Method for synthesizing nano-scale oxide ceramic powder body

A nano-scale oxide and ceramic powder technology, which is applied in the field of ultra-fine nano-powder preparation, can solve the problems of high decomposition temperature, expensive equipment, and large particle size of nano-powder, and achieve high sintering activity, easier operation and control , The effect of lowering the decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation of Sodium Bismuth Titanate (Bi 0.5 Na 0.5 TiO 3 ) Nano powder

[0033] Select tetrabutyl titanate (Ti(OC 4 H 9 ) 4 ), bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), sodium nitrate (NaNO 3 ) Is a source of titanium, bismuth and sodium, and glycerol is used as a solvent.

[0034] 13.614g tetrabutyl titanate (Ti(OC 4 H 9 ) 4 ) After being diluted in 20mL of absolute ethanol, it is added dropwise to 40mL of glycerol, and stirred at room temperature to fully mix and dissolve. Weigh 9.7014g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), 1.6998g sodium nitrate (NaNO 3 ), adding to the above solution in sequence, heating to 40°C, and stirring vigorously at the same time to fully dissolve, and obtaining metal salt solution A. Weigh 21.6g of sugar and dissolve it into solution A, adjust the temperature of the solution to 60°C, and stir vigorously at the same time to fully dissolve the sugar. After obtaining a yellow viscous liquid, weigh 1.6008g of ammonium nitrate (NH 4 NO 3 )...

Embodiment 2

[0035] Example 2 Preparation of titanium dioxide nanopowder (organic solvent)

[0036] Tetrabutyl titanate was selected as the titanium source, and absolute ethanol was used as the solvent.

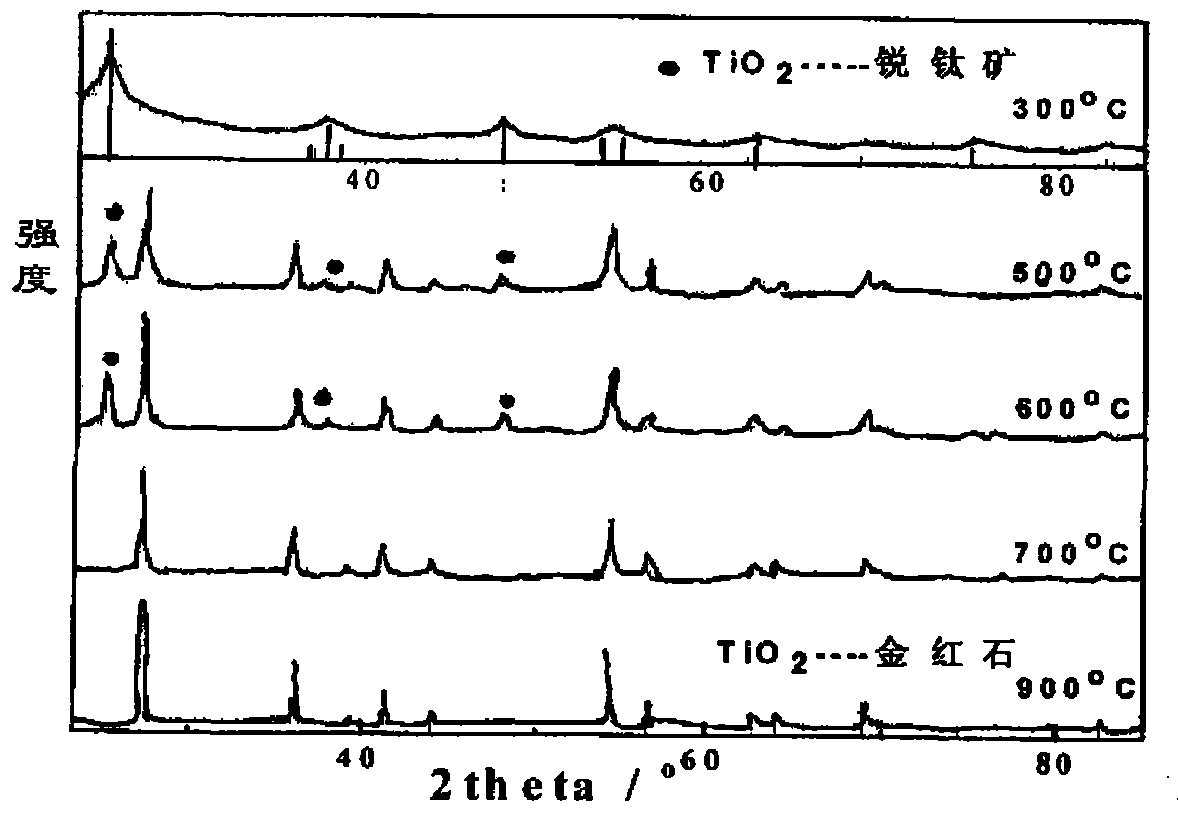

[0037] Dilute 17 g of tetrabutyl titanate in 40 mL of absolute ethanol at room temperature to obtain solution A, add 27 g of sugar to solution A, adjust the temperature to 60° C., stir vigorously to make the solution fully dissolved. After obtaining a yellow viscous liquid, weigh 2g of ammonium nitrate (NH 4 NO 3 ), stir to dissolve. The resulting solution was dried at 69°C for 4 hours to remove most of the solvent, and then transferred to a 190°C drying oven for 24 hours. The powder synthesis is carried out at 300℃, 500℃, 600℃, 700℃ and 900℃ respectively for 2-6 hours.

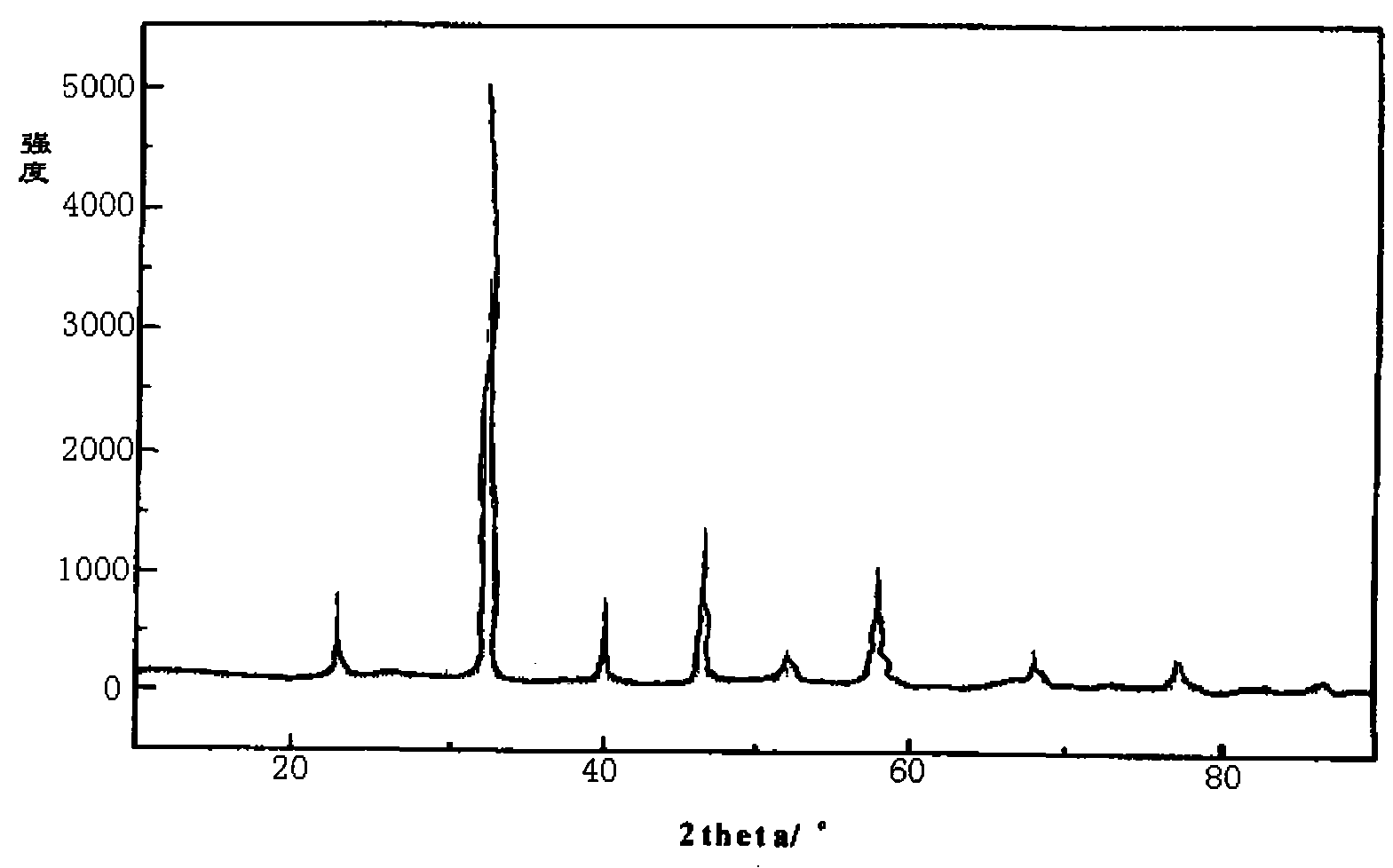

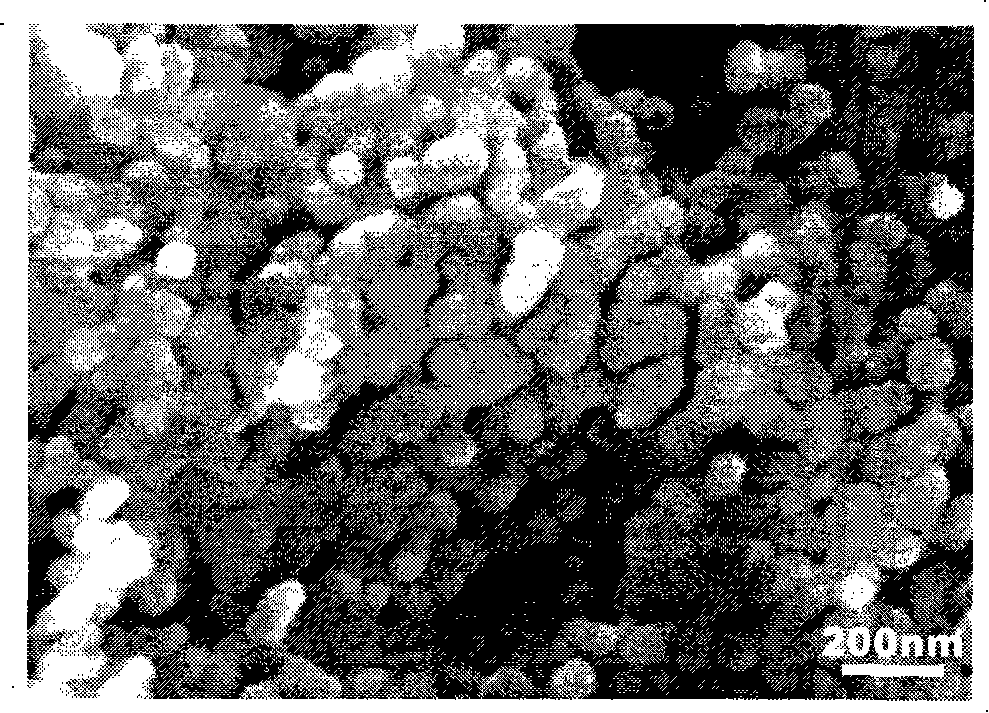

[0038] Such as image 3 , 4 As shown, XRD characterization shows that a pure anatase phase is formed at 300°C, a pure rutile phase is formed at 700°C, and two phases coexist at the two temperature points in the middle. XRD p...

Embodiment 3

[0039] Example 3 Preparation of titanium dioxide nanopowder (water)

[0040] Titanium tetrachloride stabilized with alcohols (TiCl 4 ) As the titanium source, deionized water is used as the solvent.

[0041] Dissolve 380 g of titanium tetrachloride in 400 mL of absolute ethanol to obtain 548 g of stable titanium tetrachloride solution. Weigh 2.73582 g of the above stable solution, and dissolve it in 10 mL of deionized water at room temperature to obtain solution A. Weigh 10.8g of sugar, add to liquid A and stir to dissolve. Weigh 1g of ammonium nitrate (NH 4 NO 3 ), stir to dissolve. The resulting solution was first dried at 105°C for 4 hours to remove most of the solvent, and then transferred to a drying oven at 190°C for 24 hours. Pre-fired at 300℃, 500℃, 700℃ and 900℃ for 6h for powder synthesis.

[0042] Such as Figure 5 , 6 As shown, the XRD structure analysis shows that a well-crystallized anatase phase can be obtained at 300°C and 500°C, a pure rutile phase is formed at 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com