Method for synthesizing polymer chelating agent with polyvinyl alcohol as base chain

A polymer chelating agent, polyvinyl alcohol technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as inconvenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

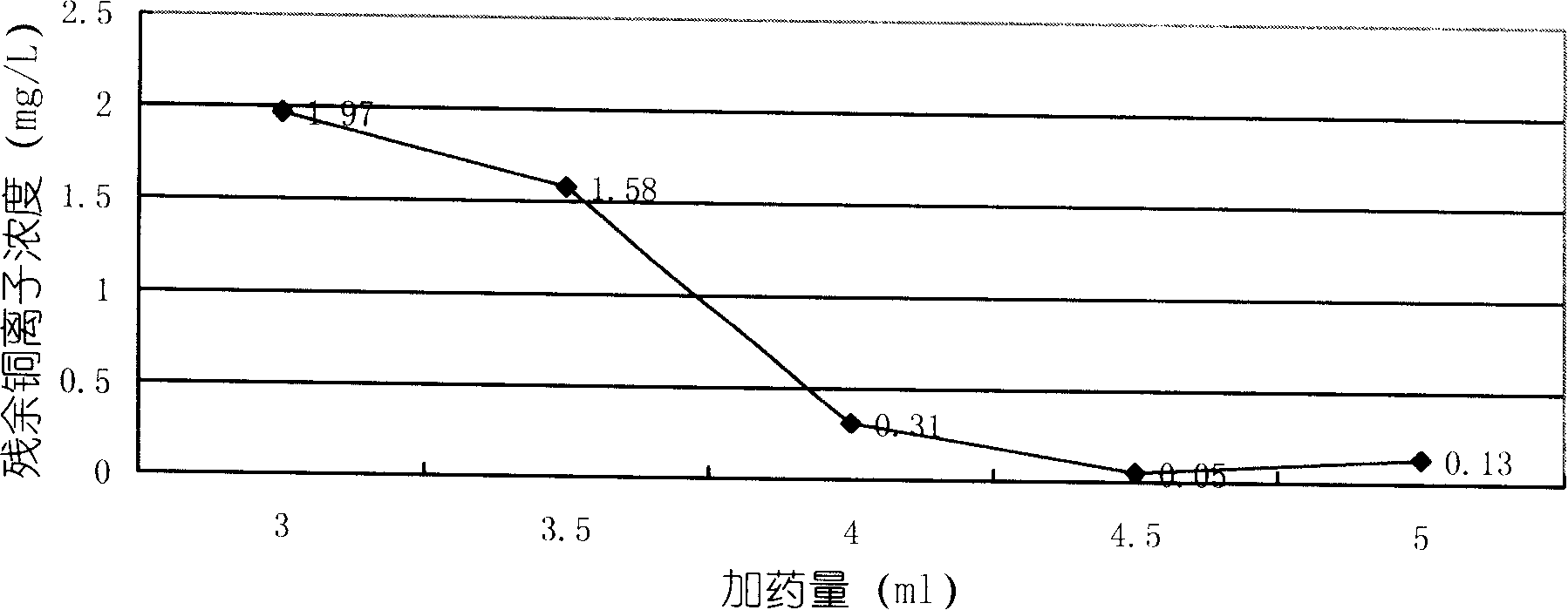

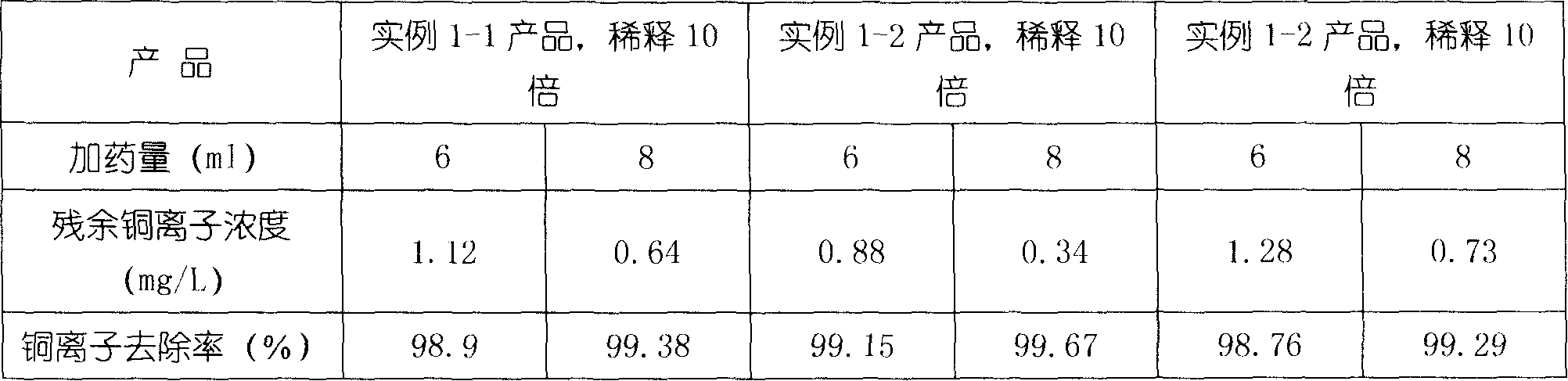

[0023] (1) Synthesize three parts of polymer chelating agent according to the three groups of different raw material ratios in "Table 1" as follows: add the prepared sulfuric acid solution into the reaction kettle, start the agitator, slowly add polyvinyl alcohol, and stir Until the polyvinyl alcohol is completely dissolved; slowly add the etherification agent (epichlorohydrin), control the reaction temperature at 30°C, and continue stirring for 2 hours after the addition; then slowly add diethylenetriamine to the reactor, and use cooling water to control the reaction The temperature does not exceed 80°C, and continue to stir for 1 hour after the addition; add the dissolved sodium hydroxide solution cooled to room temperature into the reaction kettle, and stir for 0.5 hours; then slowly add the chain extender (epichlorohydrin) dropwise, and control The reaction temperature does not exceed 80°C, continue to stir for 2 hours after the addition; then slowly add carbon disulfide dr...

Embodiment 2

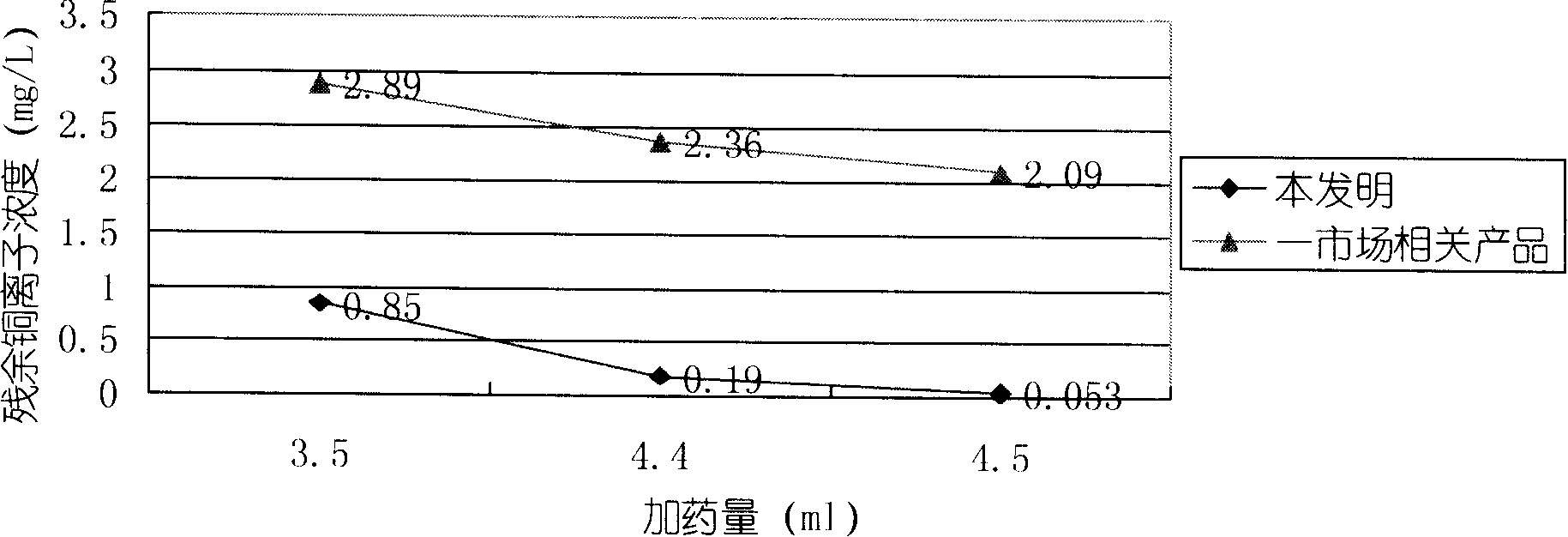

[0031] Add 27g of 20% sulfuric acid solution into the reaction kettle, start the agitator, add 1.74g of polyvinyl alcohol (polymerization degree 1700), stir until the polyvinyl alcohol is completely dissolved; slowly add 5.85g of epichlorohydrin, and control the reaction temperature below 30°C , continue to stir for 1 hour after the addition; then slowly add 38.4g of diethylenetriamine to the reactor, use cooling water to control the reaction temperature not to exceed 80°C, continue to stir for 2 hours after the addition; dissolve 58g of sodium hydroxide in 82.3g In distilled water, add it into the reaction kettle after cooling, and stir for 0.5 hours; then slowly add 10 g of chain extender epichlorohydrin, and use cooling water to control the reaction temperature not to exceed 80°C, and continue stirring for 1 hour after adding; then slowly drop Add 76.8g of carbon disulfide, control the reaction temperature with cooling water to be 30° C., continue to stir and react for 4 hou...

Embodiment 3

[0034] Add 27g of 20% sulfuric acid solution into the reaction kettle, start the agitator, add 1.74g of polyvinyl alcohol (polymerization degree 500), stir until the polyvinyl alcohol is completely dissolved; slowly add 5.85g of epichlorohydrin, and control the reaction temperature below 30°C , continue to stir for 1 hour after the addition; then slowly add 38.4g of diethylenetriamine to the reactor, use cooling water to control the reaction temperature not to exceed 80°C, continue to stir for 2 hours after the addition; dissolve 58g of sodium hydroxide in 82.3g In distilled water, add it into the reaction kettle after cooling, and stir for 0.5 hours; then slowly add 20 g of chain extender epichlorohydrin, and use cooling water to control the reaction temperature not to exceed 80°C, and continue stirring for 1 hour after adding; then slowly drop Add 76.8g of carbon disulfide, control the reaction temperature with cooling water to be 30° C., continue to stir and react for 4 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com