Integrated opto-electronic device for generating high-frequency microwave by light heterodyne method

An optoelectronic device and high-frequency microwave technology, applied in the field of microwave photonics, can solve the problems of short transmission distance, high absorption loss and high cost, and achieve the effect of monolithic integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

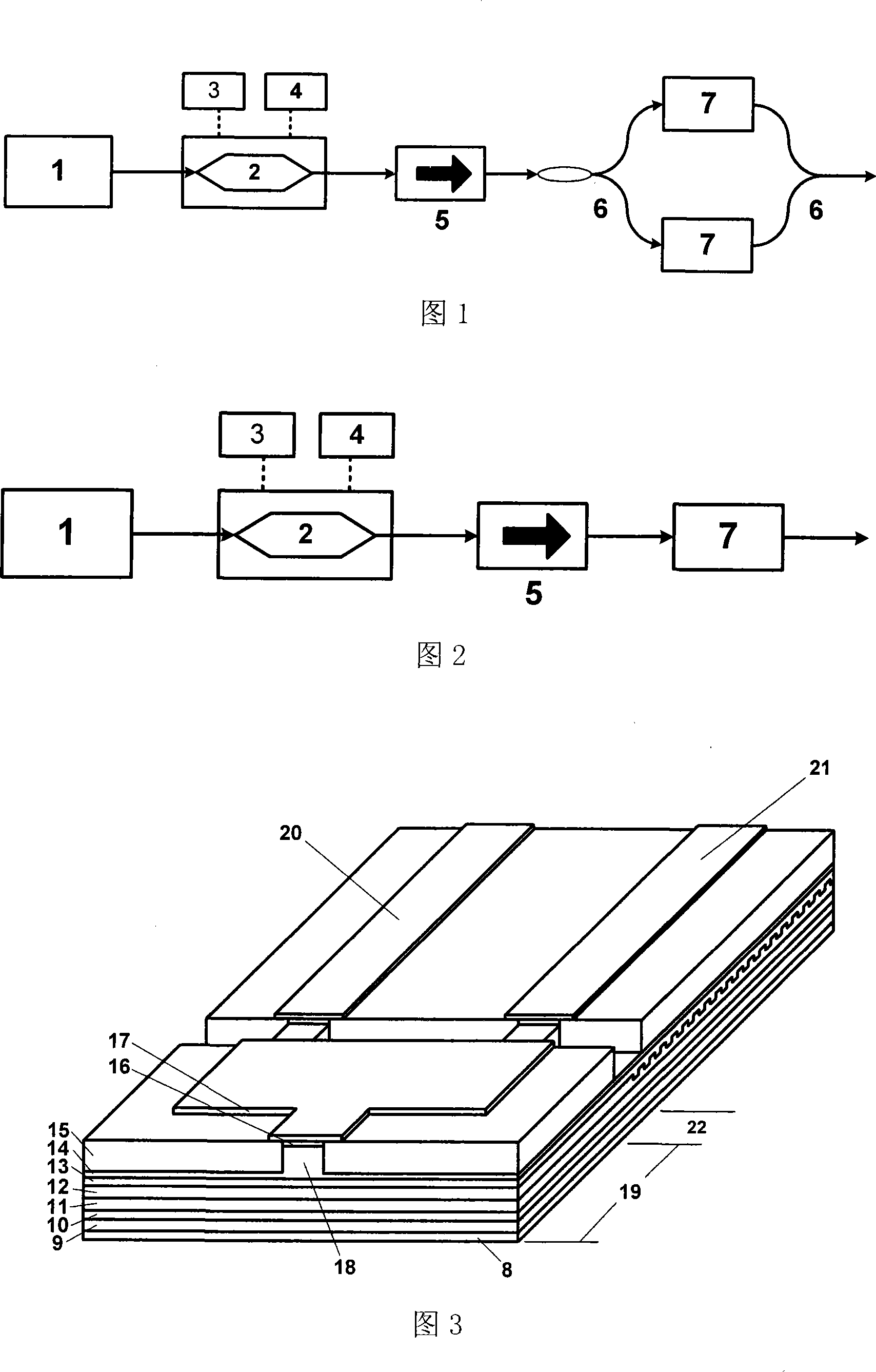

[0044] Embodiment 1 An InGaAsP / InP-based single-ended MMI coupled photo-generated microwave integrated device with an operating wavelength within the 1550nm band (the structure shown in FIG. 3 ).

[0045] The epitaxial materials for the devices are described below. First, an epitaxial, n-type InP buffer layer (thickness 200nm, doping concentration about 1×10 18 cm -2 ), 100nm thick undoped lattice-matched InGaAsP waveguide layer (photoluminescence wavelength 1.2μm), strained InGaAsP multiple quantum wells (photoluminescence wavelength 1.52μm, 7 quantum wells: well width 8nm, 0.5% compressive strain, barrier width 10nm , Lattice matching material, photofluorescence wavelength 1.2μm), 70nm thick InGaAsP grating material layer. Next, the grating structure is fabricated by holographic interference exposure, and the grating in the MMI region is removed by photolithography and wet etching. Then secondary epitaxial 100nm thick p-type lattice matching InGaAsP waveguide layer (light...

Embodiment 2

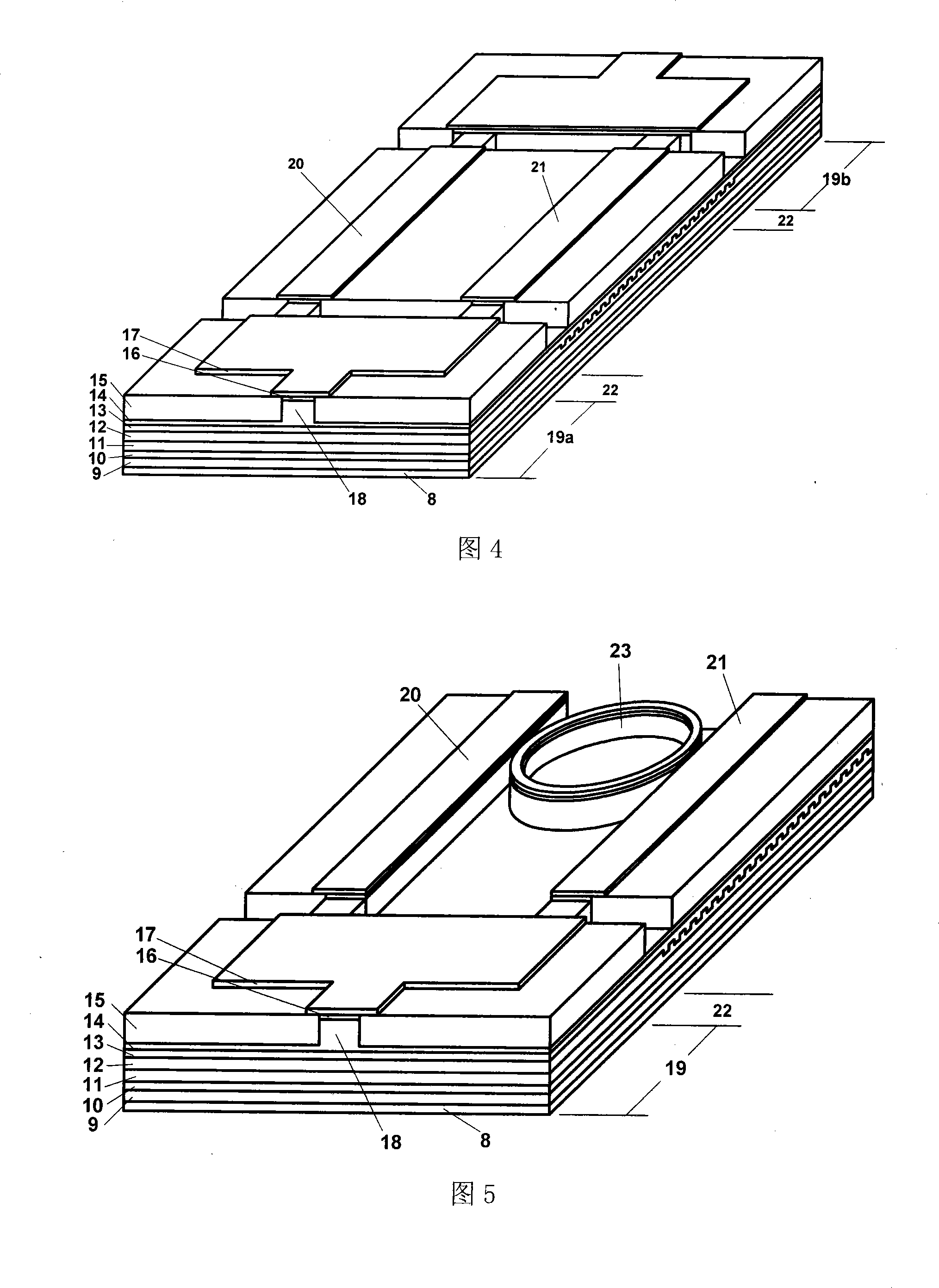

[0048] Embodiment 2 An InGaAsP / InP-based double-terminal MMI coupled photo-generated microwave integrated device with an operating wavelength within the 1550nm band (the structure shown in FIG. 4 ).

[0049] The epitaxial materials for the devices are described below. First, an epitaxial, n-type InP buffer layer (thickness 200nm, doping concentration about 1×10 18 cm -2 ), 100nm thick undoped lattice-matched InGaAsP waveguide layer (photoluminescence wavelength 1.2μm), strained InGaAsP multiple quantum wells (photoluminescence wavelength 1.52μm, 7 quantum wells: well width 8nm, 0.5% compressive strain, barrier width 10nm , Lattice matching material, photofluorescence wavelength 1.2μm), 70nm thick InGaAsP grating material layer. Next, the grating structure is fabricated by holographic interference exposure, and the grating in the MMI region is removed by photolithography and wet etching. Then secondary epitaxial 100nm thick p-type lattice matching InGaAsP waveguide layer (li...

Embodiment 3

[0052] Embodiment 3 An InGaAsP / InP-based microring-coupled photo-generated microwave integrated device with an operating wavelength in the 1550nm band (the structure shown in FIG. 5 ).

[0053] The epitaxial materials for the devices are described below. First, an epitaxial, n-type InP buffer layer (thickness 200nm, doping concentration about 1×10 18 cm -2 ), 100nm thick undoped lattice-matched InGaAsP waveguide layer (photoluminescence wavelength 1.2μm), strained InGaAsP multiple quantum wells (photoluminescence wavelength 1.52μm, 7 quantum wells: well width 8nm, 0.5% compressive strain, barrier width 10nm , Lattice matching material, photofluorescence wavelength 1.2μm), 70nm thick InGaAsP grating material layer. Next, the grating structure is produced by holographic interference exposure, and the grating in the microring and MMI area is removed by photolithography and wet etching. Then secondary epitaxial 100nm thick p-type lattice matching InGaAsP waveguide layer (light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com