Long life high capacity bipolar-type pole plate lead acid battery for electric automobile

A technology of lead-acid batteries and lead-acid batteries, which is applied to electric vehicles, lead-acid batteries, electrodes of lead-acid batteries, etc. It can solve the problems of high heat in battery cells, reduced battery capacity, and damaged batteries, so as to reduce the possibility and Occurrence rate, effect of increasing discharge depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment one: bipolar polar plate (10)

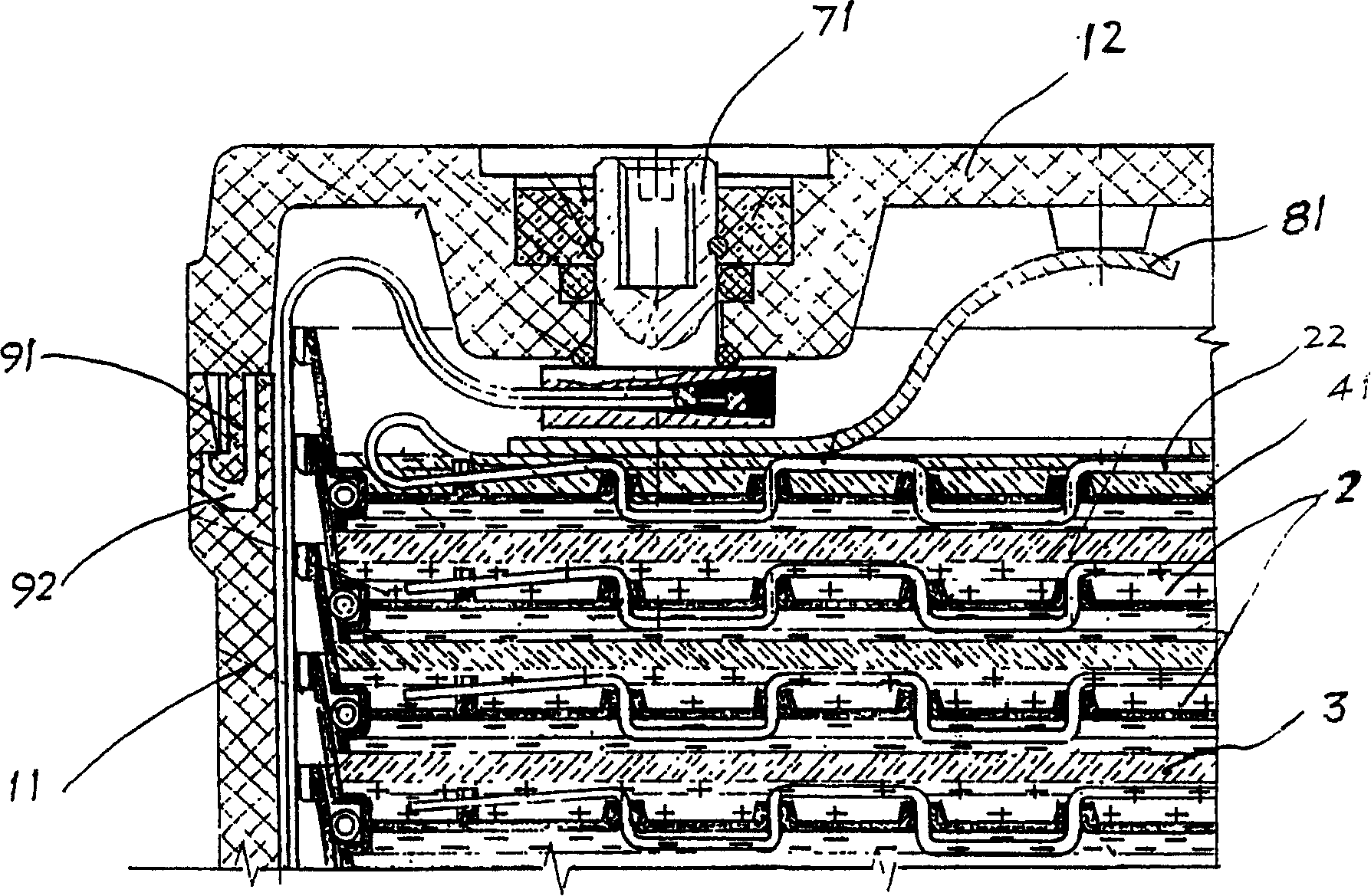

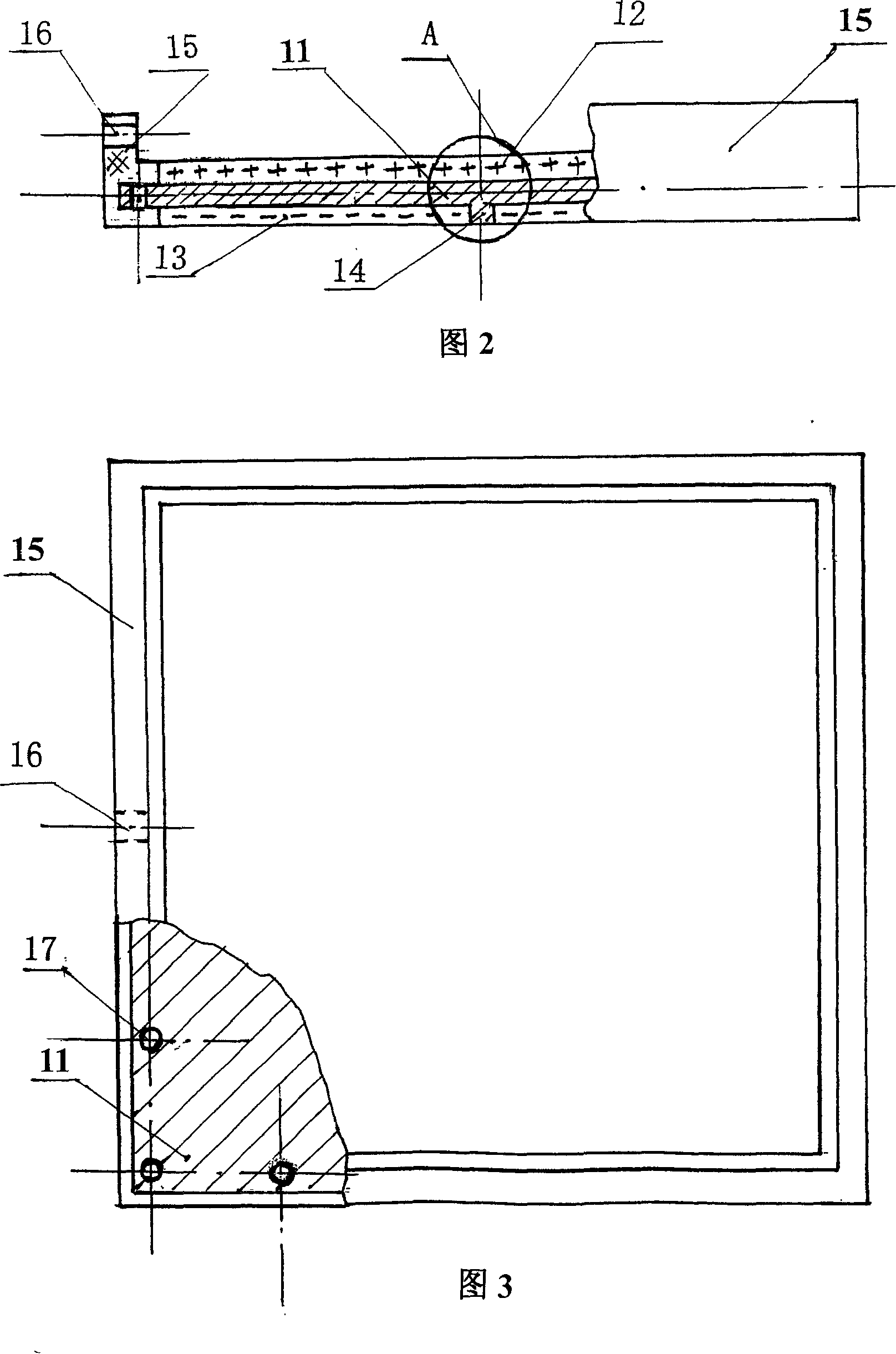

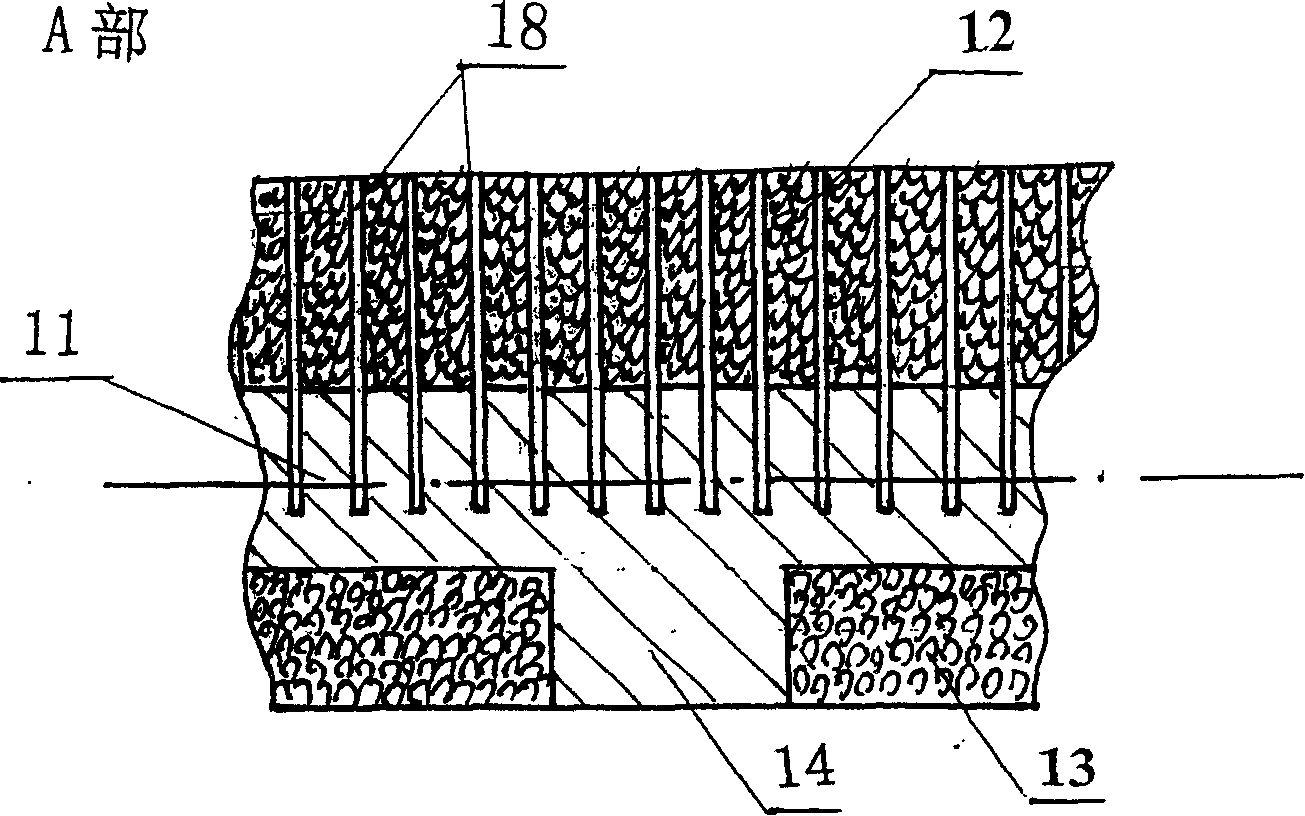

[0042] See Figure 2, Figure 3, Figure 4 , the bipolar plate (10) is composed of a substrate (11), a conductive pin (18), a conductive column (14), a positive active material layer (12), a negative active material layer (13) and a plastic frame (15).

[0043] On the die-casting machine, extrude the parts with conductive pins (18), conductive columns (14), and substrates (11) at one time, for the convenience of compounding plastic frame (15) around the substrate (11), on the substrate (11) ) to set up a plurality of compound plastic reinforcing holes (17) around. The thickness of the substrate (11) should be as thin as possible if the process allows. The recommended thickness is 1-0.1mm. The material of the substrate (11) can be any metal with conductivity and formability. Lead, titanium, stainless steel and lead are recommended. alloy, titanium alloy material. In order to adapt to the corrosive environment of these materials...

Embodiment 2

[0044] Embodiment 2: bipolar pole plate (10).

[0045]The second embodiment of the bipolar pole plate (10) is: the conductive needle (18) is manufactured independently, and the material is titanium or titanium alloy, stainless steel, and other metals such as copper and aluminum are also desirable. Place the conductive needle (18) in the mold, die-cast the base plate (11) and the conductive column (14) with molten metal, and die-cast the conductive pin (18), the base plate (11) and the conductive column (14) into a whole, and the molten metal recommends With lead, titanium or their alloys and stainless steel, implementation process is with embodiment one thereafter.

Embodiment 3

[0046] Embodiment three: bipolar plate (10)

[0047] The third embodiment of the bipolar pole plate (10) is: after the positive side of the substrate (11) with conductive pins (18) is modified with an inorganic conductive layer, that is the composite plastic frame (15). A modification of an organic conductive layer. Other implementation processes are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com