Reutilizing method for phenol coke tar waste slag

A technology of tar waste residue and phenol tar, which is applied in the field of phenol tar waste residue as an unsaturated compound monomer polymerization inhibitor, can solve the problems of unsuitable tar waste residue, energy waste, and toxic gas pollution, and achieve low cost and polymerization inhibition effect Good, low equipment investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0015] Under the conditions of no air and a temperature of 120°C, acrylic acid with a purity of 99.8% after rectification is used as a raw material. The tar waste residue powder was used as a polymerization inhibitor alone, and the polymerization inhibition experiment was carried out in a 50ml pear-shaped bottle by heating with silicone oil. The results are shown in Table 1.

[0016] Table 1 tar powder alone is the experimental result of polymerization inhibitor

[0017] Example

Amount added / ppm

temperature / ℃

Induction period / h

1

100

120

84

2

200

120

230

3

300

120

378

4

400

120

646

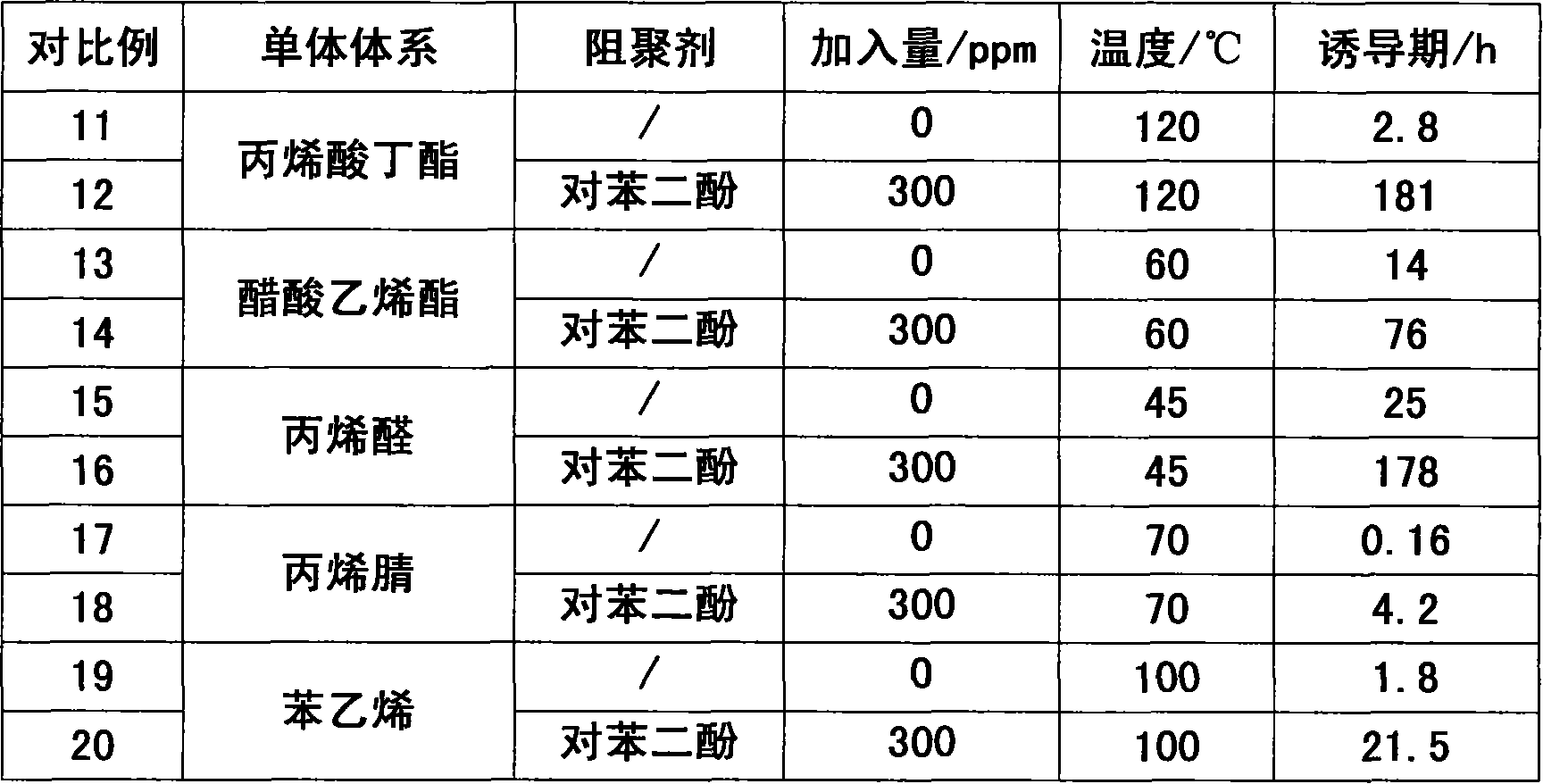

[0018] The hydroquinone of the same addition amount of table 2 is used as polymerization inhibitor experimental result

[0019] comparative example

Embodiment 5-9

[0023] Experimental condition is the same as embodiment 1. The tar waste residue powder was compounded with one of the copper salt compounds, nitrogen oxide free radical compounds, phenols and amine compounds, and the polymerization inhibition experiment was carried out in a 50ml pear-shaped bottle heated with silicone oil. The experimental results are shown in Table 3.

[0024] Table 3 Binary composite polymerization inhibitor experimental results

[0025] Example

Embodiment 10-13

[0033] Experimental condition is the same as embodiment 1. The tar waste residue powder was compounded with two kinds of copper salt compounds, nitrogen oxide free radical compounds, phenols and amine compounds, and the polymerization inhibition experiment was carried out in a 50ml pear-shaped bottle by heating with silicone oil. The experimental results are shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com