat to 150°C to completely dissolve CdO, and obtain a Cd precursor stock solution.

[0035] (b) Weigh 0.253g (0.4mmol) of zinc stearate into three-neck bottle B, add 2mL of TOP, and ultrasonically oscillate under nitrogen protection to completely dissolve zinc stearate to obtain a Zn precursor stock solution.

[0036] (c) Weigh 0.032g (0.4mmol) Se powder and place it in three-necked bottle C, and add 20mL liquid paraffin, 2mLTOP and 0.36mL oleylamine, make the molar ratio of Se and TOP be 1: 10, and the The molar ratio was 1:3, and ultrasonic vibration was performed under nitrogen protection to completely dissolve Se to obtain a stock solution of Se precursor.

[0037] (d) Under nitrogen protection, the Se precursor stock solution was heated to 200 °C. 2mL of the Zn precursor solution and 1mL of the Cd precursor solution are quickly injected into the high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com