Porous polystyrene chelate resin containing 8-hydroxyquinoline and synthesis process

A technology of porous polystyrene and synthesis process, applied in water/sludge/sewage treatment, water pollutants, adsorption of water/sewage treatment, etc., can solve the problem of low adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

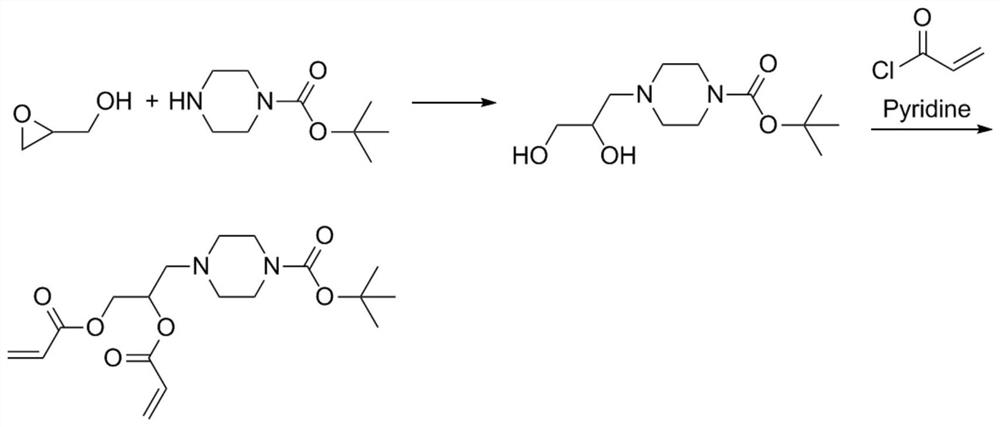

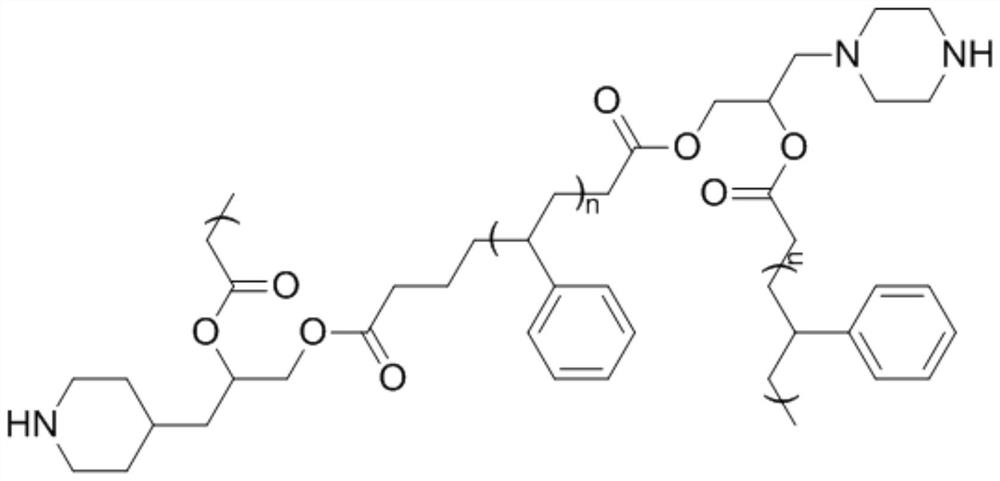

[0030] (1) with glycidol and 1-Boc piperazine as reactant synthetic dihydroxy Boc piperazine compound (C 12 h 24 N 2 o 2 ), then 100 parts (mass parts) of dihydroxy Boc piperazine compounds were added to 600 parts of dichloromethane, 65 parts of acryloyl chloride were added, and 30 parts of catalyst pyridine were added dropwise under ice bath, and then heated to 15 ℃ for 3 hours, after the reaction, distilled under reduced pressure, the product was washed with ether, and then added into ethyl acetate for recrystallization to obtain diacryloyloxy Boc-piperazine compound (C 18 h 28 N 2 o 6 ).

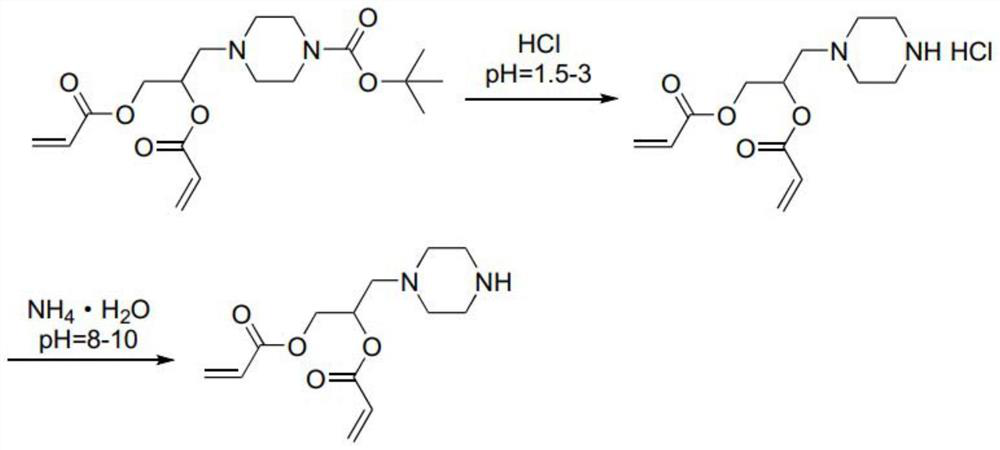

[0031] (2) Add 100 parts (mass parts) of diacryloxy-Boc-piperazine to 500 parts of ethyl acetate, add concentrated hydrochloric acid dropwise under ice bath to adjust the pH to 1.5, react at 15°C for 2h, and then drop Add ammonia water, stir and adjust the pH of the solution to 8, stir evenly, distill under reduced pressure, add ethyl acetate and deionized water for extraction, tak...

Embodiment 2

[0035] (1) with glycidol and 1-Boc piperazine as reactant synthetic dihydroxy Boc piperazine compound (C 12 h 24 N 2 o 2 ), then 100 parts (mass parts) of dihydroxy Boc piperazine compounds are added to 800 parts of chloroform, 72 parts of acryloyl chloride are added, and 38 parts of catalyst pyridine are added dropwise under ice bath, and then heated to 40 ℃ for 3 hours, after the reaction, distilled under reduced pressure, the product was washed with ether, and then added into ethyl acetate for recrystallization to obtain diacryloyloxy Boc-piperazine compound (C 18 h 28 N 2 o 6 ).

[0036] (2) Add 100 parts (parts by mass) of diacryloyloxy Boc piperazine to 800 parts of ethyl acetate, add concentrated hydrochloric acid dropwise under ice bath to adjust the pH to 2, react at 30°C for 5h, then drop Add ammonia water, stir and adjust the pH of the solution to 8, stir evenly, distill under reduced pressure, add ethyl acetate and deionized water for extraction, take the or...

Embodiment 3

[0040] (1) with glycidol and 1-Boc piperazine as reactant synthetic dihydroxy Boc piperazine compound (C 12 h 24 N 2 o 2 ), then 100 parts (mass parts) of dihydroxy Boc piperazine compound was added to 1200 parts of tetrahydrofuran, 82 parts of acryloyl chloride were added, and 48 parts of catalyst pyridine was added dropwise under ice bath, and then heated to 30°C for reaction After 5h, the reaction was distilled under reduced pressure, the product was washed with diethyl ether, and then added into ethyl acetate for recrystallization to obtain the diacryloyloxy Boc piperazine compound (C 18 h 28 N 2 o 6 ).

[0041] (2) Add 100 parts (parts by mass) of diacryloxy-Boc-piperazine to 1200 parts of ethyl acetate, add concentrated hydrochloric acid dropwise under ice bath to adjust the pH to 2, react at 30°C for 6h, then drop Add ammonia water, stir and adjust the pH of the solution to 9, stir evenly, distill under reduced pressure, add ethyl acetate and deionized water for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com