Preparation method of water reducing agent for electronic ceramic spraying granulation slurry

A technology of spray granulation and electronic ceramics, which is applied in the field of preparation of water reducers for spray granulation slurry of electronic ceramics. Good stability, no color change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

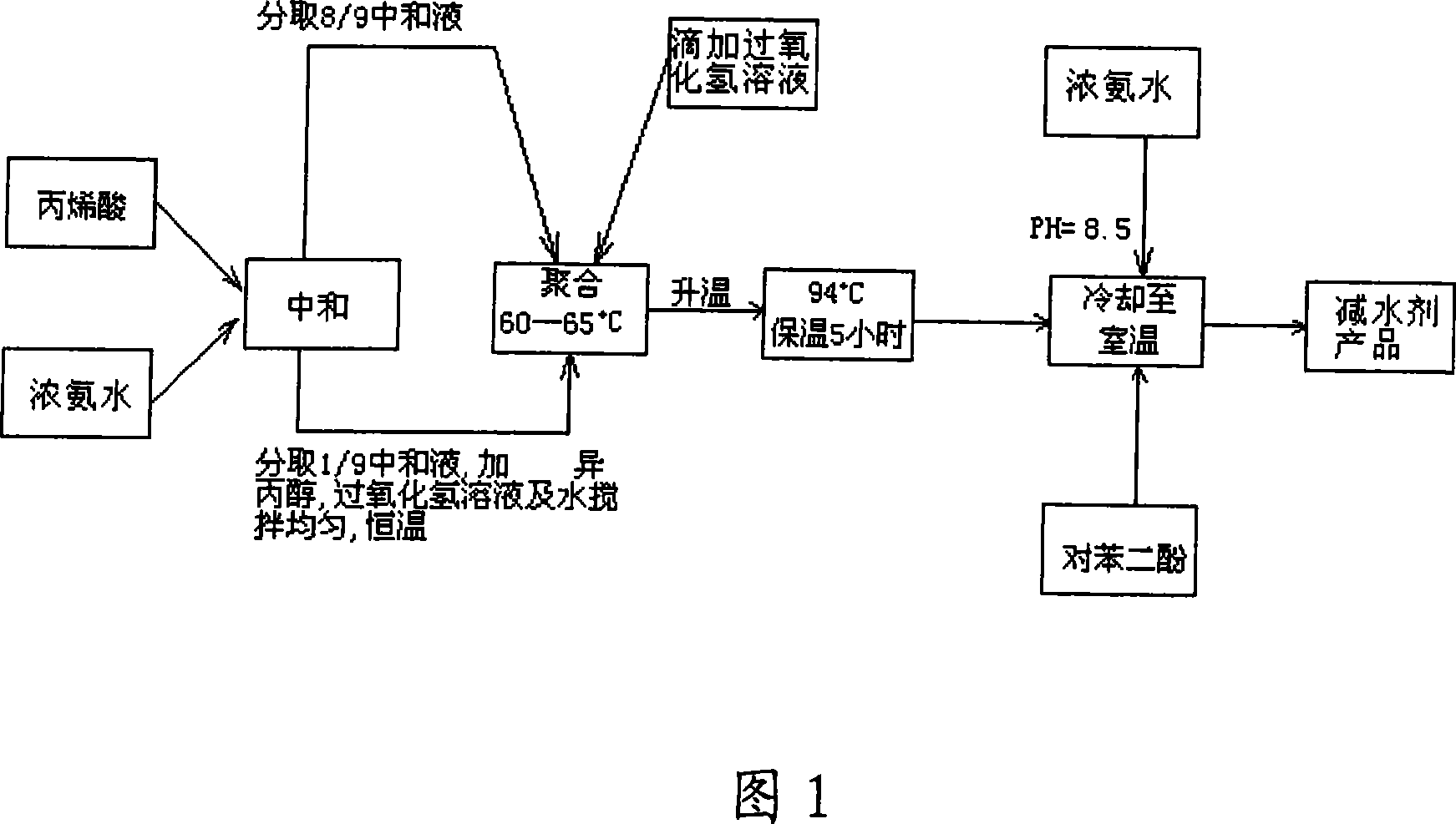

[0024] A method for preparing a water reducer for electronic ceramic spray granulation slurry, comprising the following steps:

[0025] (1) Proportioning the following component raw materials:

[0026] Raw material specification dosage (mol percentage)

[0027] Acrylic acid Polymer grade, >99% 7.1236

[0028] Concentrated ammonia, analytically pure, 28% 10.5522

[0029] Hydrogen peroxide solution Analytical grade, 30% 1.0502

[0030] Secondary deionized water 79.2388

[0031] Isopropanol Chemically pure, >98% 2.0378

[0032] Hydroquinone Analytical grade 0.0023

[0033] (2) According to the ratio, acrylic acid is pumped into the neutralization reactor through the vacuum system, and neutralized with concentrated ammonia water until pH=9-10.

[0034] (3) Take one-ninth of the weight of the neutralizing solution, then add isopropanol, water, and hydrogen peroxide solution with a ratio of 2 / 3 according to the proportion, stir evenly, and then mix with eight-ninths of the wei...

Embodiment 2

[0037] In step (1), except that the concentration of strong ammonia water is 26%, steps (1), (2), and (3) are the same as in Example 1, and in step (4), after the polymerization solution is cooled to 25° C., add the hydroquinone, and drop concentrated ammonia water, neutralize the solution to PH=8, stop stirring, and obtain a weakly alkaline water reducer product.

Embodiment 3

[0039] In step (1), except that the concentration of strong ammonia water is 25%, steps (1), (2), and (3) are the same as in Example 1, and in step (4), after the polymerization solution is cooled to 25° C., add the hydroquinone, and dropwise added concentrated ammonia water, the solution was neutralized to PH=8.5, and the stirring was stopped to obtain another weakly alkaline water reducer product.

[0040] Examples of the application of the water reducing agent of the present invention in the preparation of zinc oxide resistors:

[0041] 1. Addition amount: between 0.4% and 1.1% of the dry material amount, and select the best addition amount through experiments (generally, the solid content of the spray-dried granulation slurry is about 65%, and the water content is about 35%).

[0042] 2. How to join

[0043] First, the amount of water that should be added according to the formula requirements is divided into three appropriate parts: respectively used to dilute the optimal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com