Gene engineering bacterium for catalyzing citral to produce citronellal and construction method thereof

A technology of genetically engineered bacteria and construction methods, applied in the field of genetically engineered bacteria that biocatalyze citral to generate citronellal and its construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 , Construction of genetically engineered bacteria

[0034] 1.1. Primer design

[0035] According to the sequence of the NADH oxidase gene gye in NCBI Genbank, the PCR primers Pgye-1 and Pgye-2 sequences for amplifying the gye gene were designed as follows:

[0036] Pgye-1: 5'-CGAC ATATG CCAACCCTGTTCGATC-3';

[0037] Pgye-2: 5'-TTAG AATTC TCAGTTGGGGCCGGAGGTG-3'.

[0038] In order to facilitate enzyme digestion and connection with the expression vector, an Nde I restriction site was introduced into the primer Pgye-1, and an EcoR I restriction site was introduced into the primer Pgye-2. The restriction sites are respectively underlined in the sequences.

[0039] 1.2. Cloning of gene gye

[0040] The total DNA of Gluconobacter oxidans (DSM2003) was obtained with a bacterial DNA extraction kit, and the gdh gene was amplified by PCR using it as a template and Pgye-1 and Pgye-2 as primers. The specific conditions were as follows:

[0041] Reaction system: 1 ...

Embodiment 2

[0050] Example 2 , Genetic engineering bacteria fermentation expression and product detection

[0051] 2.1. Fermentative expression and purification of genetically engineered bacteria BL21 / gye

[0052] The genetically engineered bacteria BL21 / gye obtained in Example 1 was inoculated into LB medium, cultivated to the logarithmic growth phase at 37° C., added IPTG to a final concentration of 1 mmol / L, and continued to cultivate for 6 hours.

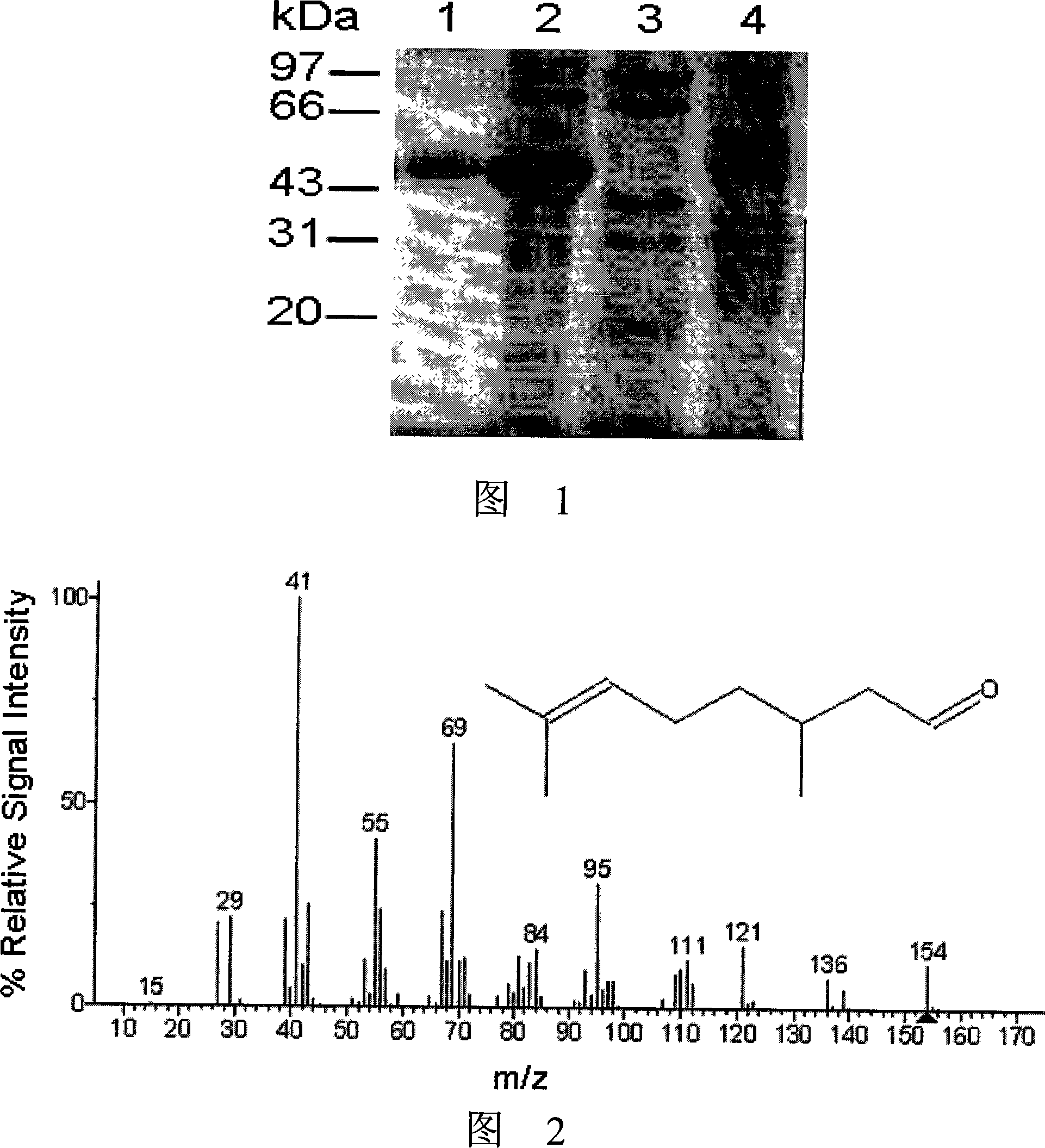

[0053] Bacteria were collected by centrifugation, and the bacteria were broken by ultrasonication. The supernatant was collected by centrifugation and purified with a His-Tag affinity column. The obtained purified product was subjected to SDS-PAGE electrophoresis. It is expected that the band size of NADH oxidase is consistent, which proves that the constructed genetically engineered strain BL21 / gye can ferment and express NADH oxidase.

[0054] 2.2. Detection of fermentation products

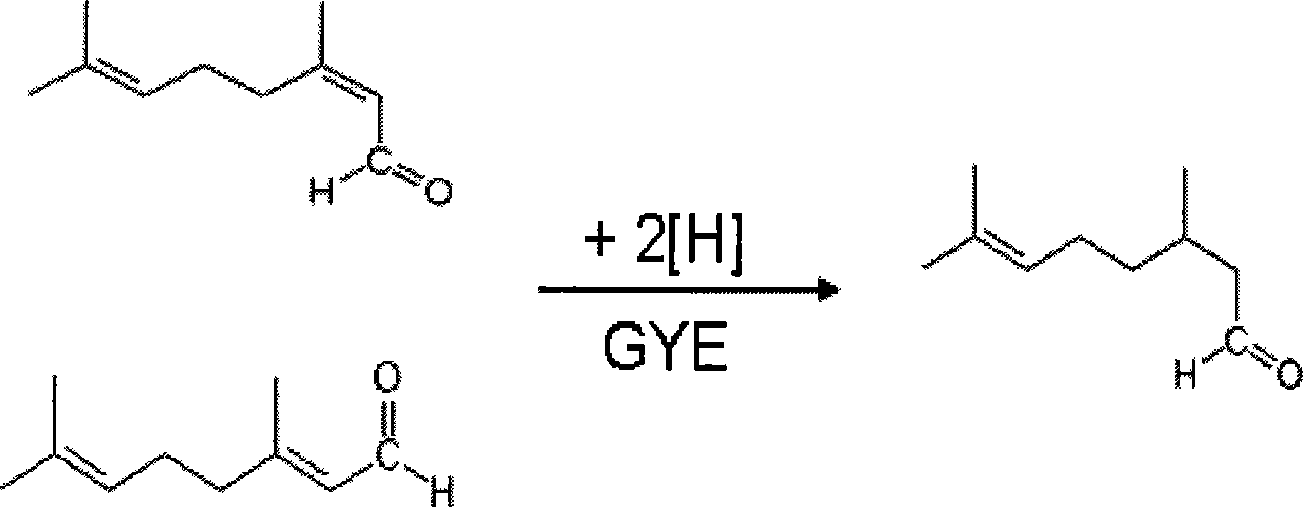

[0055]Add the purified NADH oxidase protein obtain...

Embodiment 3

[0056] Example 3 , Production of citronellal by genetically engineered bacteria BL21 / gye

[0057] The strain used in this example is the genetically engineered bacterium BL21 / gye obtained in Example 1.

[0058] The medium formula used in this example is: peptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, kanamycin 0.05g / L, pH 7.0.

[0059] Insert the genetically engineered bacteria BL21 / gye into a 500mL shake flask filled with 200mL medium, culture at 37°C and 250rpm, and take samples regularly to detect OD 650 value, when OD 650 When it is 0.4, add IPTG to a final concentration of 1 mmol / L, and induce culture for 14 hours.

[0060] Add citral to the shake flask to a final concentration of 10% by weight and volume, add acetonitrile to a final concentration of 10% by weight to volume, and react at 35° C. and 250 rpm for 4 hours.

[0061] Get reaction solution, obtain citronellal with chloroform extraction separation and purification, measure and adopt gas chromatogr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com