Method for preparing biodiesel by grease biotransformation in solvent-free system

A biodiesel and bioconversion technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, biofuels, etc., can solve the problems of high catalyst preparation costs, easy to block pipelines, and affect reactions, so as to alleviate the increasingly tight supply and reduce production Cost, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

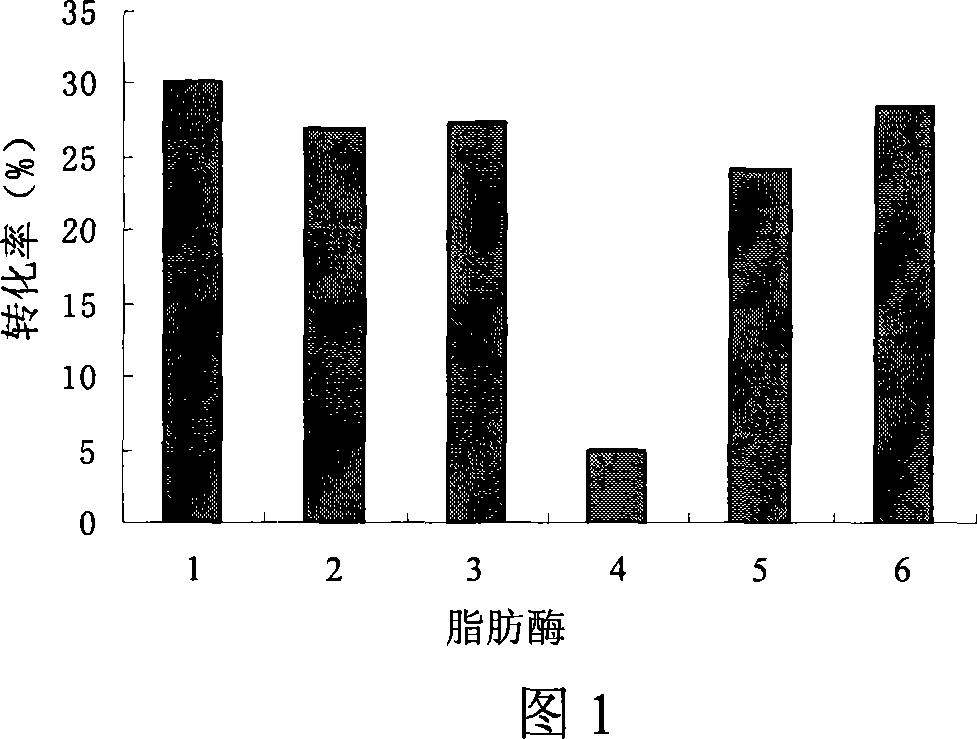

[0039] Embodiment 1: the selection of biocatalyst lipase

[0040] Soybean oil (9.65g) with a molar ratio of 1:1 and methanol in a solvent-free system, the conversion of 6 lipases with the same ester synthase activity unit on a constant temperature shaker at 30°C for 24 hours ,As shown in Figure 1. (1) Novo 435 has the best conversion effect, and the yield of fatty acid methyl ester can reach about 30%, that is, the conversion rate of methanol can reach more than 90%; Compared with Novo 435, the effect is not much different, and the conversion rate of methanol can reach more than 90%.

Embodiment 2

[0041] Embodiment 2: be the methyl alcohol and leprosy seed oil (9.65g of leprosy seed oil 9.65g) that total molar ratio is 4: 1 and the Rhizopus chinensis CCTCC M201021 whole cell lipase of 10% based on grease quality and 2% pH 7.5 phosphate buffers Put it into a 50mL Erlenmeyer flask with a stopper, place it in a temperature-controllable air shaker, add methanol three times at 10h, 24h, and 48h, shake at 30°C for 72h, and the yield of biodiesel is 95%.

Embodiment 3

[0042] Embodiment 3: Methanol and acid value oil (acid value oil 9.65g, acid value 50) that total molar ratio is 3: 1 and Rhizopus chinensis CCTCC M201021 whole cell lipase and 2% pH 7.5 based on grease quality 10% The phosphate buffer solution was put into a 50mL Erlenmeyer flask with a stopper, placed in a temperature-controllable air shaker, and methanol was added twice at 10h and 24h respectively, and shaken at 30°C for 48h, and the yield of biodiesel could reach 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com