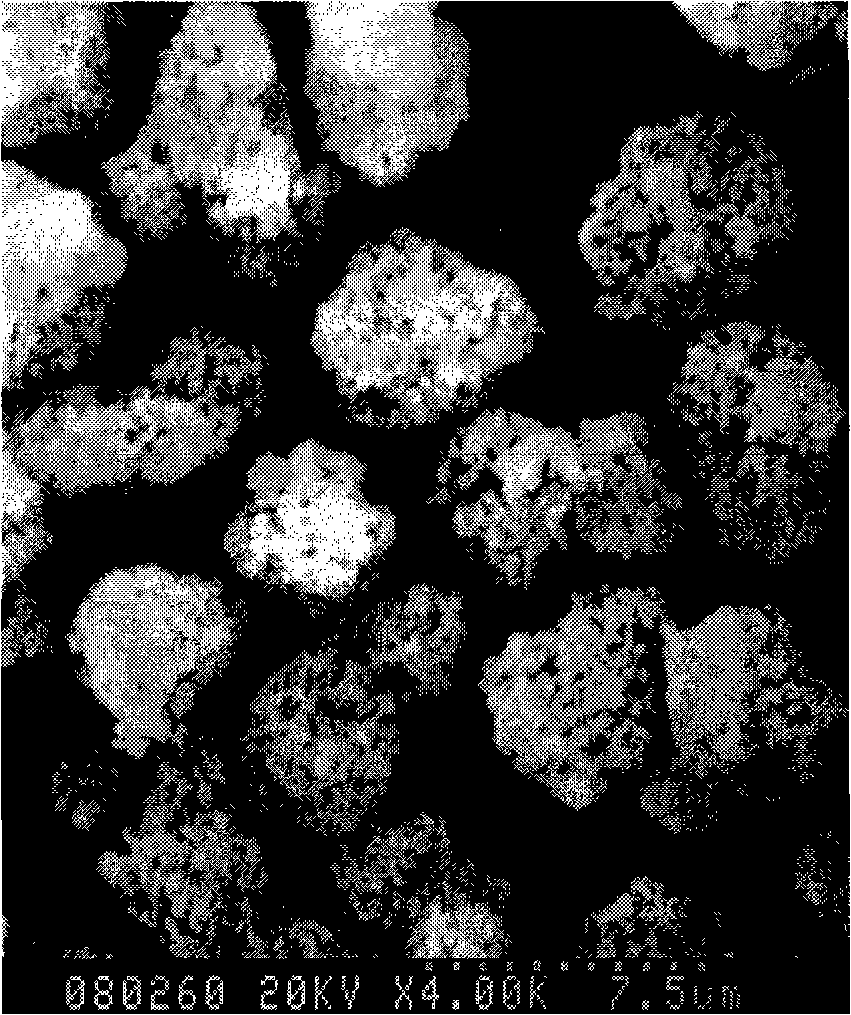

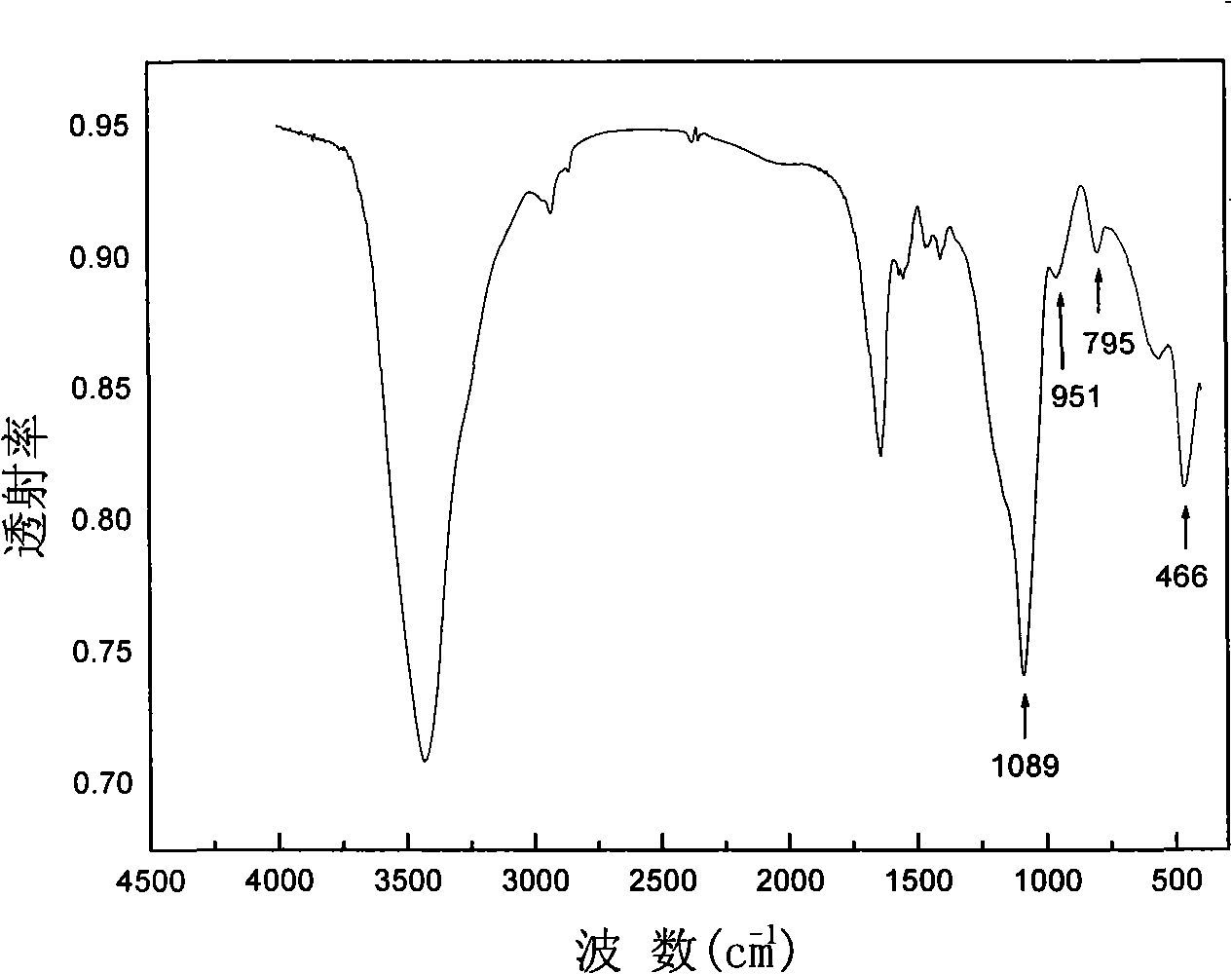

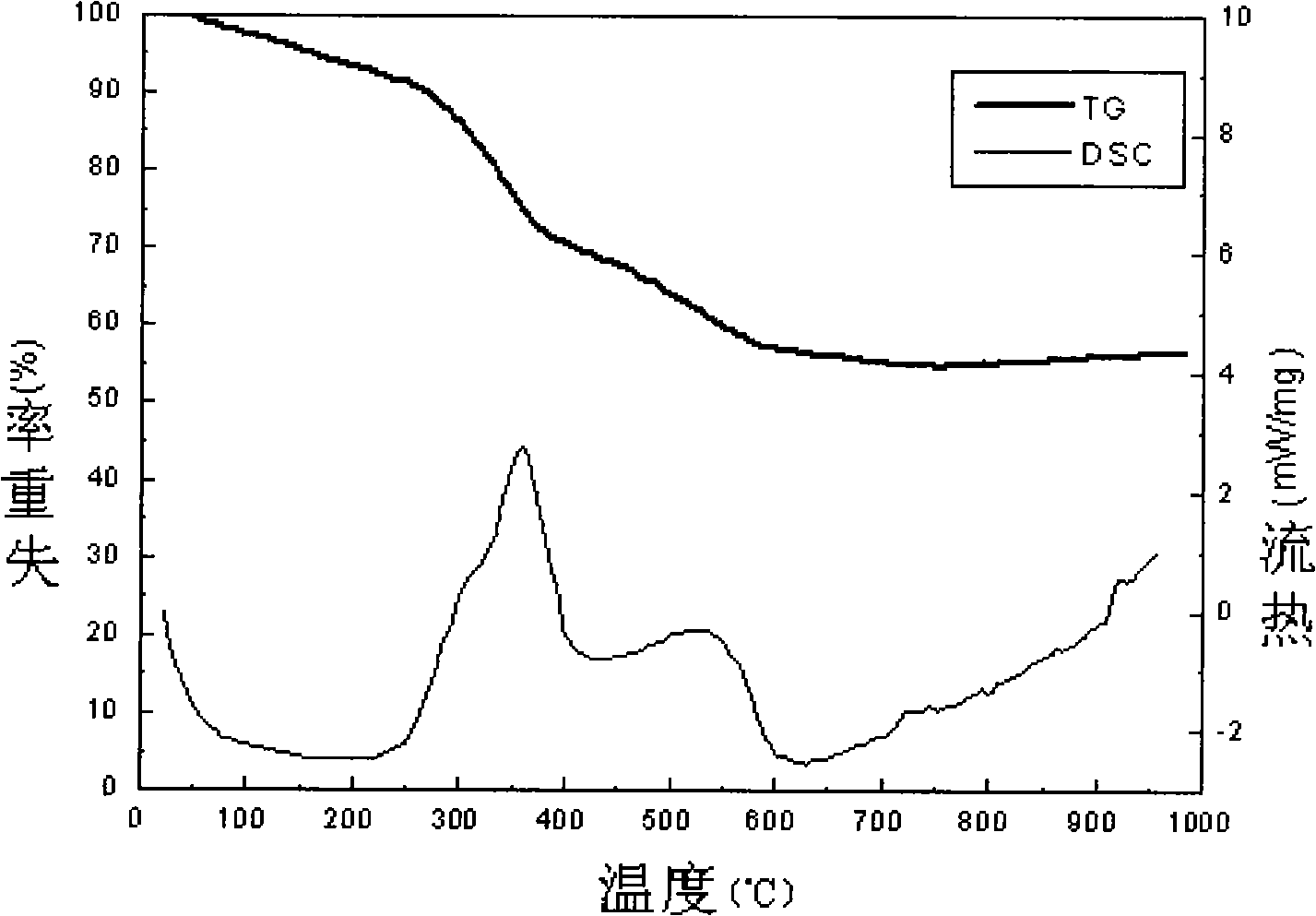

Porous magnetic gelatine microsphere and preparation thereof

A technology of gelatin and microspheres, which is applied in the field of functional polymer materials and organic-inorganic composite materials, can solve problems such as toxicity, unfavorable applications, and restrictions, and achieve the effects of high mechanical stability, uniform size, and large selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The proportioning by weight of its raw material components is as follows:

[0030] Ammonia 100 parts

[0031] Magnetic particles 12 parts

[0032] 20 parts gelatin

[0033] Liquid paraffin 1400 parts

[0034] 12 parts of water-soluble emulsifier

[0035] Oil-soluble emulsifier 64 parts

[0036] TEOS 100 copies

[0037] Mix the ammonia solution, nano-magnetic particles, water-soluble emulsifier, and gelatin evenly according to the proportions of the above components, seal and soak for 3 hours. Heat and stir in a water bath at 60°C to completely dissolve the gelatin to form liquid A as the water phase.

[0038] In another three-necked flask equipped with a stirrer, add liquid paraffin dissolved with an emulsifier according to the above ratio, and stir evenly in a water bath at 60°C to form liquid B as the oil phase.

[0039] Slowly add liquid A to liquid B dropwise under rapid mechanical stirring, and continue stirring after the dropwise addition is complete. Afte...

Embodiment 2

[0041] The proportioning by weight of its raw material components is as follows:

[0042] Ammonia 100 parts

[0043] Magnetic particles 15 parts

[0044] 15 parts gelatin

[0045] Liquid paraffin 1400 parts

[0046] Water-soluble emulsifier 0 parts

[0047] Oil-soluble emulsifier 64 parts

[0048] TEOS 100 copies

[0049] Mix the ammonia solution, nano-magnetic particles, and gelatin evenly according to the proportions of the above components, seal and soak for 4 hours. Heat and stir in a water bath at 65°C to completely dissolve the gelatin to form liquid A as the water phase.

[0050] In addition, add the liquid paraffin dissolved with the oil emulsifier in the above ratio into a three-necked flask equipped with a stirrer, and stir in a water bath at 65°C to form B liquid as the oil phase.

[0051]Slowly add liquid A into liquid B dropwise under fast mechanical stirring, and increase the stirring speed rapidly after the dropwise addition is completed. After emulsific...

Embodiment 3

[0053] The proportioning by weight of its raw material components is as follows:

[0054] Ammonia 100 parts

[0055] Magnetic particles 20 parts

[0056] 25 parts gelatin

[0057] Liquid paraffin 1600 parts

[0058] 10 parts of water-soluble emulsifier

[0059] Oil-soluble emulsifier 74 parts

[0060] 60 servings of TEOS

[0061] Mix the ammonia solution, nano-magnetic particles, water-soluble emulsifier, and gelatin evenly according to the proportions of the above components, seal and soak for 3 hours. Heat and stir in a water bath at 60°C to completely dissolve the gelatin to form liquid A as the water phase.

[0062] In addition, add the liquid paraffin dissolved with the oil emulsifier according to the above ratio into a three-neck flask equipped with a stirrer, and stir in a water bath at 60°C to form B liquid as the oil phase.

[0063] Slowly add liquid A into liquid B dropwise under fast mechanical stirring, and increase the stirring speed rapidly after the dropw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com