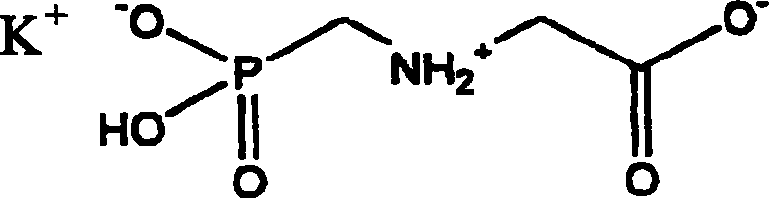

Method for preparing solid glyphosate potassium salt

A technology of glyphosate potassium salt and glyphosate acid is applied in the field of preparation of herbicide solids, which can solve the problems of increased crystallization difficulty, high solubility and high energy consumption, and achieves reduction of drying heat load, the method is simple and feasible, The effect of resistance to rain erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add water 100g and glyphosate acid wet product 100g (dry product purity 95%, water content 8%) in the reaction that has stirring and cooling device wherein, stir to form the suspension containing glyphosate; With 35g potassium hydroxide Dissolve in 100g of water to form lye; gradually add lye dropwise to the glyphosate suspension under stirring to make it react, a large amount of heat is generated during the reaction, and the temperature of the reaction mixture rises gradually from 20°C to 75°C. At the same time, the reaction system gradually changed from a white suspension system to a colorless and transparent solution. After the dropwise addition, it was cooled and gradually precipitated from crystals. When cooled to room temperature, it was separated by filtration to obtain 44.8 g of glyphosate potassium salt wet product and 290.2 g of mother liquor. After drying the wet product of potassium salt of glyphosate, 41.2 g of the original drug of potassium salt of glypho...

Embodiment 2

[0041] Add 100g water and 120g glyphosate acid former powder dry product (purity 95%) at one time in the 1L reaction kettle that has stirrer, thermometer, add the glyphosate acid that molar number is converted into 100% purity under stirring state 1.1 times the 50% potassium hydroxide solution for reaction, the reaction temperature is controlled at 30-90°C, after 1.5 hours of reaction, the feed liquid is clear, the highest temperature is 68°C, the solid-liquid mixture obtained by cooling and concentrating, and filtering to obtain glyphosate Potassium salt crystals 86.5g. The content of glyphosate potassium salt was analyzed to be 98.2wt% (calculated as glyphosate potassium salt). The filtered mother liquor can be used to prepare 41% glyphosate potassium saline solution.

Embodiment 3

[0043] In the 1L reactor with agitator and thermometer, add the mother liquor 330g and 120g glyphosate acid dry product (purity 95%) of embodiment 2 gained mother liquor at one time, add molar number under stirring state and be equivalent to 100% purity Glyphosate acid 1.1 times the 50wt% potassium hydroxide solution for reaction, the reaction temperature is controlled at 30 ~ 90 ° C, after 1.5 hours of reaction, the feed liquid is clear, the highest temperature is 71 ° C, the solid-liquid mixture obtained by cooling and concentrating, filtering 130.8 g of glyphosate potassium salt crystals were obtained. The content of glyphosate potassium salt was analyzed to be 97.5wt% (calculated as glyphosate potassium salt). The filtered mother liquor can be used to prepare 41% glyphosate potassium saline solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com