Method for testing alkyl quaternaries cationic surfactant

A surfactant and alkyl quaternary ammonium technology, which is applied in the detection field of alkyl quaternary ammonium cationic surfactants, can solve the problems of expensive detection instruments and poor qualitative results, and achieve cheap instruments and accurate analysis methods , the effect of little interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

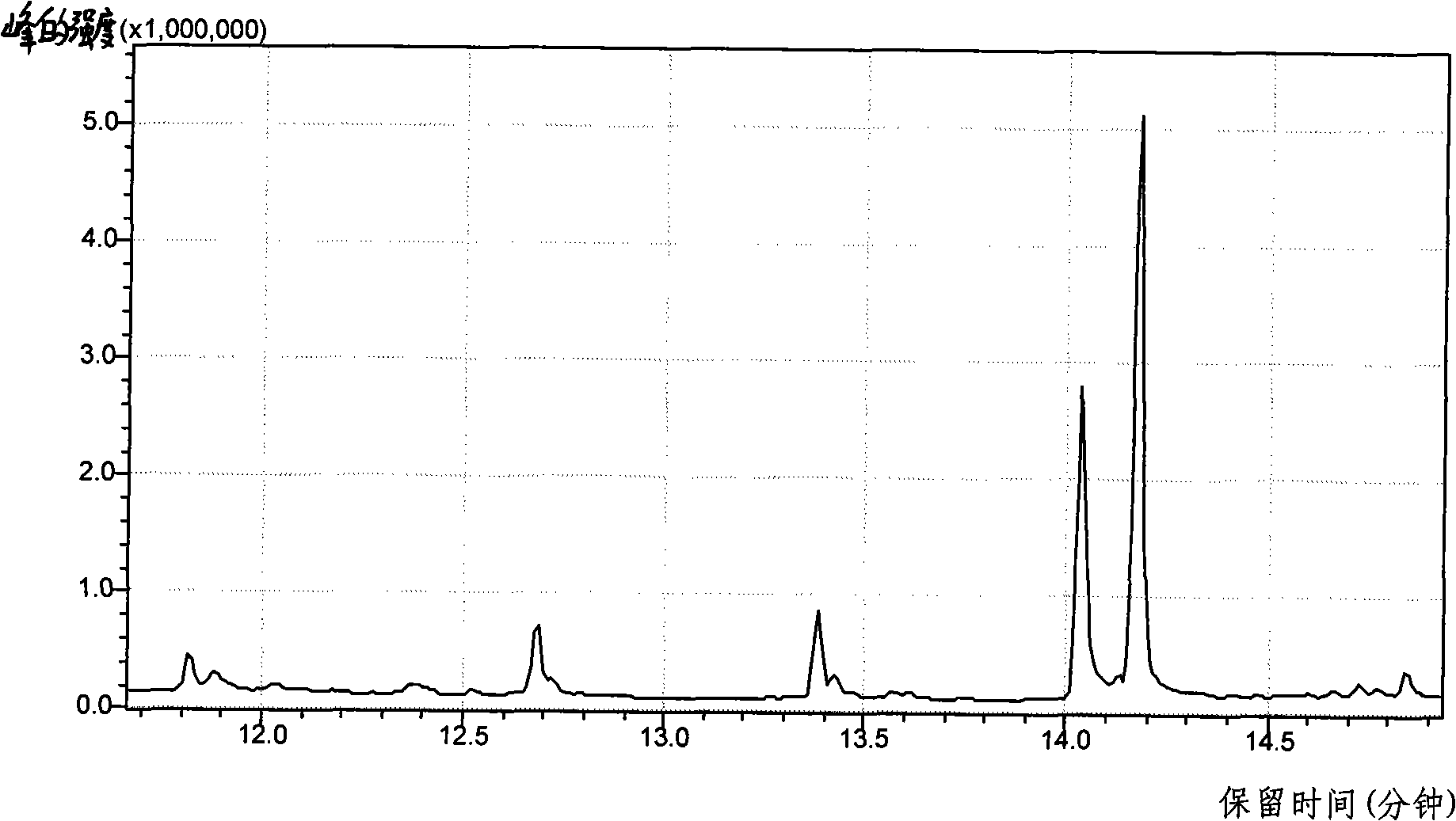

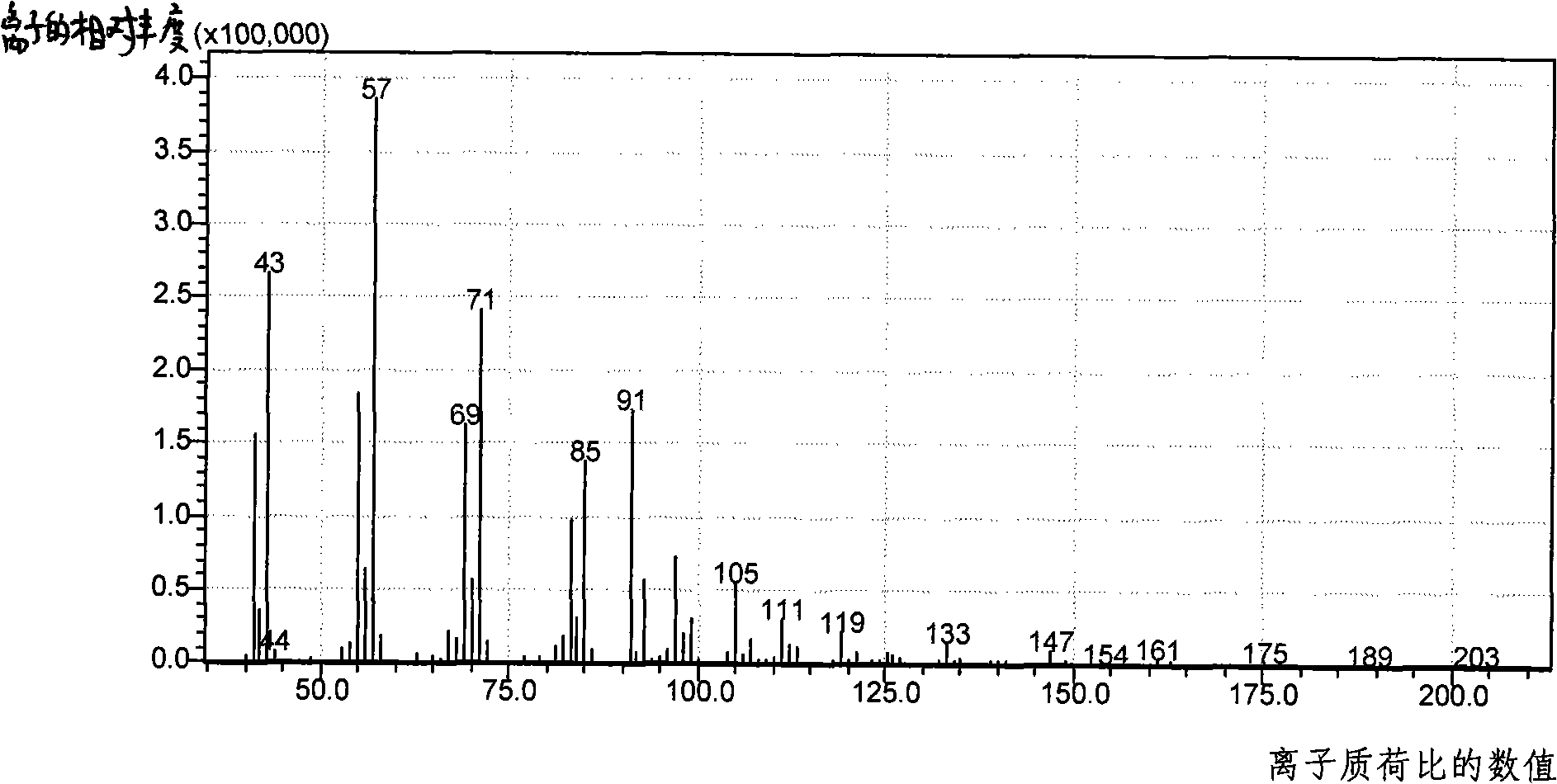

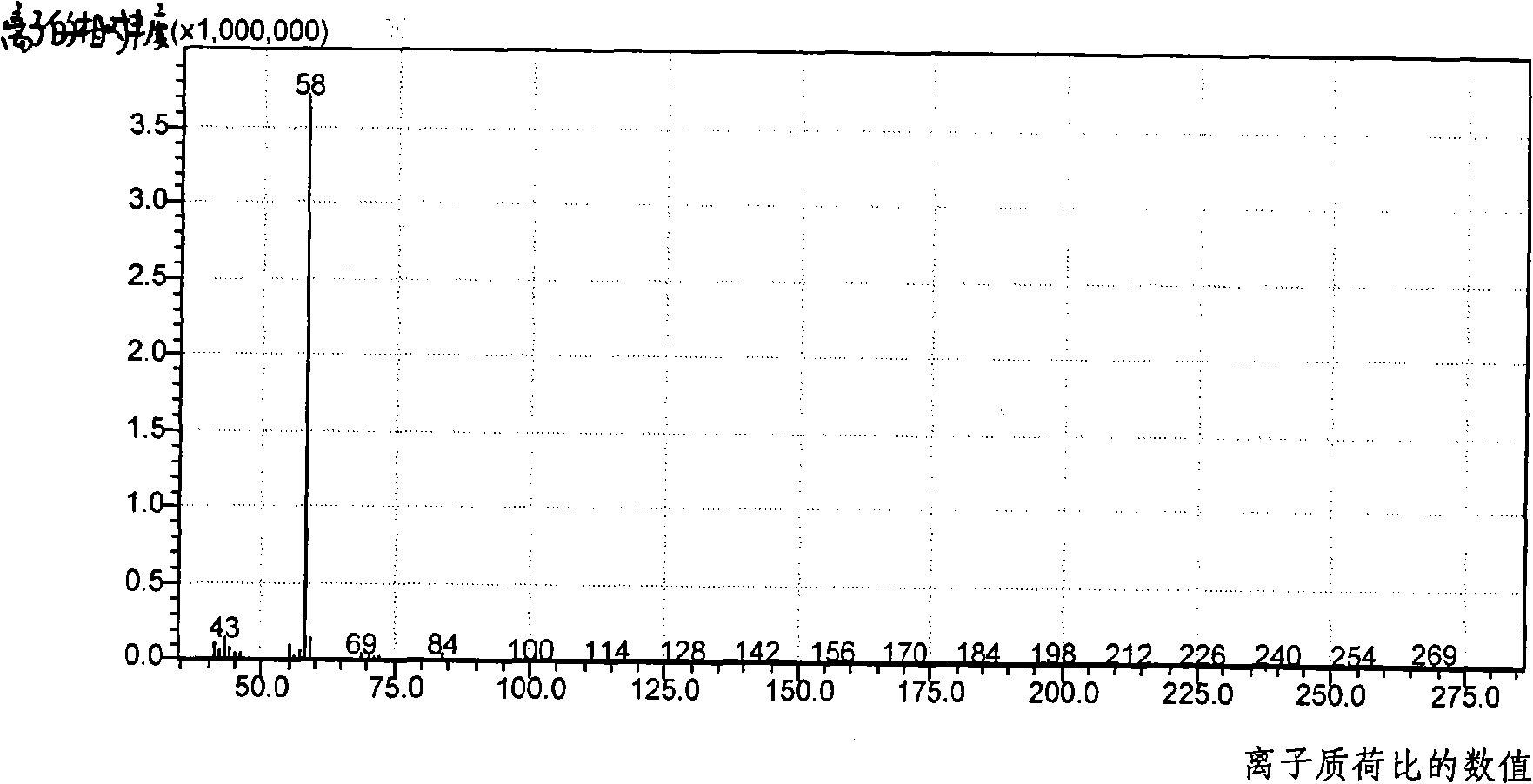

[0028] Using isopropanol as a solvent, a series of standard solutions of dioctadecyldimethylammonium chloride were prepared, and the gas chromatography-mass spectrometry GC-MS analysis and detection were carried out according to the above experimental conditions. The sample port temperature was set at 300°C; the interface temperature was set at 250°C; the carrier gas was helium, and the flow rate was 1 ml / min; Raise the temperature to 210°C and keep it for 2 minutes, then raise the temperature to 320°C at a speed of 20°C / min and keep it for 2 minutes; The source temperature was 250 °C; the injection volume was 1 microliter. Figure 1a It is the chromatogram of the detected dioctadecyldimethylammonium chloride decomposition product, the ordinate in the chromatogram represents the intensity of the peak, and the abscissa represents the retention time; Figure 1b It is the mass spectrogram of the detected dioctadecyldimethylammonium chloride decomposition product chlorooctadecane,...

Embodiment 2

[0030] Accurately weigh 0.5 g of the hair conditioner sample into a conical flask, add an appropriate amount of isopropanol into the round bottom flask, place it in an ultrasonic field, and conduct ultrasonic extraction at room temperature for 2 hours. Extract in this way three times, combine the extracts into a round-bottomed flask, concentrate the extracts by rotary evaporation, dilute to a 50 ml volumetric flask with isopropanol, take 10 ml, dry with anhydrous sodium sulfate, filter, and take the mother liquor for gas chromatography - Mass spectrometry test. Three parallel samples were made to this sample, the test numbers were A, B and C respectively, and the analysis results were shown in Table 1, and the first parallel sample (test number A) was measured 5 times, and the analysis results were shown in Table 2. Known from Table 1, the relative standard deviation (RSD) of parallel samples is 3.29%. Known from Table 2, the relative standard deviation of repeated tests is 0...

Embodiment 3

[0036] The standard solution in Example 1 was added to the hair conditioner sample in Example 2, and the experiment was carried out according to the above-mentioned sample pretreatment method and instrumental analysis and detection method. Four spiked levels were made to the sample, and the average value was obtained by three parallel measurements for each sample with the spiked content. According to the actual amount added and the measured results, the spiked recovery rate of the sample was calculated. The experimental results are shown in Table 3. It can be seen from Table 3 that the recovery rate of the samples was between 95% and 105%.

[0037] Table 3 The recovery of standard addition of this sample

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com