Full-automatic injecting blowing plastic hollow molding machine control device and cybernation method thereof

A control device and fully automatic technology, which is applied in the direction of comprehensive factory control, comprehensive factory control, temperature control using electric methods, etc. It can solve the problems of simple man-machine interface, automatic adjustment of temperature control value, modification of PLC with programmer or portable computer procedures and other issues to achieve good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

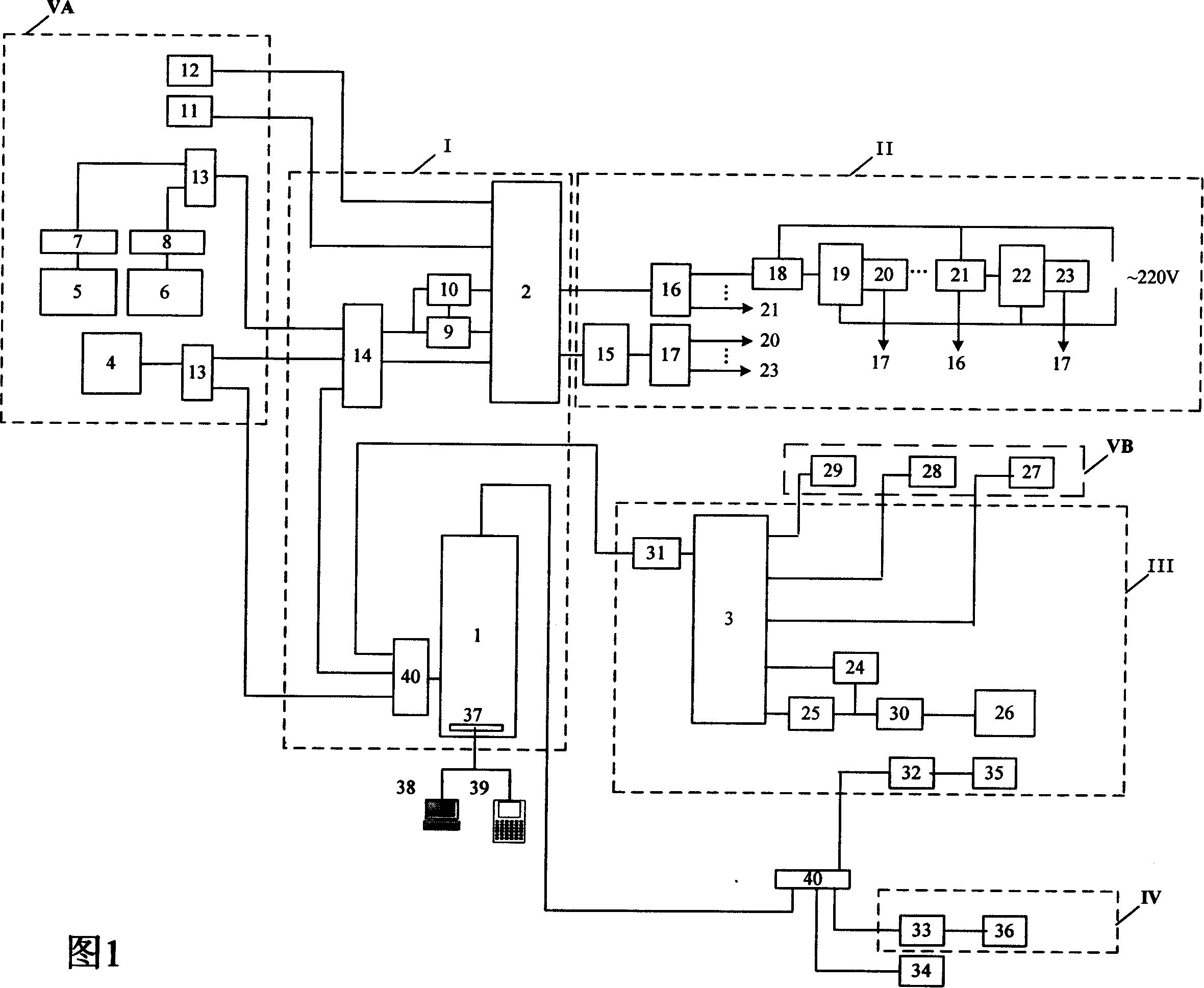

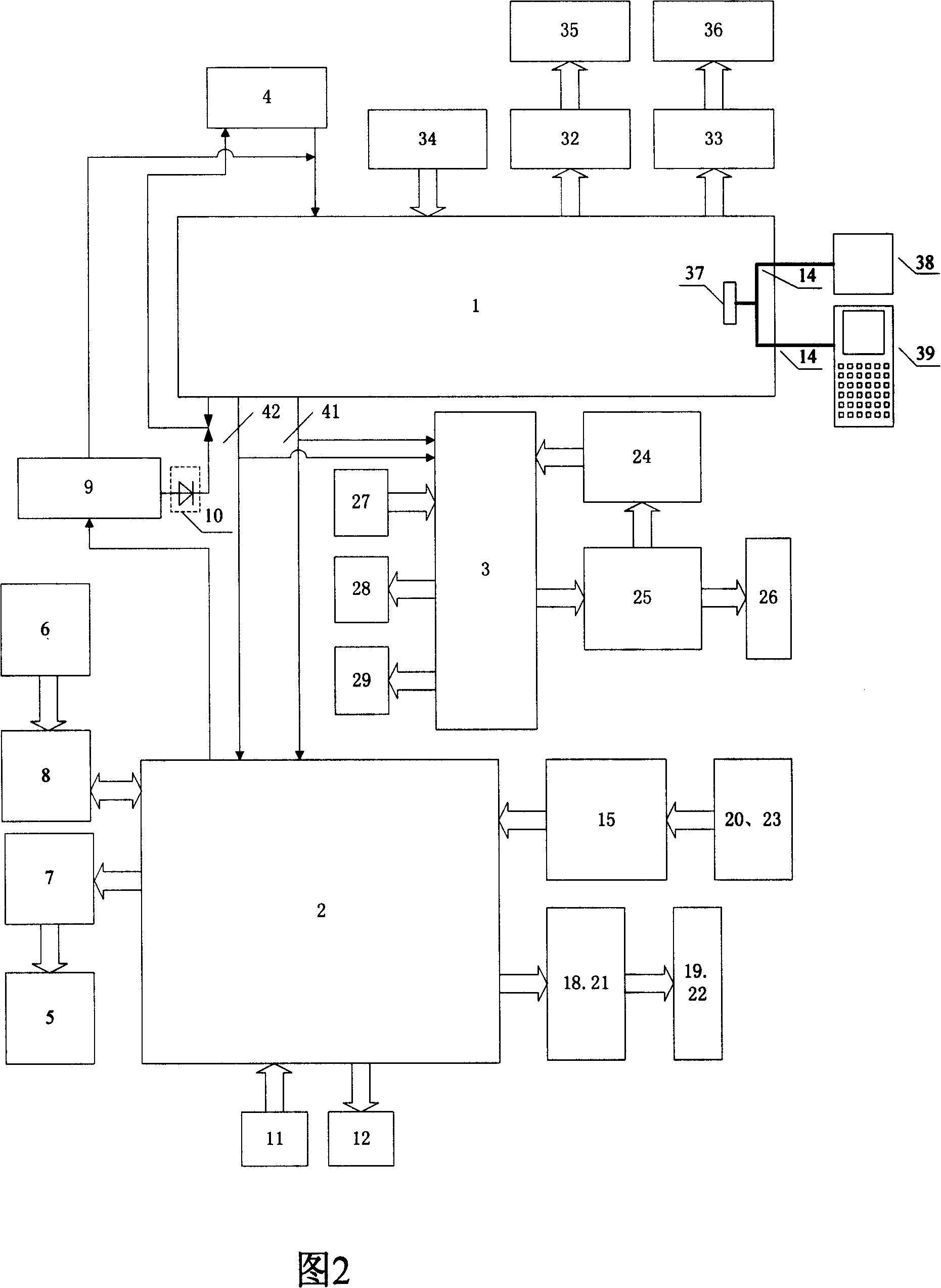

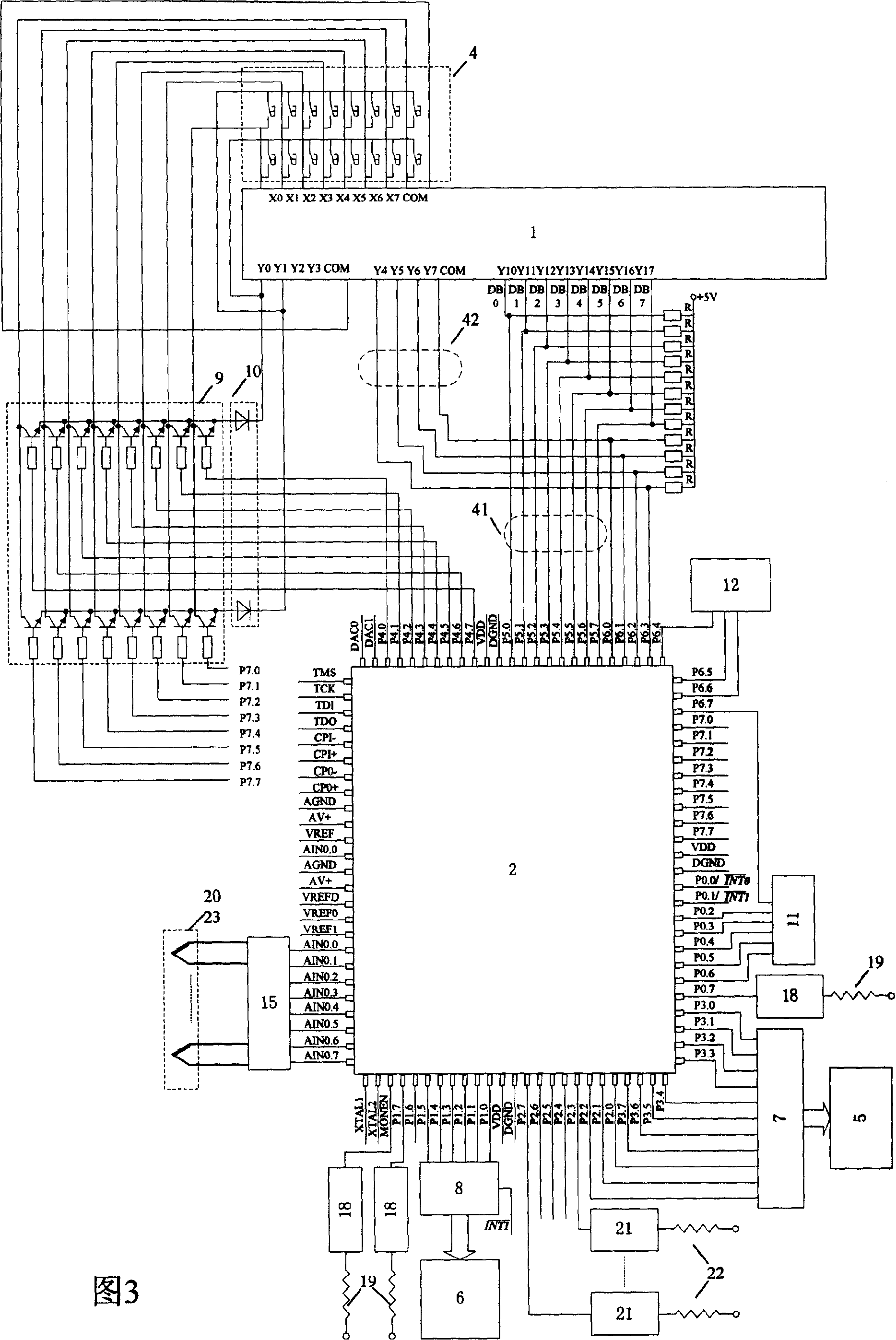

[0051] A fully automatic injection-blow plastic hollow molding machine control device, composed of PLC-high-speed single-chip microcomputer I, temperature control module II, hydraulic control system III, pneumatic control module IV and control panel V;

[0052] PLC-high-speed single-chip microcomputer system 1 is made up of PLC1, high-speed single-chip microcomputer 2, level conversion circuit 9 and current direction control circuit 10, and high-speed single-chip microcomputer 2 is through 8-bit data bus 41 and 4-bit address bus of terminal 14 and terminal 40 and PLC1 42 connection, the high-speed single-chip microcomputer 2 is also connected with the interconnected level conversion circuit 9 and the current direction control circuit 10 respectively, and the above-mentioned level conversion circuit 9 and the current direction control circuit 10 are connected with PLC1 through the connection terminal 14 and the connection terminal 40; PLC - The high-speed single-chip microcomput...

Embodiment 2

[0078] A method for automatically controlling the injection and blowing process of a fully automatic injection blow plastic hollow molding machine, the method is to use the present invention by PLC-high-speed single-chip computer system I, temperature control module II, hydraulic control system III, pneumatic control module IV and control The control device of the automatic injection-blow plastic hollow molding machine composed of panel V automatically controls the injection-blowing process of the automatic injection-blow plastic hollow molding machine, including: acquisition of system information, temperature control of the injection-blowing process, constant hydraulic flow rate of the electro-hydraulic proportional valve Flow control, mechanical motion control (including pneumatic control and single-bidirectional hydraulic valve control) and display monitoring; the steps (see Figure 9) are as follows:

[0079] Step 1: system initialization: the I / O port of high-speed single-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com