Biological fertilizer and manufacture method thereof

A technology of bio-fertilizer and enzyme bacteria, applied in the field of bio-fertilizer, can solve the problems of poor compatibility, insignificant comprehensive treatment effect, poor efficiency of urban sludge, etc., and achieve low cost, good complexation adsorption performance, and strong adsorption force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

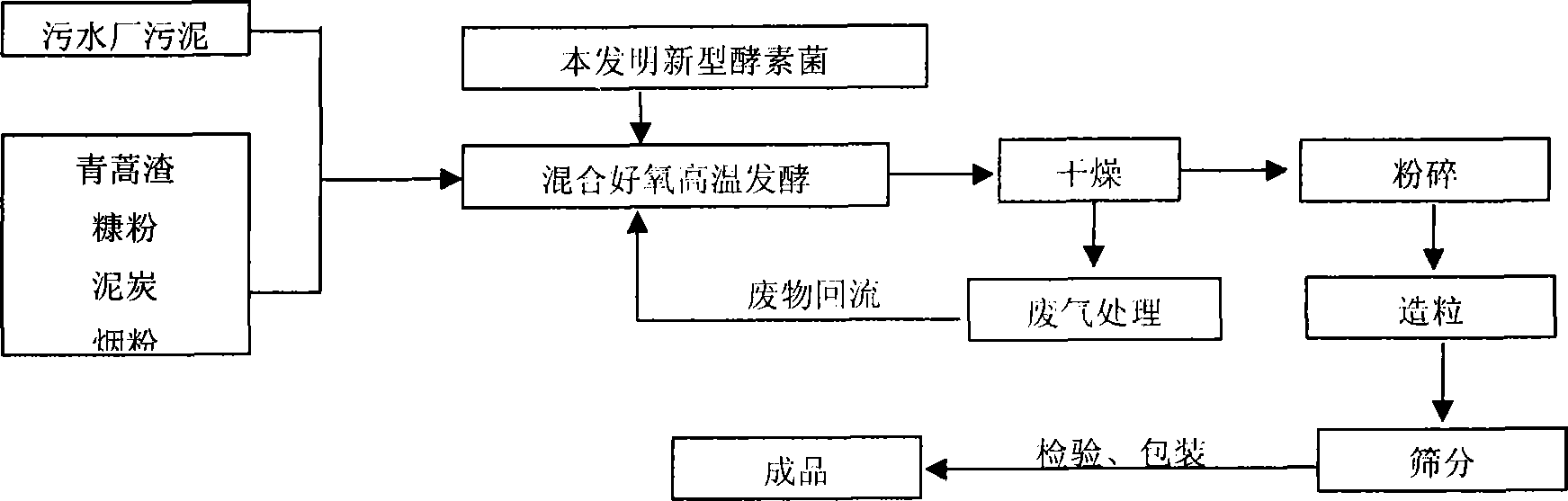

Method used

Image

Examples

Embodiment

[0040] 1. Isolation of Bacillus megaterium M1

[0041] Evenly mix 5-10g of commercially available enzyme bacteria with 5-10g of nutrient-based cornstarch, 5-10g of brown sugar and 10-20g of wheat bran, pH6.0-7.0, humidity control at 30-35%, and then add hydroxylamine or ethyl alcohol The imine is 0.005-0.05g, the temperature is 25-35°C, and the temperature difference is 8-10°C. After 2-3 days of cultivation, the Bacillus megaterium M1 is screened out with an inoculation loop. The nutrient base may also include at least one of 3-5 g of fish meal, 3-5 g of vegetable cake and 35-50 g of polished rice bran.

[0042] 2. Cultivation of Bacillus megaterium M1

[0043] Bacillus megaterium M1 grows on the following media:

[0044] Sucrose 50g (NH 4 ) 2 SO 4 6g NgSO 4 2.5g (NH 4 ) 3 SO 4 2g

[0045] K 2 SO 4 2.5g CaSO 4 2.5g agar 1520g distilled water 1000ml pH6.0

[0046] 3. the preparation of biological fertilizer of the present invention

[0047] The novel enzyme ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com