Dual-layer composite soft plastic foaming plate and molding method thereof

A foamed sheet, double-layer composite technology, applied in the field of materials, can solve the problems of high structural requirements, harsh conditions, rarely used, etc., and achieve the effects of simple process, short production cycle, excellent comprehensive functions and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

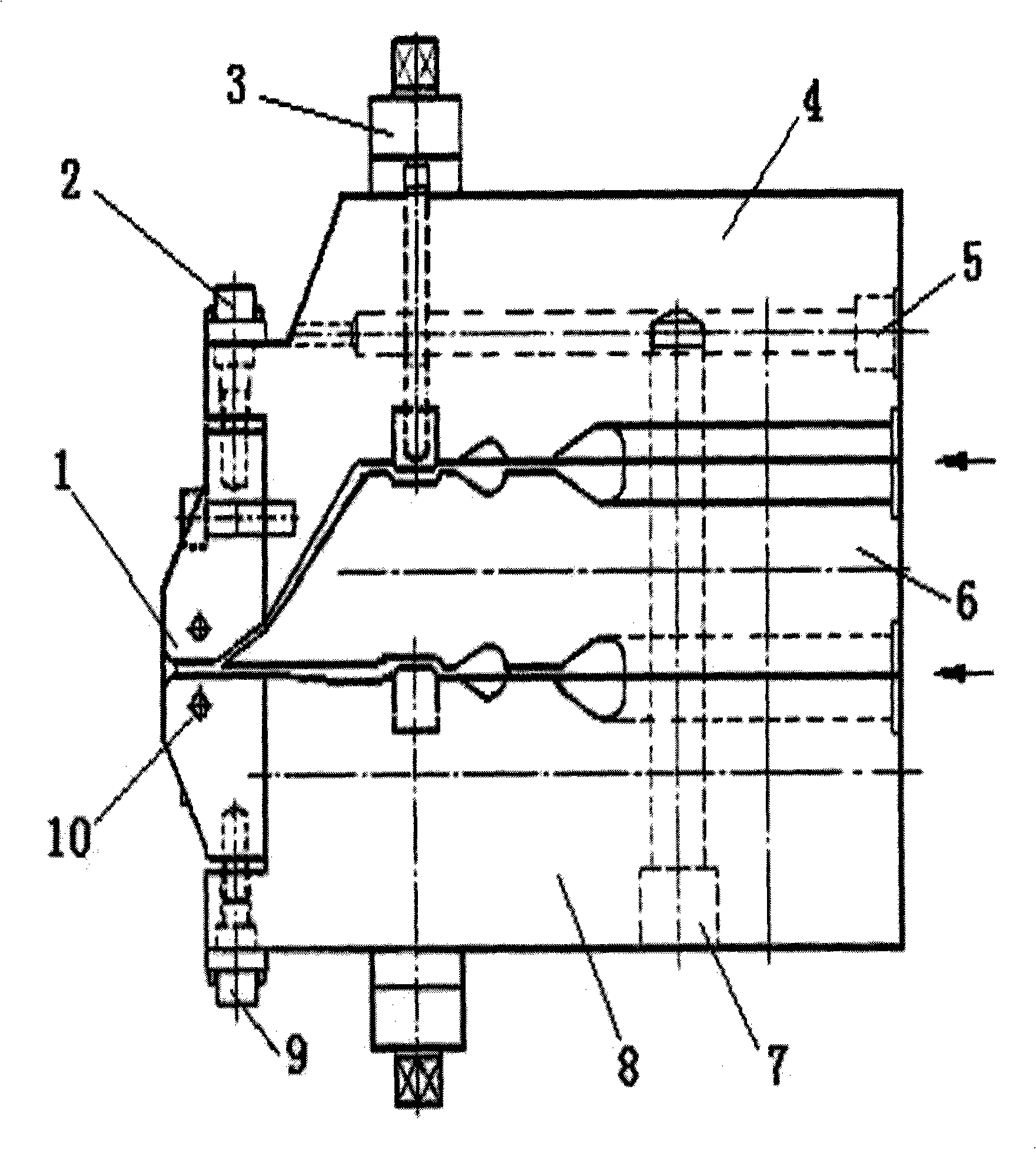

Method used

Image

Examples

Embodiment 1

[0061] The processed double-layer composite soft-faced plastic foam board has a width of 100 mm and a thickness of 7 mm, of which the soft face layer is 4 mm and the hard bottom layer is 3 mm. The formula is as follows:

[0062] Hard bottom layer formula: (both are weight ratio)

[0063] Polyvinyl chloride resin SG-7 type 100 parts Acrylic flow modifier ACR401 2 parts

[0064] Ca / Zn composite heat stabilizer 4 parts Acrylate lubricant modifier K175 0.5 part

[0065] Foaming agent AC-410 0.1 parts Active light calcium carbonate 8 parts

[0066] Cell regulator ACR530 5 parts

[0068] Polyvinyl chloride resin 2500 type 100 parts stearic acid 0.4 parts

[0069] Calcium-zinc composite heat stabilizer 4 parts paraffin wax 0.2 parts

[0070] Foaming agent AC-410 0.2 parts Antimony trioxide 5 parts

[0071] Dioctyl phthalate 80 parts Active light calcium carbonate 5 parts

[0072] Dioctyl sebacate 20 parts Phthalocyanine blue 0.001 parts

[0073]...

Embodiment 2

[0083] The width of the double-layer composite soft-faced plastic foam board is 300mm and the thickness is 9mm, of which the soft surface layer is 5mm and the hard bottom layer is 4mm. The recipe is the same as Example 1, and the process parameters are set as follows:

[0084] Hard bottom layer: single-screw extruder, screw diameter 90mm, aspect ratio 25, compression ratio 3:1. The barrel heating zone 1 is 160°C, the second zone is 185°C, the third zone is 173°C, the fourth zone is 187°C, and the fifth zone is 155°C.

[0085] Soft surface layer: single-screw extruder, screw diameter 105mm, aspect ratio 25, compression ratio 3.8:1. The barrel heating zone 1 is 160°C, the second zone is 175°C, the third zone is 173°C, the fourth zone is 177°C, and the fifth zone is 155°C.

[0086] Mold temperature setting:

[0087] The connecting pipe of the hard bottom layer is 155°C, the connecting pipe of the soft surface layer is 160°C, the connector is 160°C, the upper and lower layers o...

Embodiment 3

[0092] The width of the processed and formed double-layer composite soft plastic foam board is 1220 mm, and the thickness is 7 mm, of which the soft layer is 4 mm and the hard layer is 3 mm. The formula is basically the same as the example one. The process is set as follows:

[0093] Hard bottom layer:

[0094] Φ80 / 156mm conical twin-screw extruder with a power of 75 kilowatts.

[0095] The temperature setting is: barrel heating zone 1 190°C, heating zone 2 185°C, heating zone 3 173°C, heating zone 4 167°C, heating zone 5 (merging cone) 155°C, heating zone 6 (connecting pipe) 150°C, The screw oil temperature is 100°C.

[0096] Soft Surface:

[0097] Φ80 / 156mm conical twin-screw extruder with a power of 75 kilowatts.

[0098] The temperature setting is: barrel heating zone 1 190°C, heating zone 2 178°C, heating zone 3 175°C, heating zone 4 170°C, heating zone 5 (merging cone) 165°C, heating zone 6 (connecting pipe) 155°C, The screw oil temperature is 100°C.

[0099] Mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com