Bunchiness hollow fiber film and method of preparing the same

A technology of external pressure hollow fibers and fiber membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Eliminate problems such as peeling damage, achieve high production efficiency and high bonding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

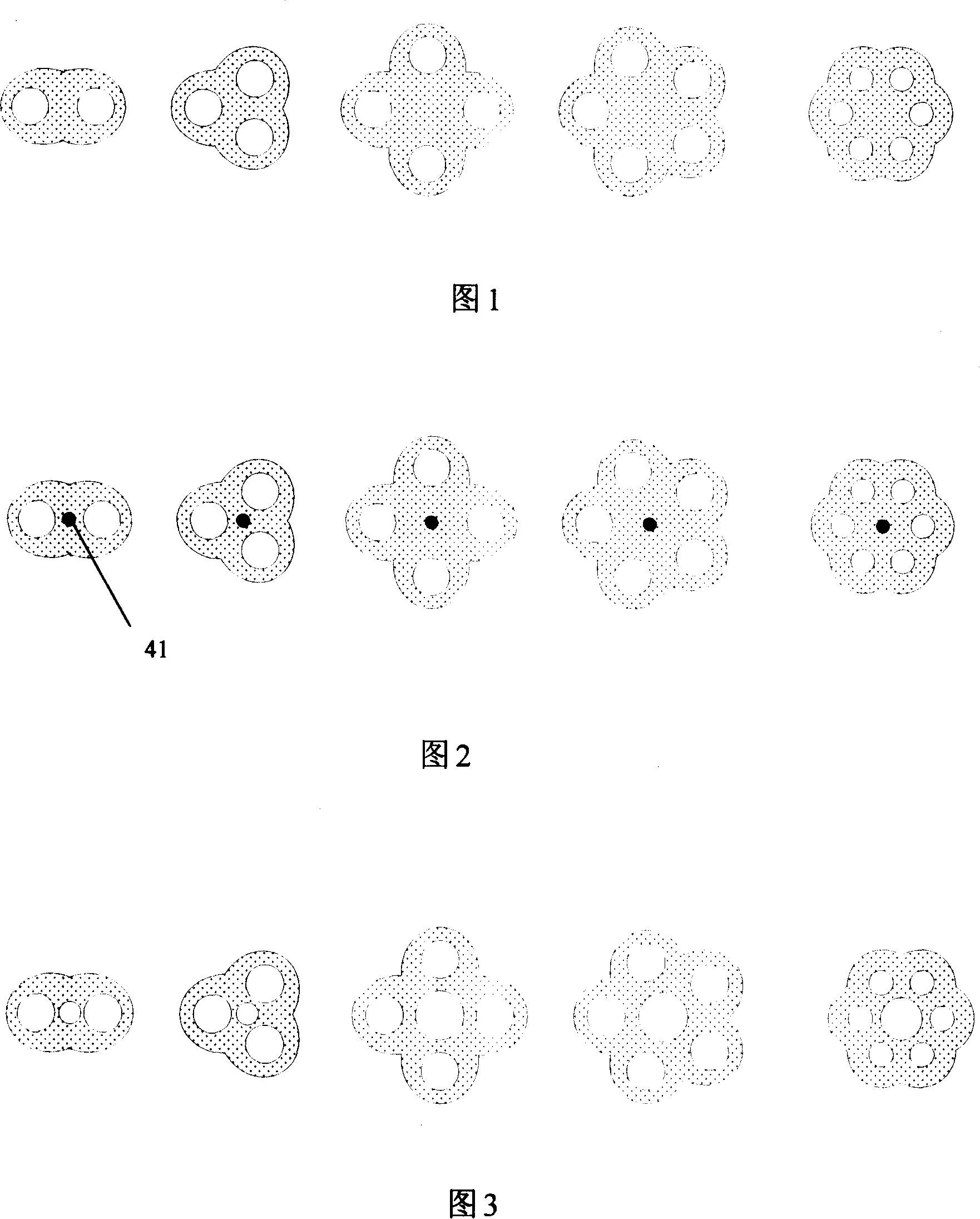

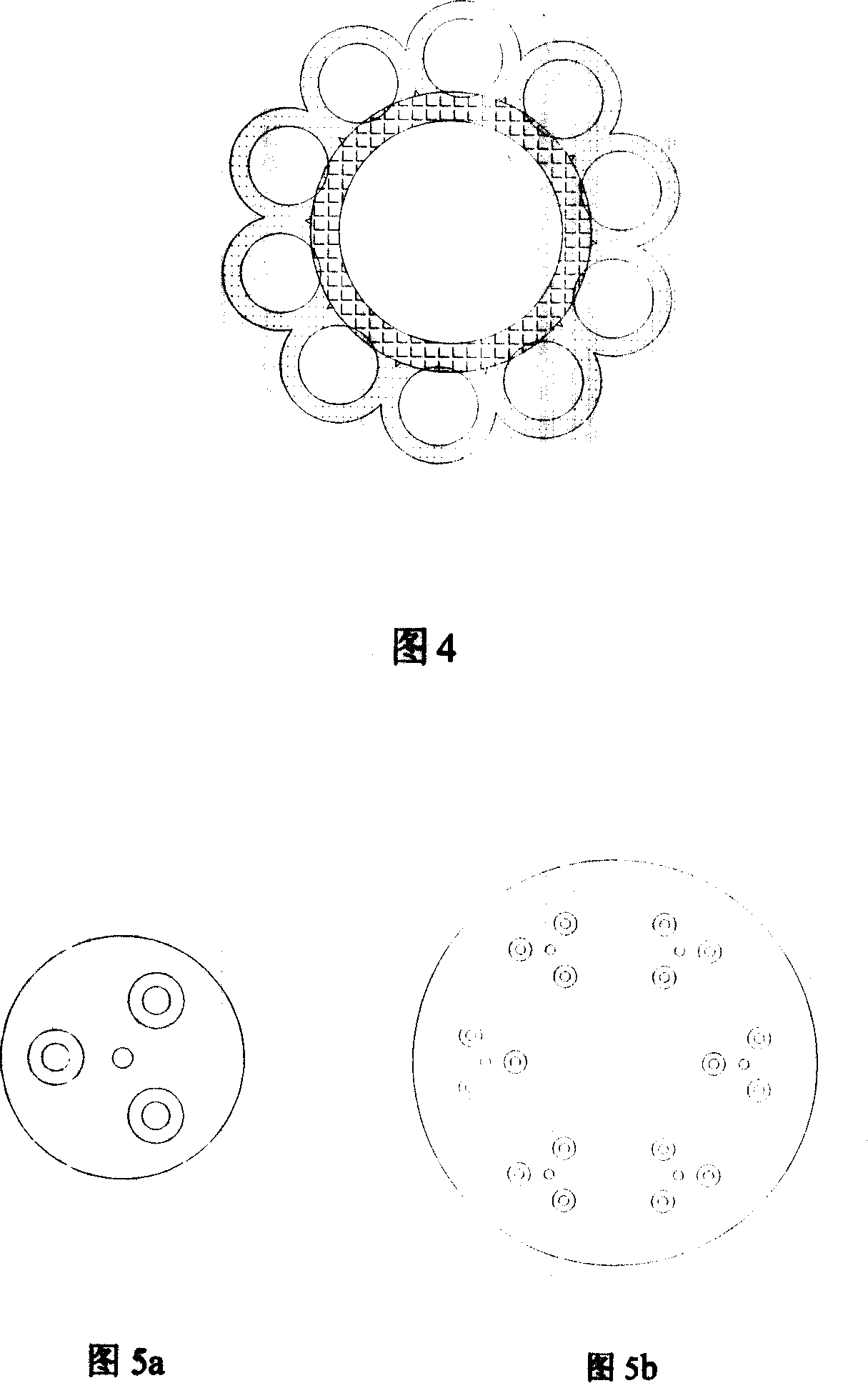

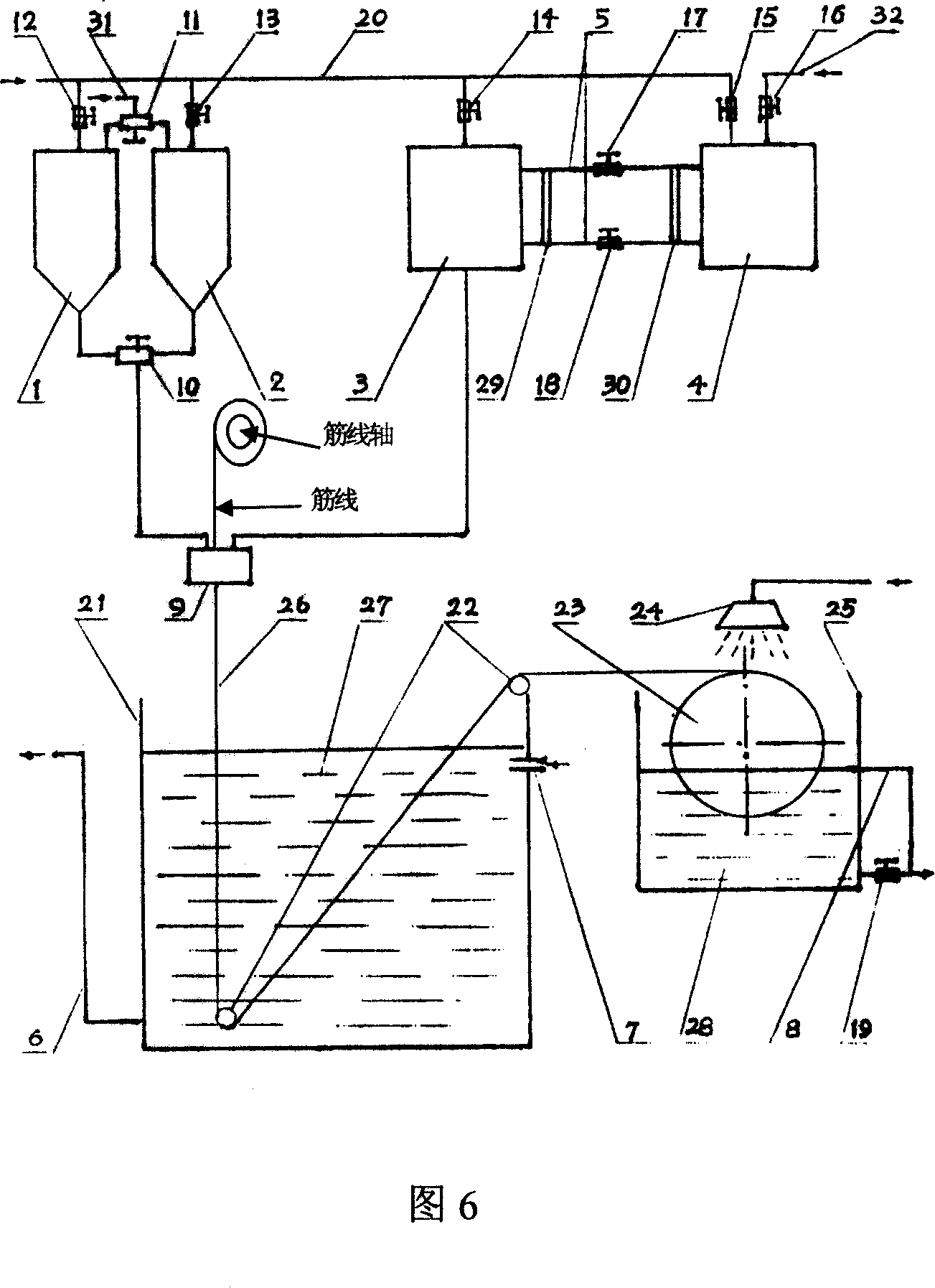

[0060] Embodiment 1: 500 grams of calcium carbonate 2 micron particles are stirred at high speed, uniformly dispersed in 5 kilograms of dimethylacetamide solvent, then add 2 kilograms of dimethylacetamide, 2 kilograms of polyvinylidene fluoride resin, 500 grams of polyvinylidene fluoride Ethylene glycol, 100 grams of Tween-20, stir and dissolve evenly, spin after defoaming. The above-mentioned spinning stock solution is passed through the three-strand six-strand nozzle as shown in Figure 5, and enters the coagulation bath together with the six polyester tendon threads to form a clustered hollow fiber membrane. The coagulant is water, the initial modulus of the polyester filament is 20-300cN / dtex, and the linear density of the polyester filament is 100--500dtex. The calcium carbonate in the polyvinylidene fluoride hollow fiber was removed with hydrochloric acid solution, and the obtained external pressure polyvinylidene fluoride hollow fiber porous membrane had an inner diamete...

Embodiment 2

[0062] Example 2: Under high-speed stirring of 500 grams of aluminum oxide 20-80 nanoparticles, uniformly disperse in 7 kilograms of N-methylpyrrolidone solvent, then add 2 kilograms of polyvinylidene fluoride resin, 500 grams of polyvinylpyrrolidone, 100 Gram Tween-80, stir to dissolve evenly, spin after defoaming. The above-mentioned spinning stock solution is put into the coagulation bath together with five strands of polypropylene ribs through the five-filament bundle and five-rib nozzle as shown in Figure 5 to form a clustered hollow fiber membrane. The polypropylene yarn density is 100--500dtex. The coagulant in the coagulation bath is water. The aluminum oxide in the polyvinylidene fluoride hollow fiber was removed by NaOH aqueous solution, and the obtained external pressure polyvinylidene fluoride hollow fiber porous membrane had an inner diameter of 0.6 mm, a wall thickness of 0.15 mm, and a single hollow fiber membrane bundle breaking tension of 11.7 kg. Pure water...

Embodiment 3

[0064] Embodiment 3: 800 grams of calcium carbonate 2 micron particles are stirred at high speed, uniformly dispersed in 5 kilograms of dimethylacetamide solvent, then add 1.8 kilograms of dimethylacetamide, 1.8 kilograms of polyvinylidene fluoride resin, 780 grams of polyvinylidene fluoride Vinylpyrrolidone and 20 grams of fluorosurfactant FC-4 are stirred and dissolved evenly, and spinning after defoaming. The coagulant in the coagulation bath is water. The six hollow fibers are bundled to obtain a bundled hollow fiber membrane. Remove the calcium carbonate in polyvinylidene fluoride hollow fiber with hydrochloric acid solution, and obtain the external pressure polyvinylidene fluoride hollow fiber porous membrane, with an inner diameter of 0.6mm, a wall thickness of 0.15mm, and a rupture strength of 0.43MPa. A single hollow fiber membrane bundle is broken Tension 1.7kg, pure water penetration rate 1210L / m 2 ·h@0.1MPa 20℃, membrane separation pore size 0.50μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com