Technique for comprehensive treatment of diesel oil alkaline residue by using circulating technology

A comprehensive treatment and diesel oil technology, applied in the petroleum industry, refining with alkaline aqueous solution, preparation of organic compounds, etc., can solve the problems of low product purity, low raw material utilization rate, high energy consumption, etc., to improve economic benefits, The effect of high product quality and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

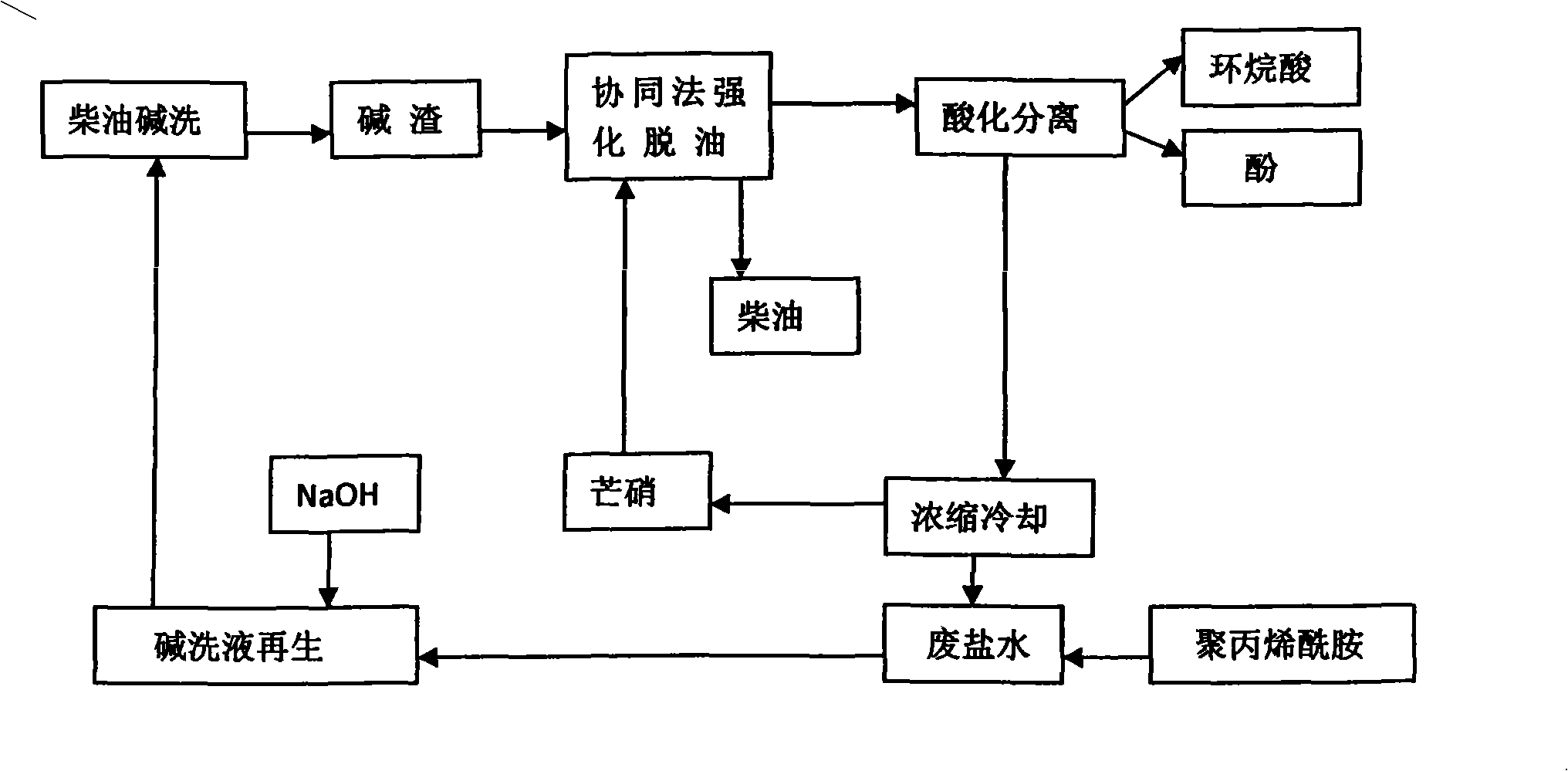

Image

Examples

Embodiment 1

[0034] Diesel soda residue contains 10% oil, 13% naphthenic acid, 5% creosote and 336700mg / l COD.

[0035] Add high-efficiency polymeric demulsifier, Glauber's salt and sulfuric acid to the diesel soda slag, the amount of demulsifier and Glauber's salt is 0.012% and 50% of the weight of the soda slag respectively, control the pH value at 7.0, stand for 2 hours to demulsify and separate Waste alkaline water and diesel oil. Control the temperature in a water bath, add 1 mol / L sulfuric acid to control the pH value at 5 when the waste alkaline water reaches 60°C, stir for 0.5 hours at a stirring speed of 500r / min, let stand in the separatory funnel for 2.5 hours to recover phenol, and use the same method Add 1 mol / L sulfuric acid to control the pH value at 3, let it stand for 2.5 hours to recover naphthenic acid, and separate the water phase. The aqueous phase is neutralized to neutral by adding NaOH, concentrated, cooled to 15°C, crystallized and filtered to obtain Glauber’s sal...

Embodiment 2

[0037] Diesel soda residue contains 10% oil, 13% naphthenic acid, 5% creosote and 336700mg / l COD.

[0038] Add high-efficiency polymeric demulsifier, Glauber's salt and sulfuric acid to the diesel soda slag, the amount of demulsifier and Glauber's salt is 0.010% and 60% of the weight of the soda slag respectively, control the pH value at 7.0, stand for 2 hours to demulsify and separate Waste alkaline water and diesel oil. Control the temperature in a water bath, add 1mol / L sulfuric acid to control the pH value at 6 when the waste alkaline water reaches 55°C, stir for 0.5 hours at a stirring speed of 500r / min, and let stand in a separatory funnel for 2.5 hours to recover phenol, use the same method Add 1 mol / L sulfuric acid to control the pH value at 4, let it stand for 2.5 hours to recover naphthenic acid, and separate the water phase. The aqueous phase is neutralized to neutral by adding NaOH, concentrated, cooled to 15°C, crystallized and filtered to obtain Glauber’s salt, ...

Embodiment 3

[0040] Diesel soda residue contains 10% oil, 13% naphthenic acid, 5% creosote and 336700mg / l COD.

[0041] Add high-efficiency polymeric demulsifier, Glauber's salt and sulfuric acid to the diesel soda slag, the amount of demulsifier and Glauber's salt is 0.015% and 70% of the weight of the soda slag respectively, control the pH value at 8.0, stand for 2 hours to demulsify and separate Waste alkaline water and diesel oil. Control the temperature in a water bath, add 1 mol / L sulfuric acid to control the pH value at 4 when the waste alkaline water reaches 50°C, stir for 0.5 hours at a stirring speed of 500r / min, let stand in a separatory funnel for 2.5 hours to recover phenol, and use the same method Add 1 mol / L sulfuric acid to control the pH value at 2, let stand for 2.5 hours to recover naphthenic acid, and separate the water phase. The aqueous phase is neutralized to neutral by adding NaOH, concentrated, cooled to 15°C, crystallized and filtered to obtain Glauber’s salt, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com