Treatment apparatus for organic wastewater

A treatment device, an organic technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of insufficient flow, increased aeration power, and reduced biological activity To reduce the quality of biological metabolites, reduce the frequency of resin regeneration, and improve the quality of treated water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

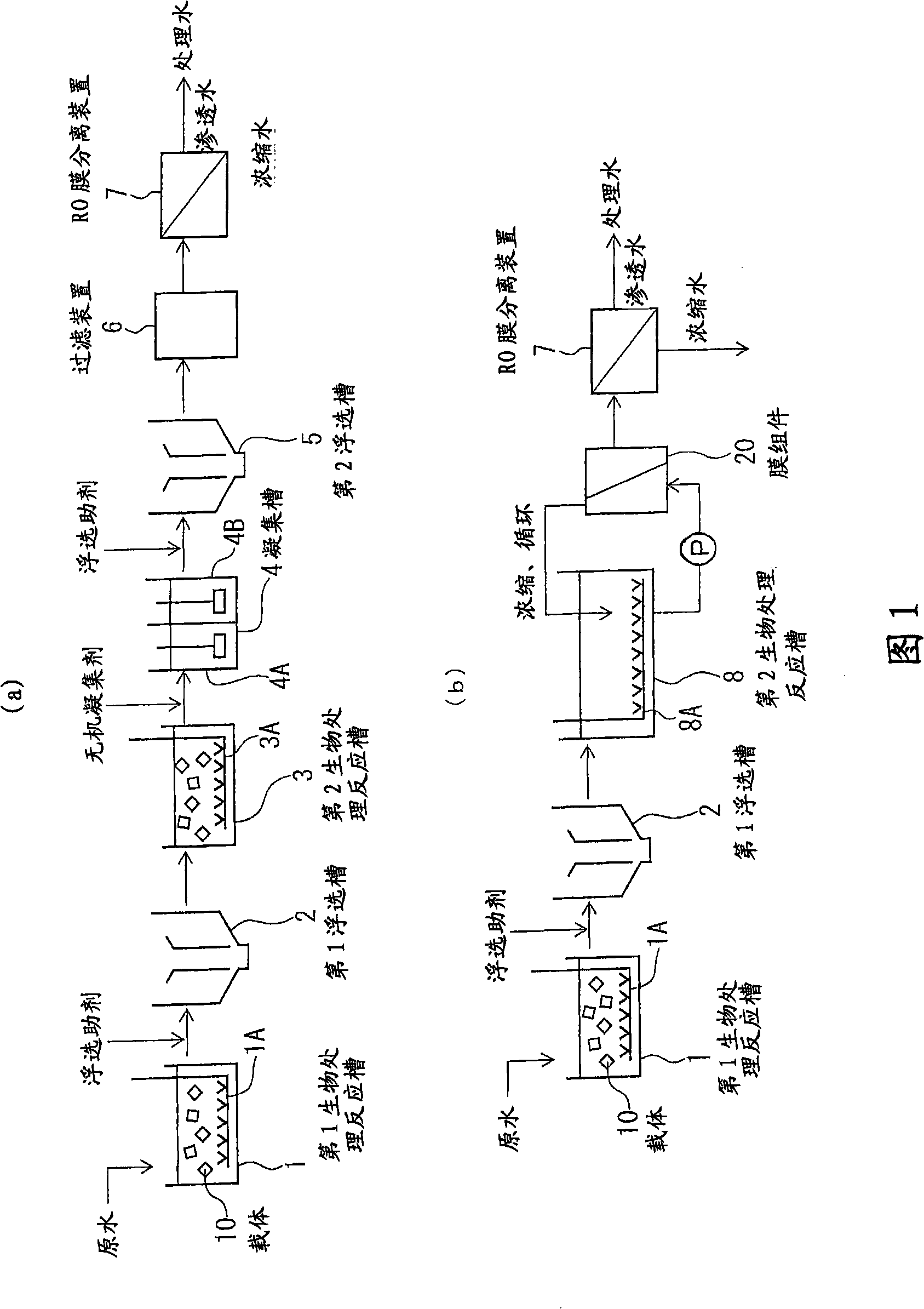

[0116] In the device shown in FIG. 1( a ), factory effluent of the following water quality whose main component is tetramethylammonium hydroxide (TMAH) is used as raw water, and the treated water volume is 2000 L / day. In addition, since the amount of phosphorus was presumed to be insufficient in the biological treatment of this raw water, phosphoric acid was added to raw water so that TOC:P=100:3, and it treated. In addition, potassium oleate was used as a flotation aid.

[0117]

[0118] S-TOC: 328mg / L

[0119] Kj-N: 76mg / L

[0120] PO 4 -P: 0.8mg / L

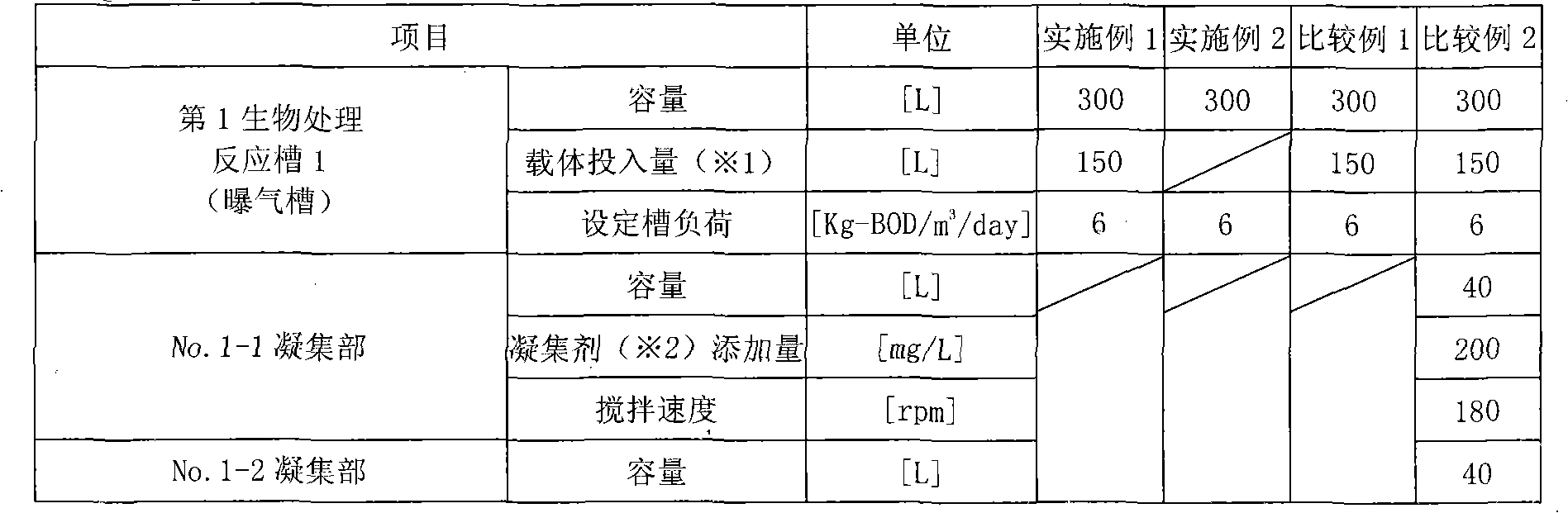

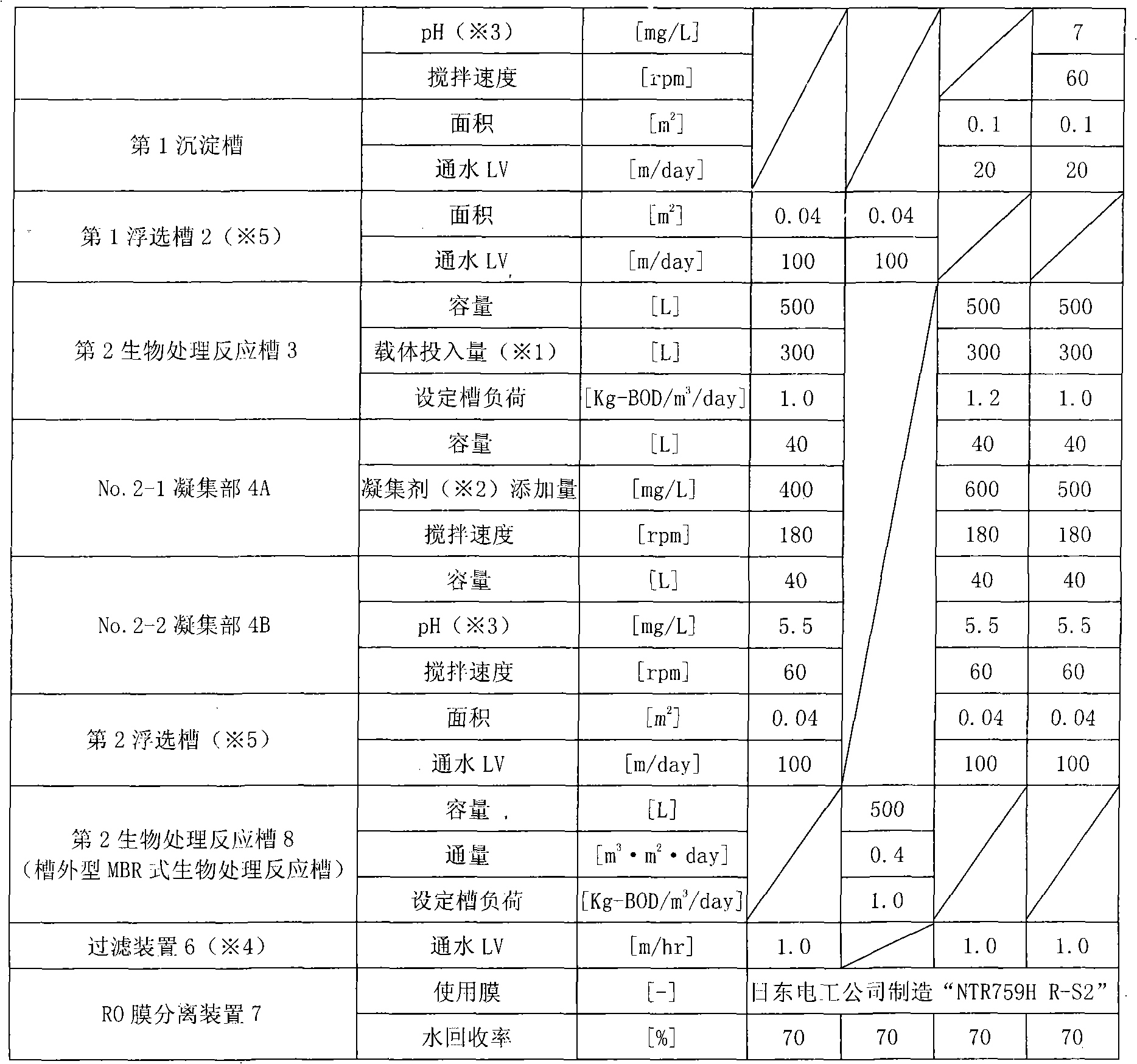

[0121] Table 1 shows the specifications and processing conditions of the equipment used.

[0122] In addition, Table 2 shows the water quality of each part, and Table 3 shows the specific gravity of the carrier added to the first and second biological treatment reaction tanks.

Embodiment 2

[0124] In the device shown in Fig. 1(b), the same as the treatment in Example 1, the factory effluent was used as raw water and treated with a treatment water volume of 2000 L / day. In addition, since the amount of phosphorus was presumed to be insufficient in the biological treatment of the raw water, phosphoric acid was added to the raw water so that TOC:P=100:3, and the treatment was performed. As a flotation aid, potassium oleate was used in the same manner as in Example 1.

[0125] Table 1 shows the specifications and processing conditions of the equipment used.

[0126] In addition, Table 2 shows the water quality of each part, and Table 3 shows the specific gravity of the carrier added to the first biological treatment reaction tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com