Method for promoting cellulolytic enzymes synthesis of trichoderma reesei by using dilute sulfuric acid treated pulp as carbon source

A technology for synthesizing cellulose and Trichoderma reesei, which is applied in the field of microbial cultivation in biochemistry, can solve the problems of difficulty in supplying lignocellulose raw materials at the same time, lack of cellulose utilization, and low cellulase activity, so as to benefit microorganisms The effect of using and promoting the growth of bacterial cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

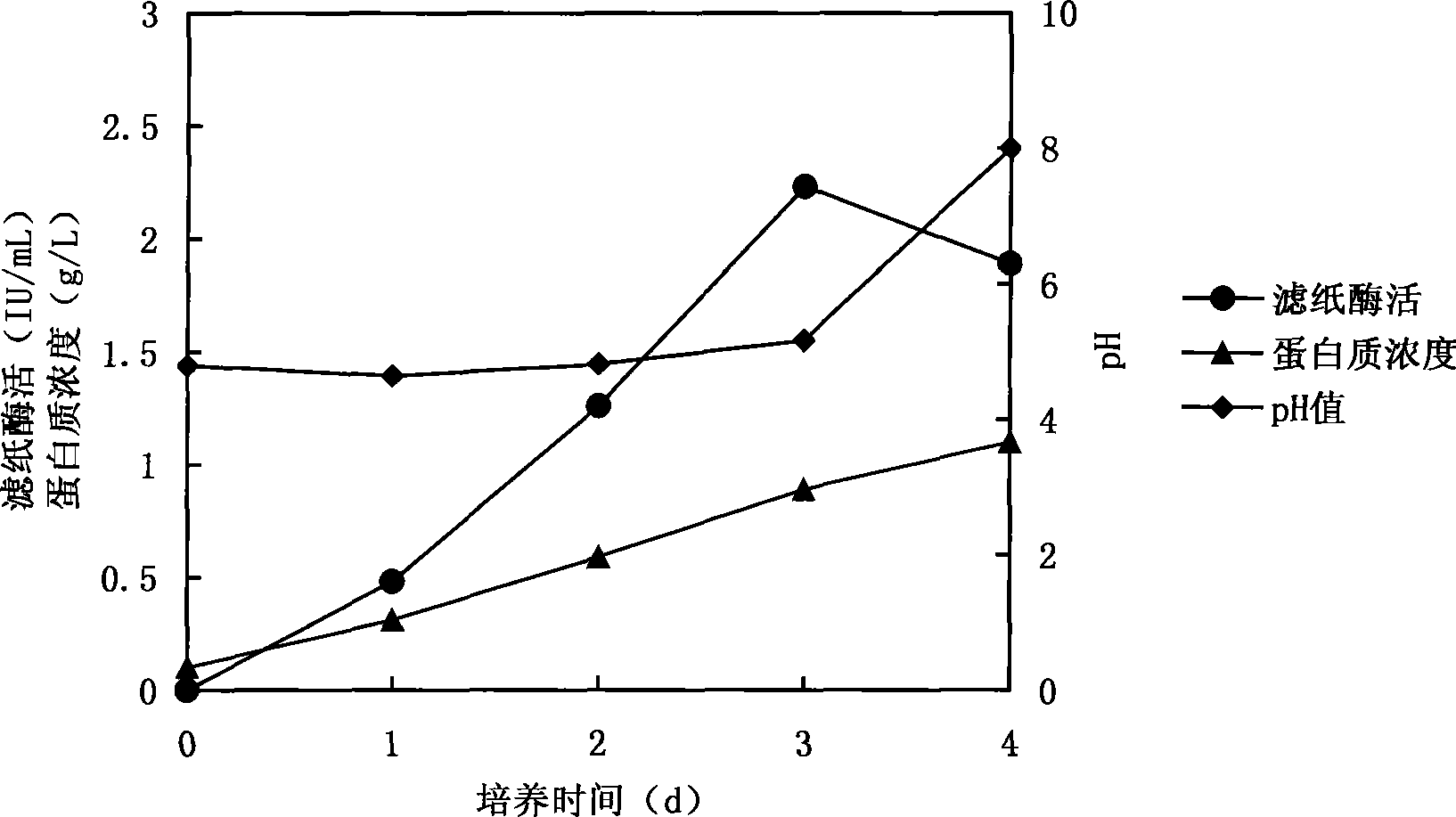

[0021] Cellulase Production by Trichoderma reesei Using Commercial Pure Cellulose as Carbon Source

[0022] Enzyme production medium: commercial pure cellulose (delignified cellulose, Solkc Flock200) 12g / L, glucose 1g / L, peptone 1g / L, ammonium sulfate 2.2g / L, urea 0.5g / L, chloride Calcium 0.3g / L, magnesium sulfate 0.3g / L, ferrous sulfate 0.005g / L, manganese sulfate 0.0016g / L, sulfuric acid 0.0014g / L, cobalt chloride 0.0037g / L, Tween 802 drops / 50mL. The medium was adjusted to pH 4.5-5.0 with citric acid buffer.

[0023] Enzyme production conditions: Trichoderma reesei mycelium is inoculated into the enzyme production medium, and the inoculum amount of Trichoderma reesei mycelium accounts for 10% of the volume of the medium. The culture temperature is 26-32°C, and the rotation speed is 150-250r / min. Samples were taken every other day, centrifuged at 3000r / min, and the supernatant was taken to measure the pH value, filter paper enzyme activity and protein concentration respecti...

Embodiment 2

[0027] Dilute sulfuric acid treatment of pulp

[0028] Crush ordinary commercial pulp into particles with a diameter of about 1 mm, add sulfuric acid solution with a concentration of 0.75-4.0% according to the ratio of solid-liquid ratio of 1:10, soak for 1-5 hours, and then hydrolyze at 110-130 ° C for 40-80 minutes.

[0029] The pulp treated with dilute sulfuric acid is washed with water until neutral, and suction filtered until the moisture content is about 50-80%.

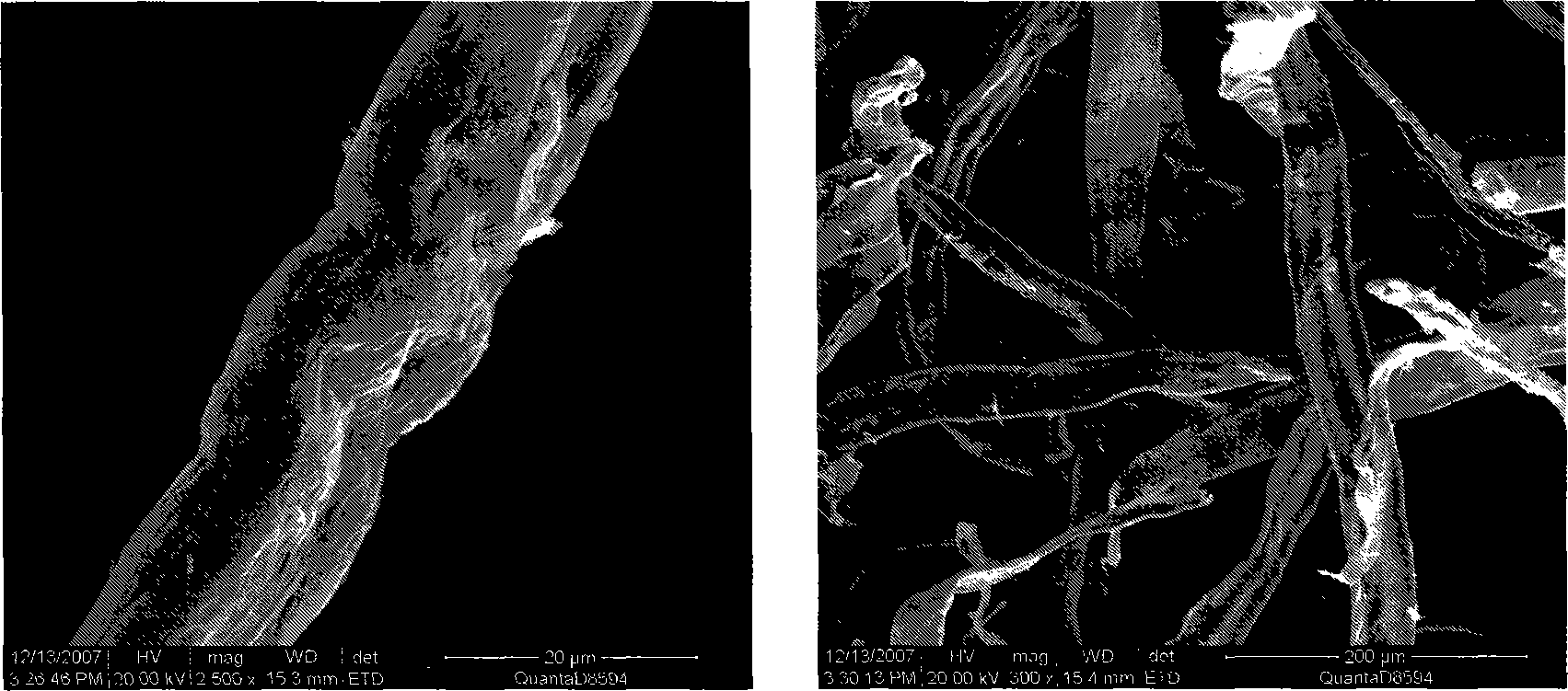

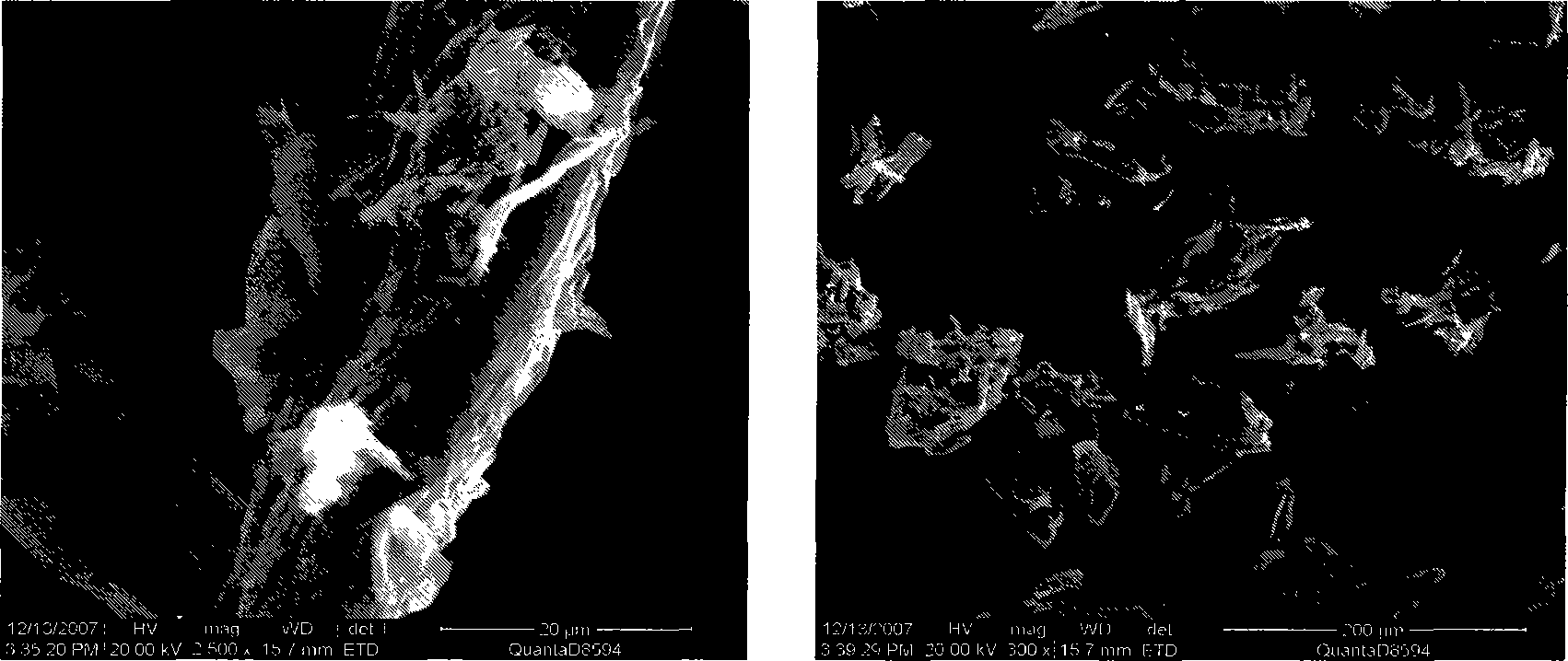

[0030] Carry out electron microscope (SEM) analysis to paper pulp and dilute sulfuric acid treated pulp, electron microscope equipment and operating steps are as follows:

[0031] Equipment: Philips quanta200 electron microscope, Hitachi HCP-2 critical point dryer, Hitachi E-1010 ion sputtering apparatus.

[0032] Dilute sulfuric acid treated pulp sample preparation steps: fixation, gradient dehydration, critical point drying, sticking, conductive treatment.

[0033] Electron microscopy analysis showed that, ...

Embodiment 3

[0036] Trichoderma reesei cellulase production medium was prepared with ordinary pulp and pulp treated with dilute sulfuric acid as carbon source.

[0037] Ordinary pulp and dilute sulfuric acid treated pulp are used in a ratio of 3:1 to 2 to replace the pure cellulose used in Example 1, and the rest are the same as Example 1, and the enzyme production conditions are also the same as Example 1.

[0038] attached by Figure 4 It can be seen that using pulp and dilute sulfuric acid treated pulp as carbon source, the highest enzyme activity of filter paper is 3.12IU / mL, and the enzyme protein concentration is 1.34g / L. Commercial pure cellulose (delignified cellulose, Solkc·Flock200) is a good carbon source for inducing cellulase synthesis, but it is expensive and can only be used for laboratory research. In Example 1, 12 g / L of commercially pure cellulose was used as the carbon source, and the maximum enzyme activity of the filter paper was 2.23 IU / mL. In this example, a mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com