Halogen-free expansion fire retardant for polypropylene

An intumescent flame retardant, polypropylene technology, applied in the field of flame retardants for polyolefins, can solve the problems affecting the mechanical properties and prices of materials, processing difficulties, application restrictions, etc. The effect of less smoke generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

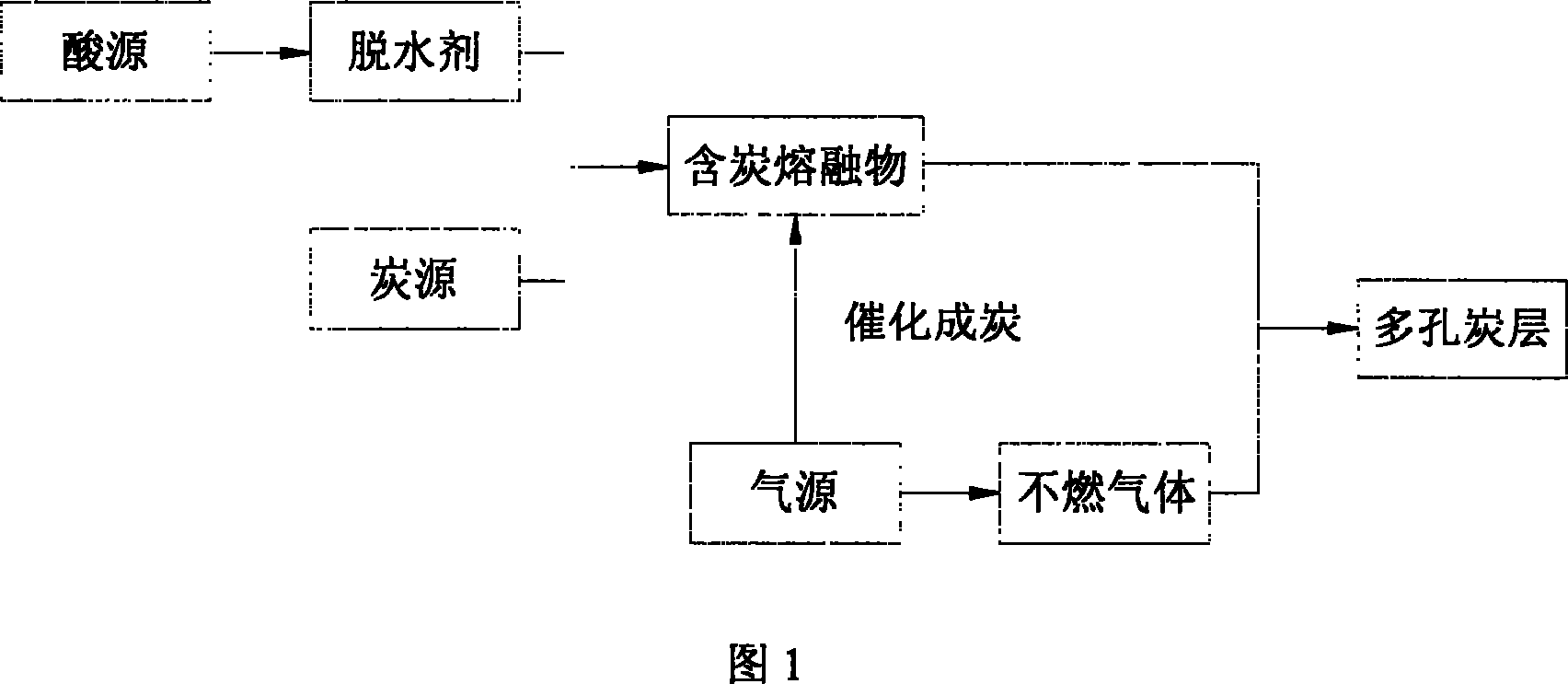

Method used

Image

Examples

Embodiment 1~26

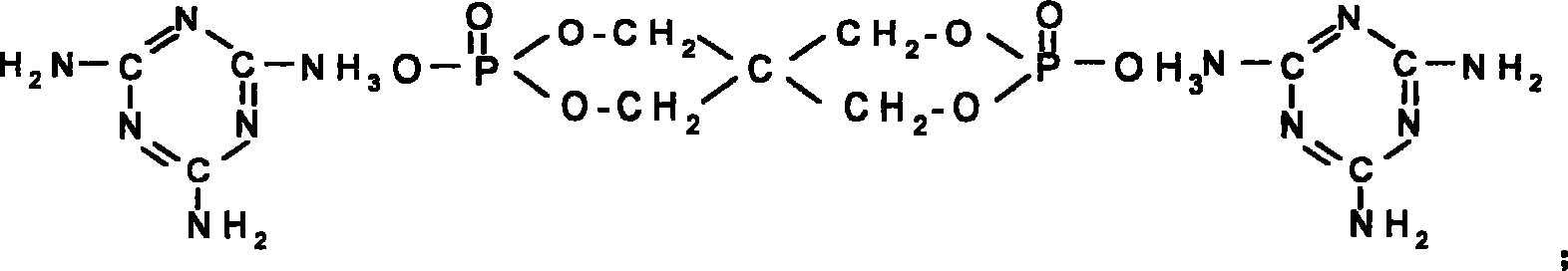

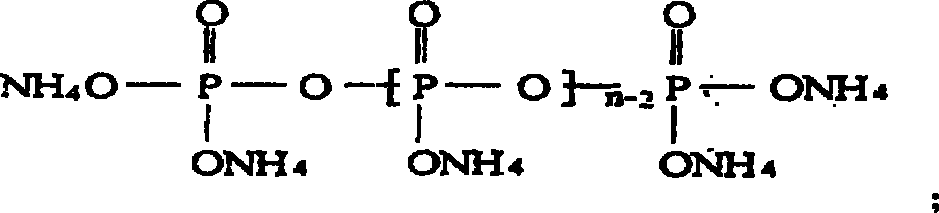

[0036] Examples are shown in Table 1. First, melamine melamine salt and ammonium polyphosphate are dried so that the water content is less than 0.2% (wt), and then pulverized so that the particle size is less than 35 μm.

[0037] Secondly, put the melamine melamine salt and ammonium polyphosphate, lubricant, coupling agent, and char-forming accelerator into the high-speed mixer and mix for 1-10 minutes with the composition shown in Table 1 to obtain halogen-free polypropylene Intumescent flame retardant.

[0038] Table 1 Proportion of halogen-free flame retardant for polypropylene

[0039] Real

[0040] 13

[0041] Table C 18 Stearic acid; C 18 Zn zinc stearate; C 18 Ca is calcium stearate; KH-550 is a product of γ-aminopropyl triethoxysilane; NDZ-101 is monoalkoxy titanate coupling agent; ZQ-560 is γ-glycidyl ether A product of oxypropyltrimethoxysilane; TiO 2 It is titanium dioxide; PA-6 is nylon 6.

[0042] Put the halogen-free flame retardant compounded w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com