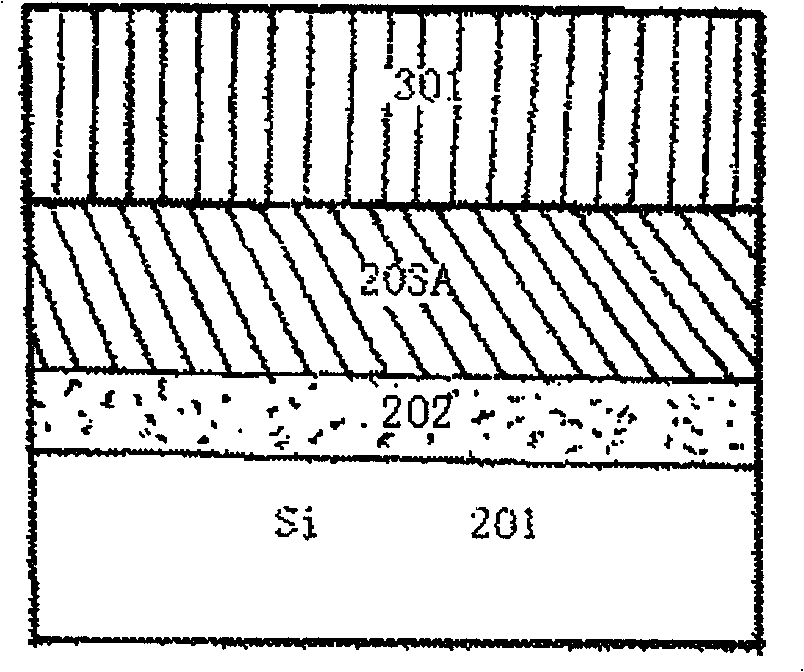

Preparation of strained germanium thin film

A technology of straining germanium and thin films, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of not being able to use large-scale production, increase costs, consume materials, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

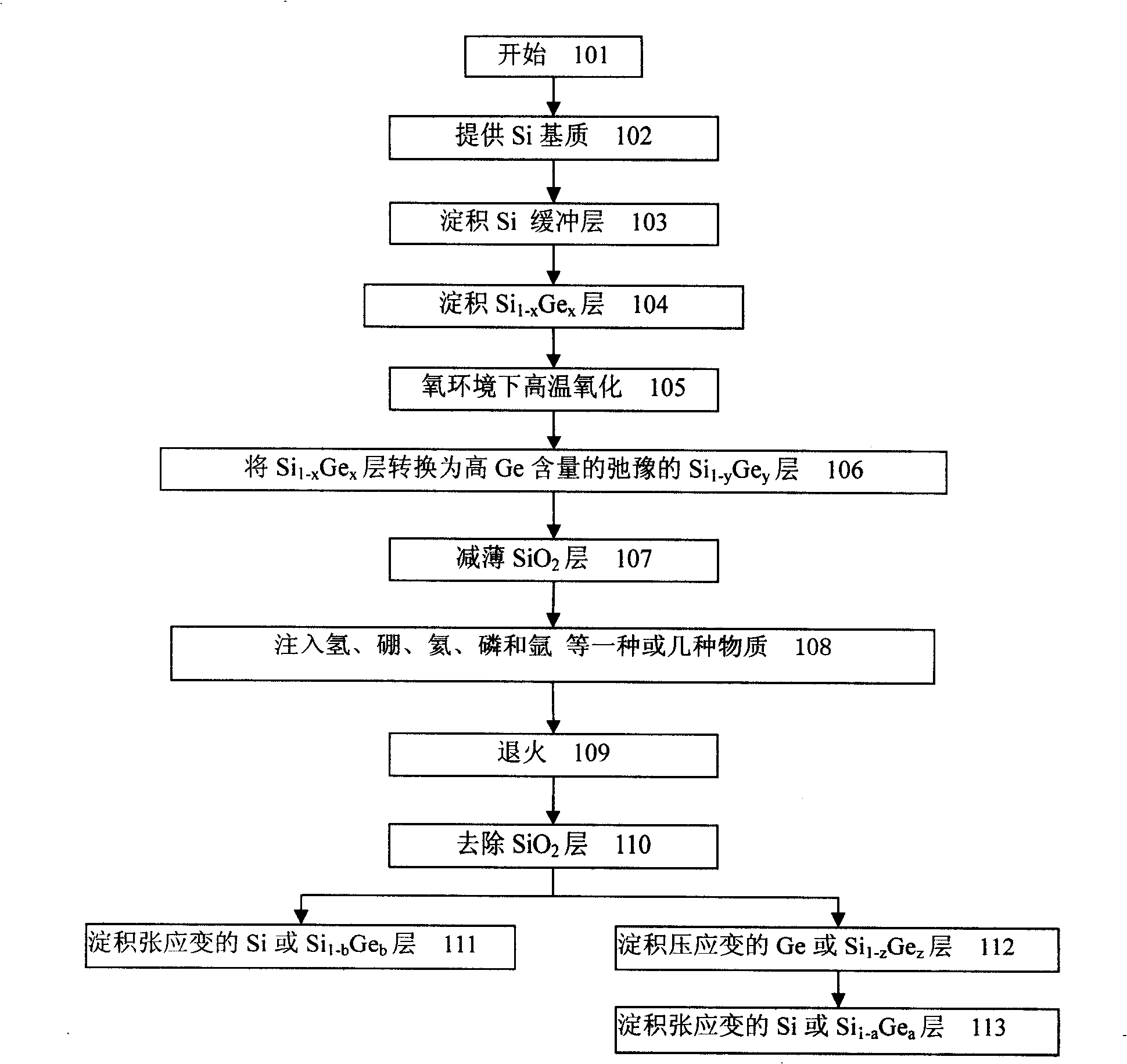

[0054] figure 2 Shown is strained single crystal silicon germanium (Si 1-x Ge x ) Schematic diagram of the cross-section of the substrate. Provided is a strained single crystal silicon germanium (Si 1-x Ge x ) process diagram of the production method of the layer substrate, covering a thickness of 200A on the Si substrate 201 0 The Si buffer layer 202, on the Si buffer layer 202 covers a layer of strained single crystal germanium silicon (Si 1-x Ge x ) layer 203, wherein, Si 1-x Ge x The thickness of the layer is 500A 0 , x=0.3.

Embodiment example 2

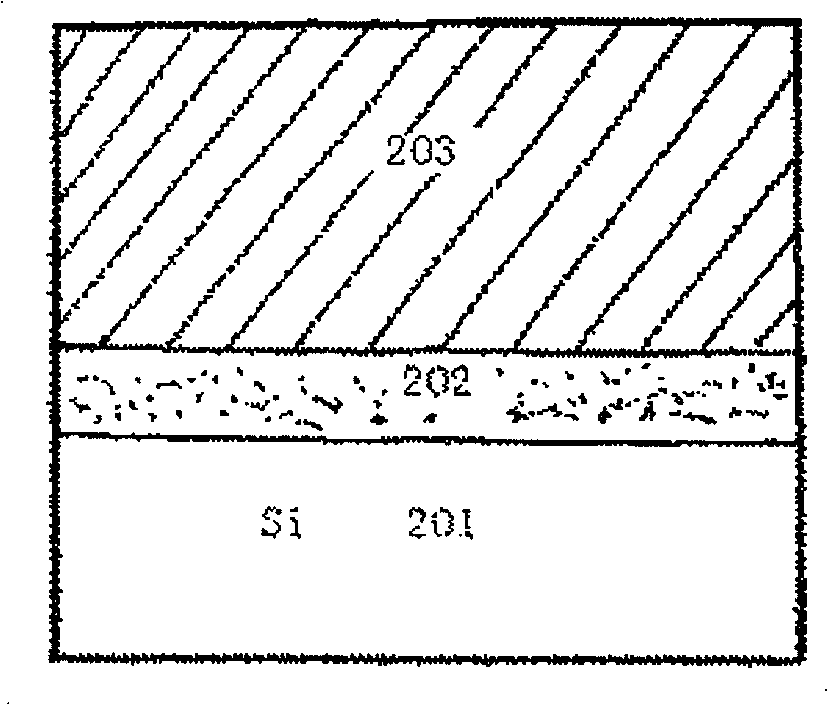

[0056] image 3 Shown is single crystal Si strained by high temperature oxidation 1-x Ge x layer 203, forming a relaxed single crystal Si 1-y Ge y The cross-sectional view of layer 203A and a layer of silicon dioxide film 301, using the method of high temperature oxidation, the strained single crystal germanium silicon (Si 1-x Ge x ) layer substrate 203 is transformed into relaxed Si with high Ge content 1-y Ge y layer 203A and a layer of silicon dioxide film 301, where y=0.6.

[0057] The oxidation environment is dry oxygen, and the oxidation temperature is between germanium silicon (Si 1-x Ge x ) The oxidation rate of the layer 203 is higher than the diffusion rate of Ge atoms in the range. Generally, the higher the temperature, the shorter the oxidation time required, and at the same time, the formed Si with high Ge content 1-y Ge y The Ge concentration in layer 203A is lower. Generally, the oxidation temperature is 900°C, and the oxidation time is 180 minutes. ...

Embodiment example 3

[0059] Such as Figure 4 As shown, for SiGeSi that is not fully relaxed 1-y Ge y Layer 203A is ion-implanted and annealed to form a fully relaxed silicon germanium Si 1-y Ge y Layer 203B. The SiO2 layer 301 is appropriately thinned to form 301A, so as to reduce the implantation energy.

[0060] Si implanted with argon ions 1-y Ge y Layer 203A consists of: 1 x 10 12 / cm 2 The dose is implanted in the energy range of 100keV.

[0061] Annealing includes annealing at a temperature of 800° C. for 60 minutes. Typically, annealing is performed in an atmosphere such as vacuum, nitrogen, argon, or other inert gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com