Production method of lithium ion power cell ferrous phosphate lithium composite material

A lithium iron phosphate, power battery technology, applied in electrode manufacturing, phosphorus compounds, battery electrodes, etc., can solve the problems of difficult to obtain single-phase LiFePO, low utilization rate of active materials, difficult lithium ion diffusion, etc., and achieve excellent cycle performance. , excellent electrical conductivity and high current charge-discharge performance, and the effect of high synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 8 g Fe 2 o 3 and 10.4 g LiH 2 PO 4 According to the stoichiometric ratio of 1:1, add 1.6 grams of phenolic resin (polyacene after carbonization) and 3.2 grams of sucrose, ball mill in ethanol solution for 5 hours, then spray dry, and carry out temperature programming in nitrogen atmosphere , raised at 5°C / min to 800°C for 3 hours, then cooled rapidly.

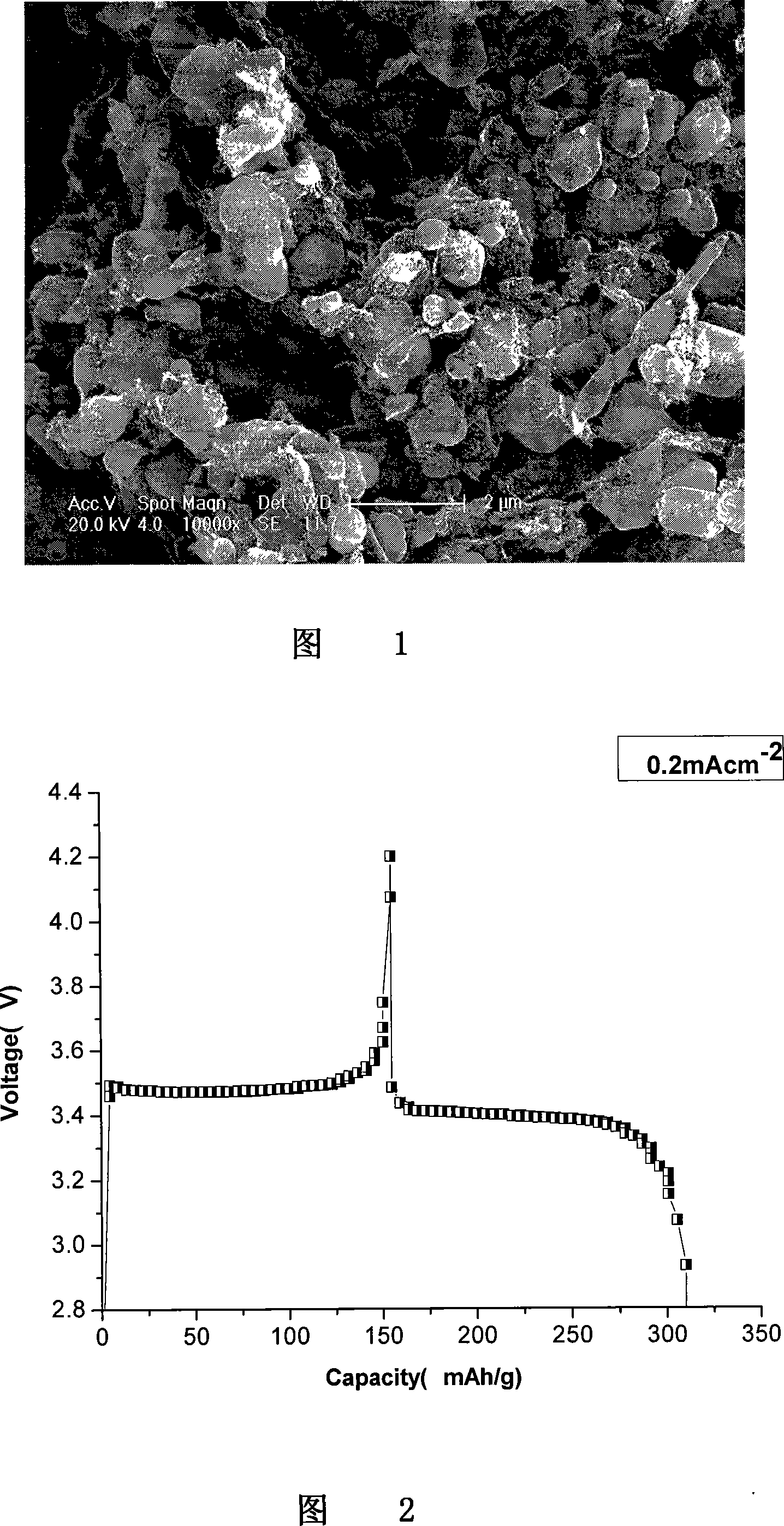

[0020] The SEM image of the obtained composite material measured is shown in Figure 1, and a spherical lithium iron phosphate composite material with uniform particle size was synthesized.

[0021] The composite material that obtains with embodiment 1 is made electrode by following method:

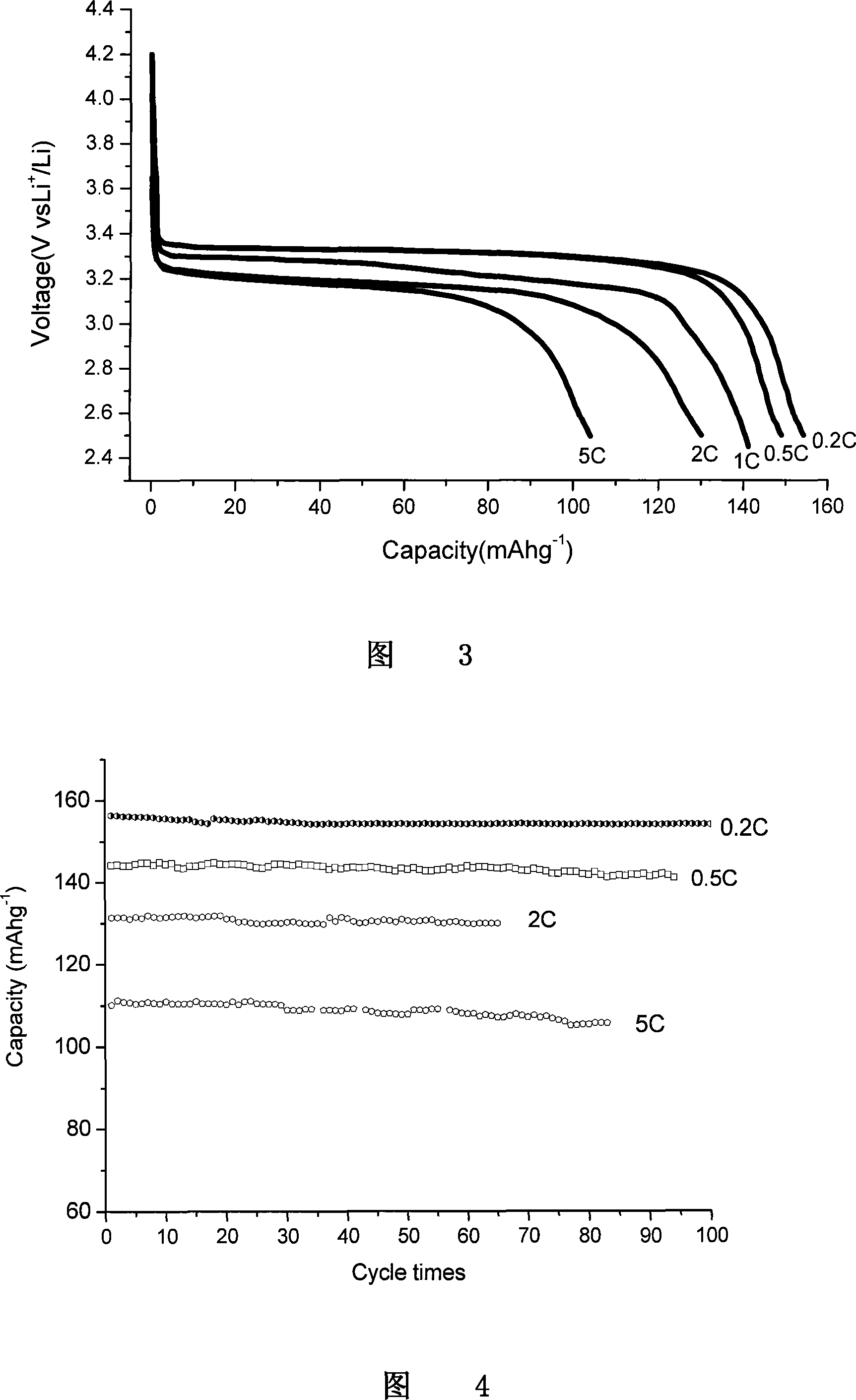

[0022] Take the composite material obtained in Example 1 at a mass ratio of 80:10:10: acetylene black: polytetrafluoroethylene, and grind them evenly to make an electrode. 1mol / L LiPF in a mixed solvent of dimethyl ester (1:1 by volume) 6 As the electrolyte, polypropylene microporous membrane as the diaphragm, assembled into a ...

Embodiment 2

[0024] O.1mol H 3 PO 4 , 0.1mol LiOH·H 2 O, 0.05mol Fe 2 o 3 Proportioning according to stoichiometric ratio, then add 1.6 grams of phenolic resin (accounting for 10% of synthetic lithium iron phosphate mass) and 1.6 grams of glucose, ball mill in acetone solution for 4 hours, spray dry, carry out temperature program in nitrogen atmosphere , raised to 700°C at 5°C / min, kept for 8 hours, cooled rapidly and then ground. The simulated battery was assembled in the same way, and the first discharge capacity at 1C rate can reach 140mAh / g.

Embodiment 3

[0026] 0.1mol NH 4 h 2 PO 4 , 0.1mol LiOH·H 2 O, 0.05mol Fe 2 o 3 According to the stoichiometric ratio, add 0.8 grams of polyaniline (accounting for 10% of the synthetic lithium iron phosphate mass) and 3.2 grams of glucose, ball mill in an aqueous solution for 3 hours, spray dry, and carry out a temperature program in a nitrogen atmosphere , raised to 750°C at 3°C / min, kept for 5 hours, cooled rapidly and then ground. The simulated battery was assembled in the same way, and the first discharge capacity at 1C rate can reach 138mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com