Electrically conducting transparent film and its preparing process

A technology of transparent conductive film and zinc magnesium oxide film, which is applied to conductive layers, oxide conductors, non-metallic conductors and other directions on insulating carriers to achieve the effects of good electro-optical performance, control of doping amount and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Clean the glass substrate and place it on the sample holder of the reaction chamber of the DC reactive magnetron sputtering device, with the substrate deposition surface facing down, which can effectively prevent the contamination of the substrate surface by granular impurities. The vacuum degree of the reaction chamber is evacuated to 3×10 -3 Pa, using zinc-magnesium-gallium alloy as the target material, the molar percentage of gallium is 5.0%, the molar percentage of magnesium is 10%, with Ar with a purity of 99.99% and O with a purity of 99.99% 2 As the sputtering gas, the two gases are respectively controlled by the flow meter into the reaction chamber, Ar:O 2 =4:1, the pressure of the reaction chamber is 1.5Pa. Sputtering was started at a power of 100W, the substrate temperature was 300°C, and the growth time was 10min, a transparent conductive film with a thickness of about 500nm was obtained.

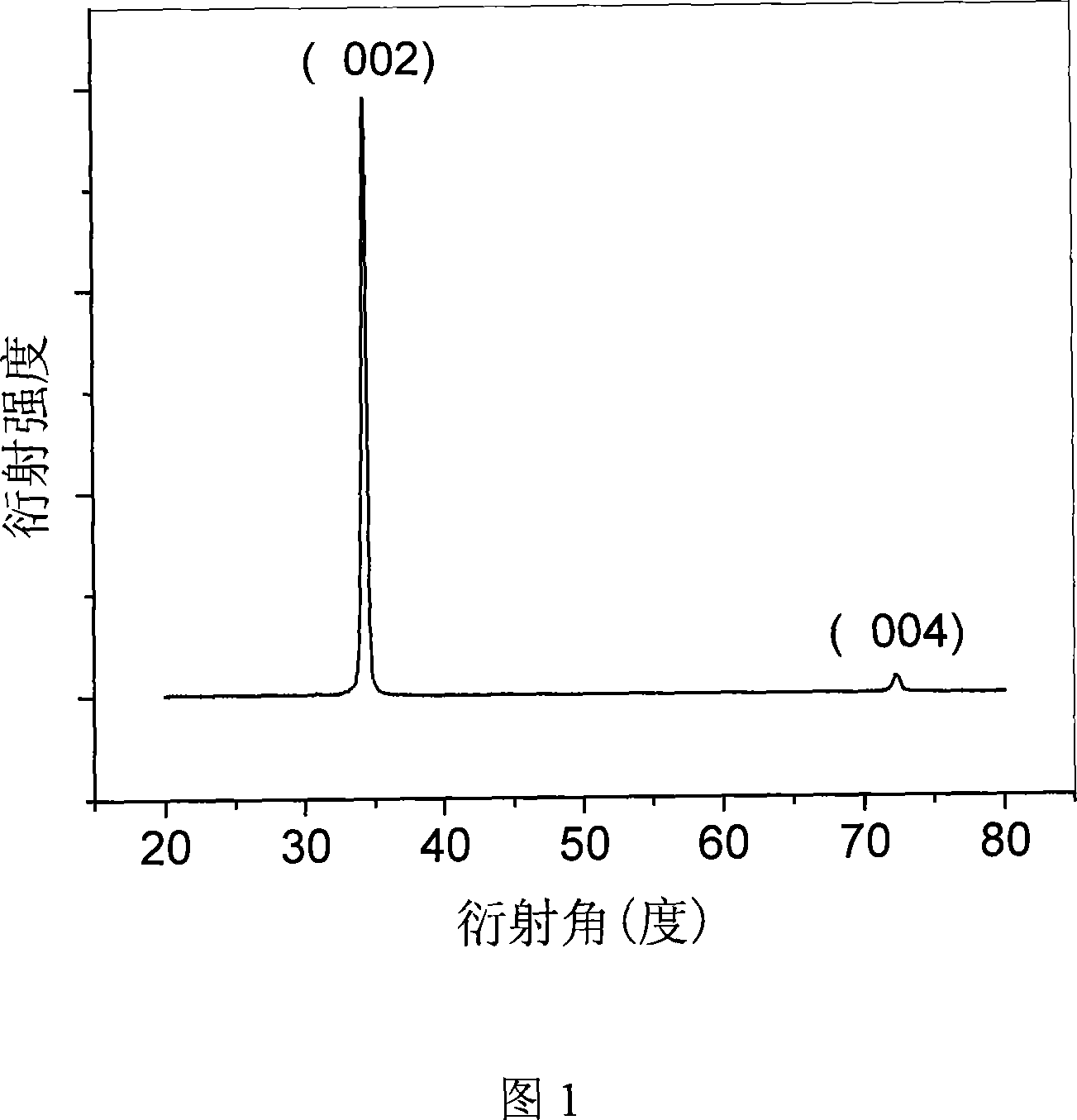

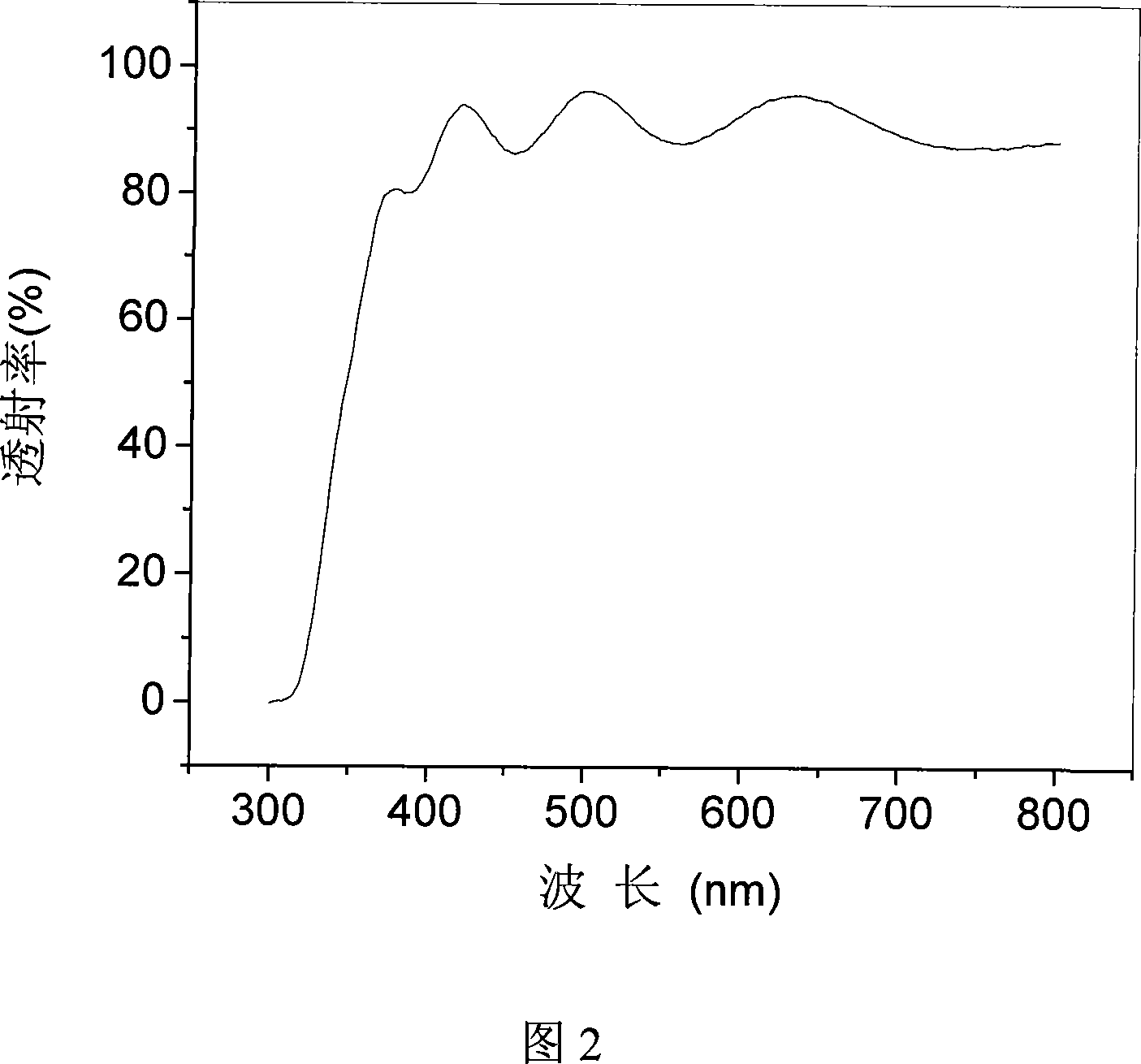

[0018] The prepared gallium-doped zinc-magnesium-oxygen transparent...

Embodiment 2

[0022] Clean the silicon wafer substrate and place it on the sample holder of the reaction chamber of the DC reactive magnetron sputtering device. to 3×10 -3 Pa, using zinc-magnesium-aluminum alloy as the target material, the molar percentage of aluminum is 1.0%, the molar percentage of magnesium is 1%, and the Ar with a purity of 99.99% and O with a purity of 99.99% 2 As the sputtering gas, the two gases are respectively controlled by the flow meter into the reaction chamber, Ar:O 2 =8:1, the pressure of the reaction chamber is 2.0Pa. Sputtering was started at a power of 100W, the substrate temperature was 200°C, and the growth time was 10min, a transparent conductive film with a thickness of about 500nm was obtained.

[0023] The prepared aluminum-doped zinc-magnesium-oxygen transparent conductive film has excellent electro-optical properties at room temperature. In this embodiment, the film resistivity is 5.0×10 -4 Ω·cm, Hall mobility is 7.8cm 2 / V.s, the electron carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com