Dye-sensitized photoelectric conversion device

A photoelectric and component technology, applied in the field of pigment-sensitized photoelectric conversion elements, can solve the problems of low durability, high pigment cost, and has not yet reached practical application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0181] 1 part of methyl cyanoacetate and 2 parts of the following compound (318) were dissolved in 20 parts of ethanol. 0.01 part of piperidine was added to this solution, and it heated and refluxed for 2 hours. After the reaction, the solution was cooled, and the precipitated crystals were separated and purified by column chromatography, and recrystallized from ethanol to obtain 2.1 parts of orange crystals. The orange crystals were refluxed in 20 parts of ethanol in the presence of 1 part of potassium hydroxide for 2 hours. Add 50 parts of water to the reaction solution, neutralize with hydrochloric acid, filter the precipitated orange crystals, wash with water, and recrystallize with ethanol to obtain 1.2 parts of orange-brown crystals of compound number (32a).

[0182]

[0183] The maximum absorption wavelength of this compound and the measured value in a nuclear magnetic resonance apparatus are shown below.

[0184] Maximum absorption wavelength: λmax=448nm (water: a...

Embodiment 2

[0188] Except changing 2 parts of the above-mentioned compound (318) into 2 parts of the following compound (319), the same treatment as in Example 1 was carried out to obtain 1.4 parts of orange-brown crystals of compound number (278).

[0189]

[0190] The maximum absorption wavelength of this compound and the measured value in a nuclear magnetic resonance apparatus are shown below.

[0191] Maximum absorption wavelength: λmax=395nm (water: acetonitrile=7:3)

[0192] NMR measurements:

[0193] 1H-NMR (PPM:d6-DMSO): 1.34(t.3H), 4.50(m.2H), 7.28(m.2H), 7.52(m.1H), 7.69(t.2H), 7.84(m. 2H), 8.14(d.1H), 8.31(d.1H), 8.62(d.1H)

Embodiment 3 to 9

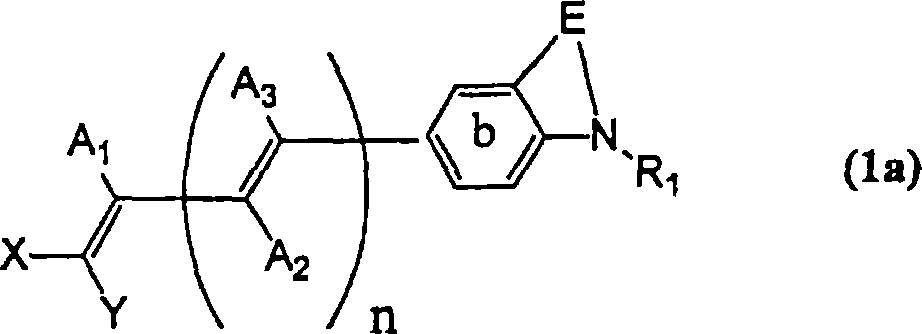

[0195] The methine pigment of the compound number shown in Table 7 was dissolved in ethanol (EtOH), making it 3.2×10 -4 M. Immerse the porous substrate (semiconductor thin film electrode formed by sintering porous titanium oxide on a transparent conductive glass electrode at 450°C for 30 minutes) in the solution for 12 hours at room temperature (20°C) to load each pigment, and then add the solvent (Ethanol) was washed and dried to obtain a photoelectric conversion element of the present invention including a dye-sensitized semiconductor thin film. For Example 8 and Example 9, two kinds of dyes were used (the methine-based dye of the present invention and the following formula (320) as the photosensitized metal complex dye described in Non-Patent Document 2 were used in combination. Or as the compound of the formula (321) of the light-sensitizing organic pigment described in patent document 2) deployment is made into 1.6 * 10 -4 The EtOH solution of M was used to support two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com