Anatase titanium dioxide type titanium white pulp and preparation thereof

An anatase-type titanium dioxide and anatase-type technology, applied in chemical instruments and methods, pigment slurry, inorganic pigment treatment, etc., can solve the problems of high viscosity of dispersion slurry, poor dispersion, and stable dispersion of pigments, etc., to achieve Wide range of raw material sources, low raw material cost, obvious social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] The preparation method of the anatase titanium dioxide slurry provided in this specific embodiment intends to prepare the anatase titanium dioxide slurry with a pigment mass percentage between 65% and 70% and a low viscosity.

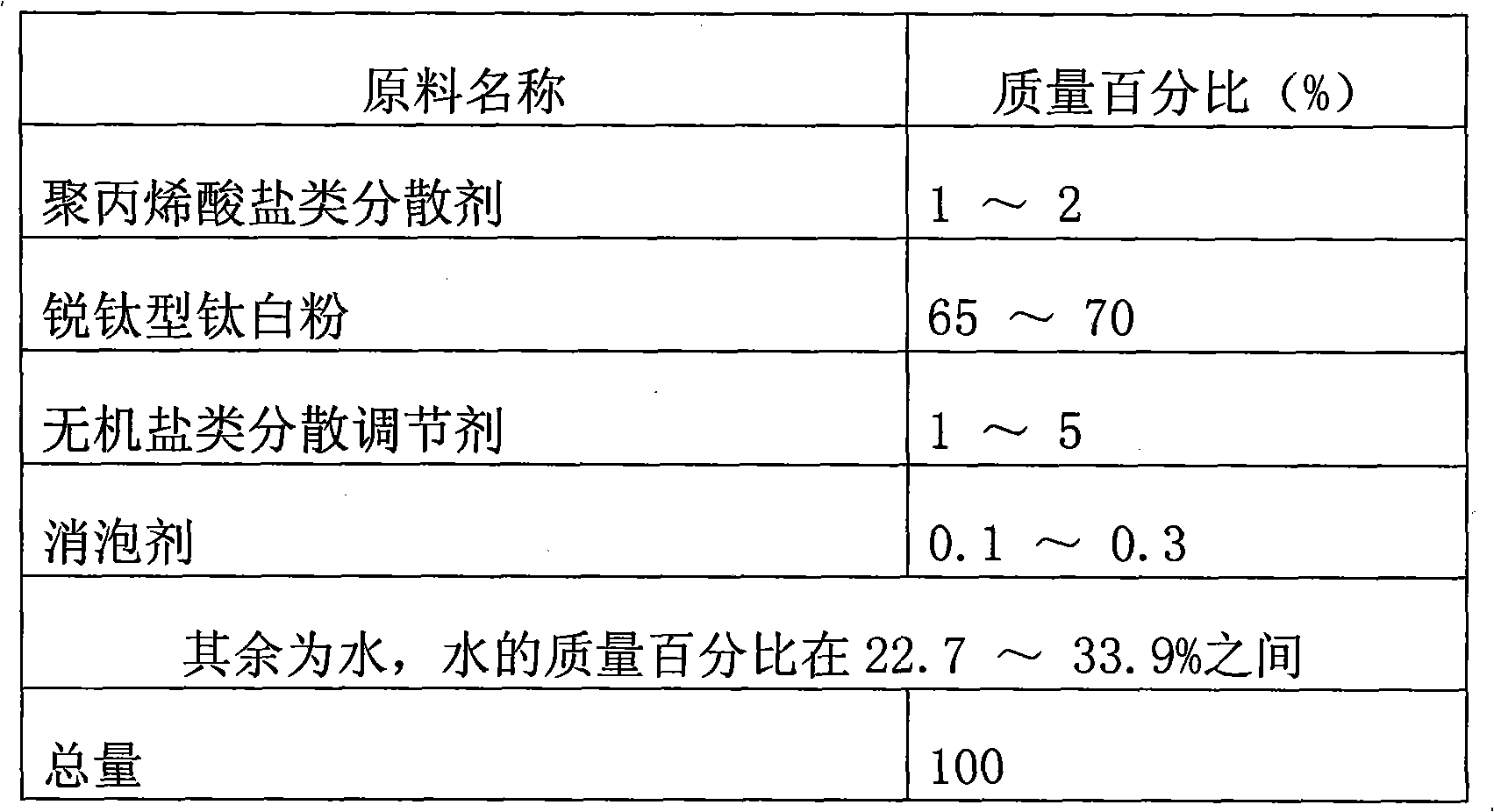

[0029] The production formula of the anatase type titanium white slurry prepared by the present invention is as follows:

[0030]

[0031] The polyacrylate salt dispersant mentioned in the formula of the present invention is sodium polyacrylate used in this specific method, and the mass percentage of its active ingredient is 38-43%, which is a kind of high-efficiency and low-cost pigment and filler dispersant It has a good dispersion and stabilization effect on pigments and fillers of water-based paints.

[0032] The anatase titanium dioxide in the formula of the present invention is non-surface-treated, the anatase titanium dioxide used for coatings, and its technical index meets the GB / T 1706-2006 standard.

[0033] The inorganic salt dispe...

specific Embodiment approach 2

[0041] This specific embodiment is basically the same as the steps included in the formula and preparation method of specific embodiment 1, the difference is:

[0042] In the step of preparation before dispersion in this specific embodiment, the added sodium polyacrylate is 1 kg, the defoamer is 0.05 kg, and the water is 24.7 kg. The inorganic salt dispersion regulator that adds in the low-speed dispersion step is 5 kilograms, comprises the calcium silicate powder of 3 kilograms and the magnesium carbonate powder of 2 kilograms. The added anatase type titanium dioxide is 70 kg. The low speed dispersion time was 15 minutes. The amount of defoamer added in subsequent processing steps was 0.25 kg.

specific Embodiment approach 3

[0043] This specific embodiment is basically the same as the steps included in the formula and preparation method of specific embodiment 1, the difference is:

[0044] In the step of preparation before dispersion in this specific embodiment, the added sodium polyacrylate is 2 kg, the defoamer is 0.2 kg, and the water is 28.7 kg. The inorganic salt dispersion regulator that adds in the low-speed dispersion step is 4 kilograms, comprises the calcium carbonate powder of 1 kilogram and the magnesium silicate powder of 3 kilograms. The added anatase type titanium dioxide is 65 kilograms. The low speed dispersion time was 10 minutes. The amount of defoamer added in subsequent processing steps was 0.1 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com