Interferometer and method of use thereof

An interferometer and micro-moving platform technology, applied in the field of interferometers, can solve the problems of large volume adjustment of interferometers, complicated manufacturing and installation, and difficulty in wave aberration detection, and achieve convenient movement, reduce volume, increase reliability and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

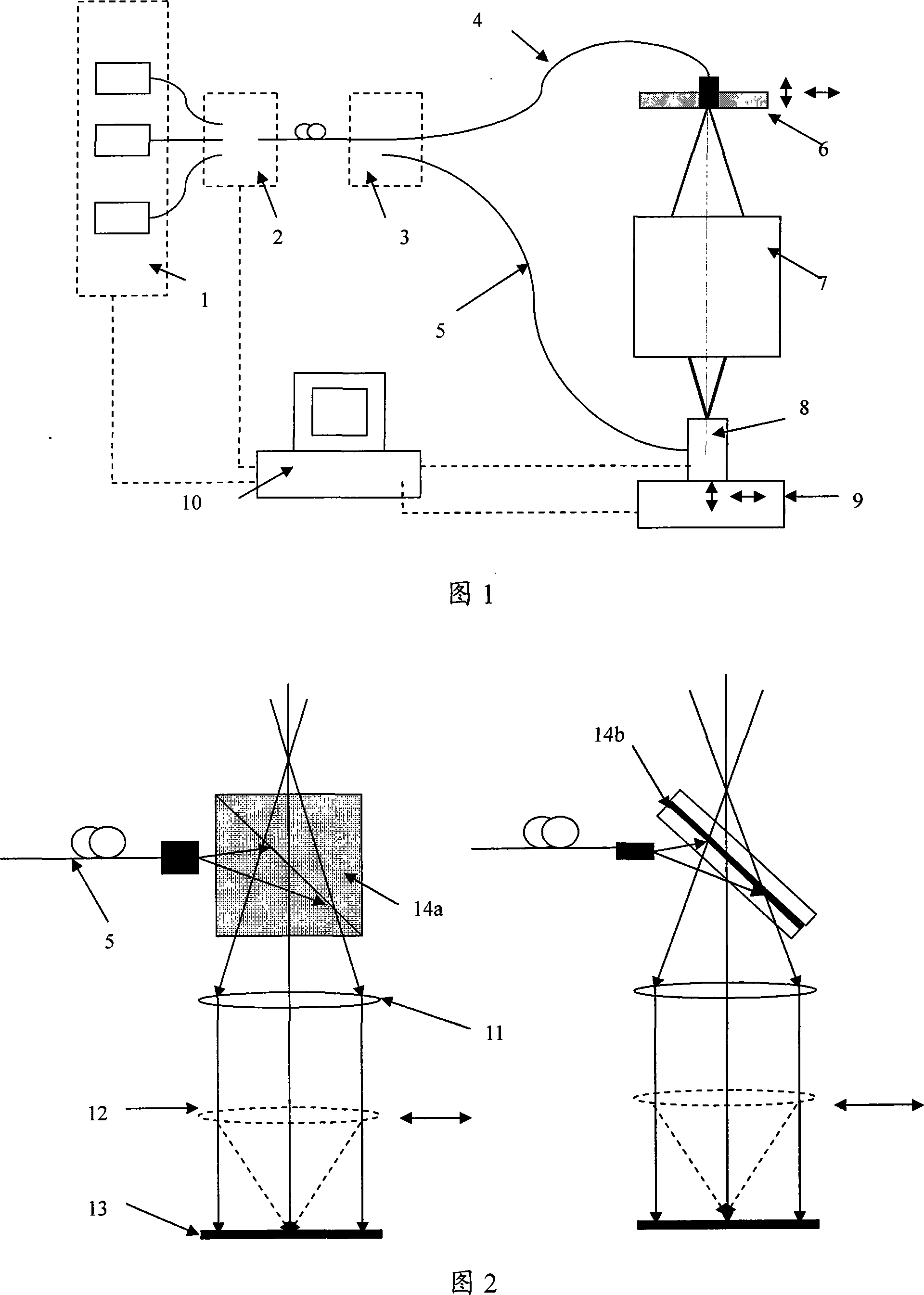

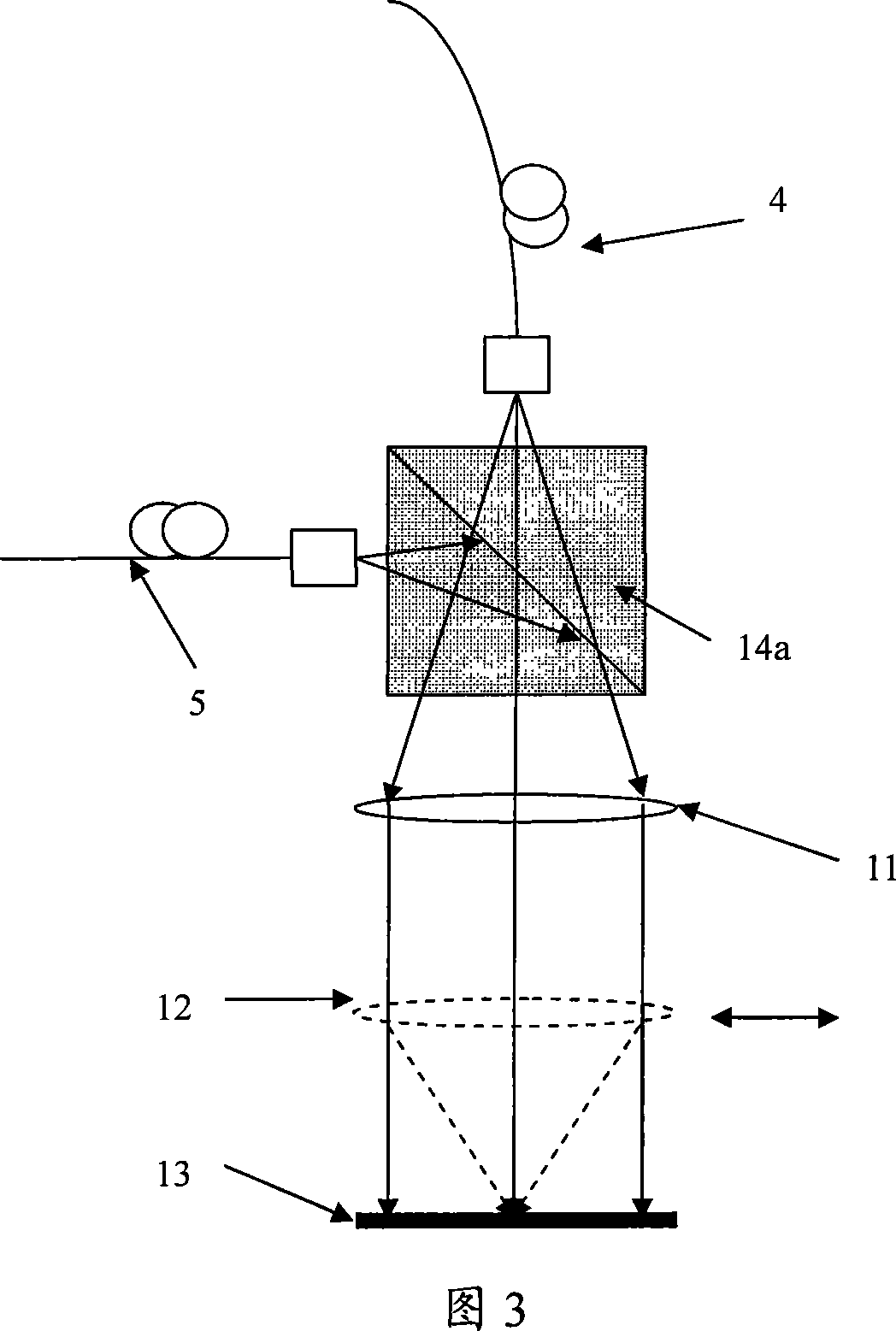

[0032] The interferometer of the present invention uses an optical fiber as a transmission optical path to generate a standard wavefront, and adopts a common path interference system to realize the aberration detection of the projection objective lens of the encapsulated lithography machine. The specific device is as follows:

[0033] First, please refer to Figure 1. Figure 1 is a schematic diagram of the structure of the interferometer of the present invention. The laser light source module 1 contains three semiconductor lasers with wavelengths of 375nm, 405nm and 436nm. These three wavelengths basically cover the working bandwidth of the objective lens under test. Each semiconductor laser is coupled to a single-mode fiber for output. In order to obtain a standard diffracted wavefront, the single-mode fiber chooses a smaller core size; the optical switch 2 is connected to the laser light source module 1 through a single-mode fiber; After switch 2 is splitter module 3, splitter mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com