Cathode material of zinc-nickel secondary batteries and preparation method thereof

A technology for secondary batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of zinc electrode deformation, affecting discharge capacity, and limited effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Take 8g ZnO, 1g SnCl 2 , 0.44g metal Zn powder and 0.088g nano-carbon fiber, the SnCl 2 Dissolve in concentrated HCl until completely dissolved, then dilute with deionized water to make SnCl 2 The concentration is 6.5g / L, add ZnO, fully stir, filter, wash, centrifuge to get Sn 6 o 4 (OH) 4 Surface modification ZnO, Sn 6 o 4 (OH) 4 The mass percent content is 10%, the Sn 6 o 4 (OH) 4 The surface modified ZnO is fully mixed with metal Zn powder and nano carbon fiber to obtain the negative electrode material of the zinc-nickel secondary battery. Add a small amount of PTFE, CMC and PVA to the uniformly mixed material as a binder, stir it with deionized water evenly, and then apply it to the collector foam nickel, after drying, pressing, and shearing, the size is: 20×20 ×0.4mm 3 , made of zinc electrodes.

Embodiment 2

[0014] Take 5g ZnO, 0.625g SnCl 2 , 0.55g metal Zn powder and 0.08g nano-carbon fiber, the SnCl 2 Dissolve in concentrated HCl until completely dissolved, then dilute with deionized water to make SnCl 2 The concentration is 6.5g / L; add ZnO, fully stir, filter, wash, and centrifuge to obtain Sn 6 o 4 (OH) 4 Surface modification ZnO, Sn 6 o 4 (OH) 4 The mass percent content is 10%, the Sn 6 o 4 (OH) 4 The surface modified ZnO is fully mixed with metal Zn powder and nano carbon fiber to obtain the negative electrode material of the zinc-nickel secondary battery. Add a small amount of PTFE, CMC and PVA to the uniformly mixed material as a binder, stir it with deionized water evenly, and then apply it to the collector foam nickel, after drying, pressing, and shearing, the size is: 20×20 ×0.4mm 3 , made of zinc electrodes.

Embodiment 3

[0016] Take 10g ZnO, 1.25g SnCl 2 , 1.65g metal Zn powder and 0.11g nano-carbon fiber, the SnCl 2 Dissolve in concentrated HCl until completely dissolved, then dilute with deionized water to make SnCl 2 The concentration is 6.5g / L; add ZnO, fully stir, filter, wash, and centrifuge to obtain Sn 6 o 4 (OH) 4 Surface modification ZnO, Sn 6 o 4 (OH) 4 The mass percent content is 10%, the Sn 6 o 4 (OH) 4 The surface modified ZnO is fully mixed with metal Zn powder and nano carbon fiber to obtain the negative electrode material of the zinc-nickel secondary battery. Add a small amount of PTFE, CMC and PVA to the uniformly mixed material as a binder, stir it with deionized water evenly, and then apply it to the collector foam nickel, after drying, pressing, and shearing, the size is: 20×20 ×0.4mm 3 , made of zinc electrodes.

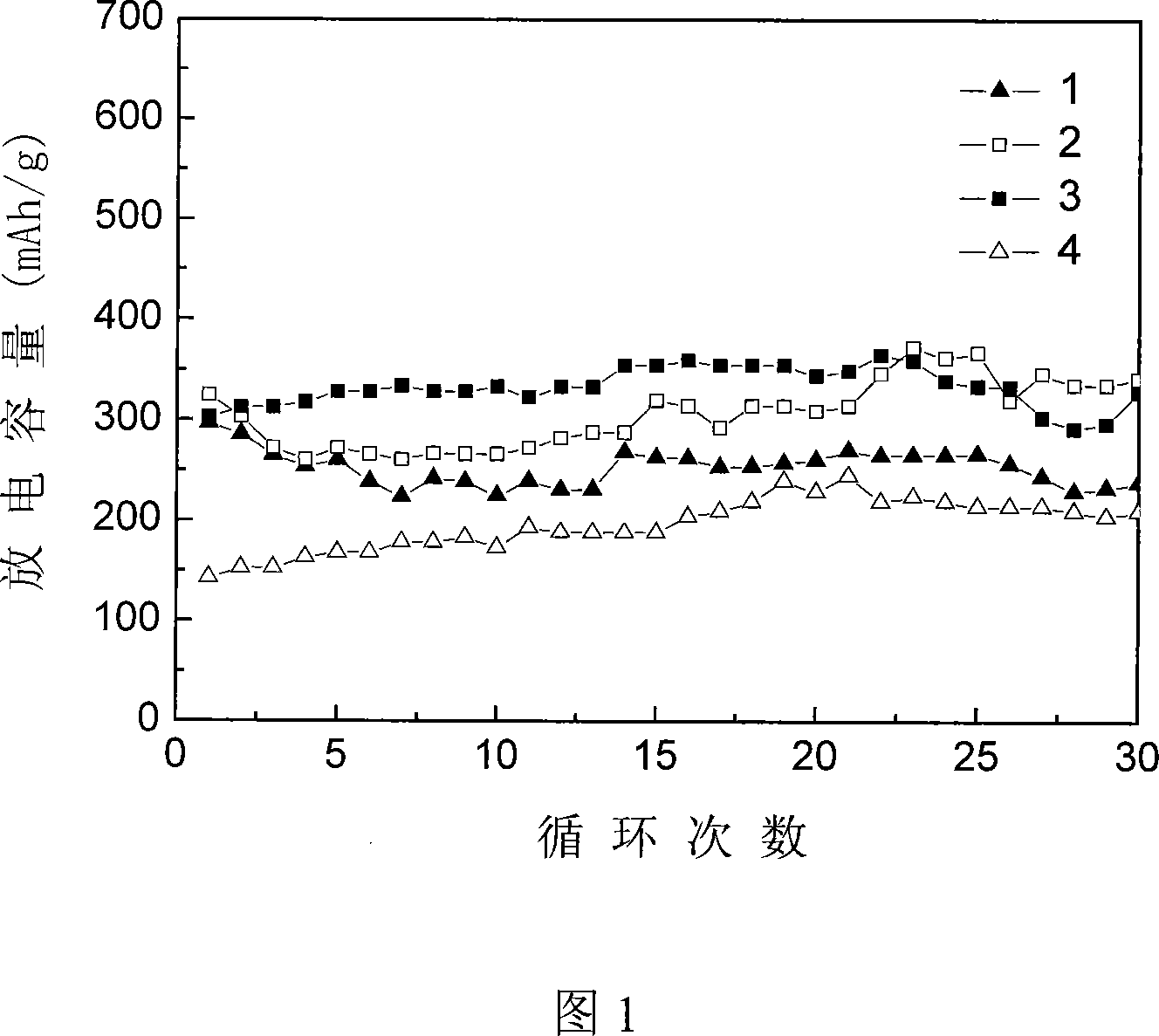

[0017] The positive electrode of all embodiments is the β-Ni(OH) that is pasted and pressed on foamed nickel 2 Electrodes, the capacity of the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com