Microflow control chip used for ultraviolet-visible absorption detection and preparation thereof

A microfluidic chip and chip technology, applied in the field of biochemical analysis, can solve problems such as high cost and complicated operation process, and achieve the effects of convenient operation, simple process, and reduced process difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

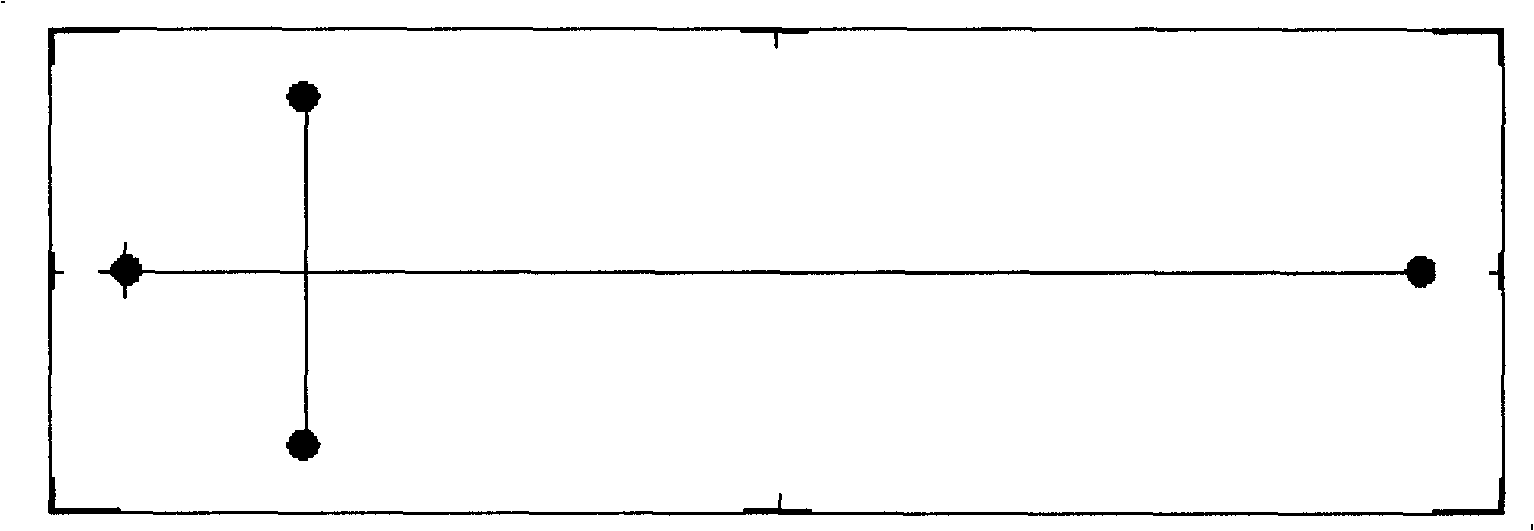

[0031] 1. Combine figure 1 , the shape of the middle channel is a simple straight channel form. Firstly, the plexiglass is processed into the required chip size (25*50mm 2 ), ultrasonically clean the surface with deionized water;

[0032] 2. Combine figure 2 , using a CNC milling machine to process straight channels, using the instrument on the chip 1 to control the lateral displacement on the X axis, the longitudinal displacement on the Y axis, and the scribe depth on the Z axis. The channel is 50 μm deep and 100 μm wide;

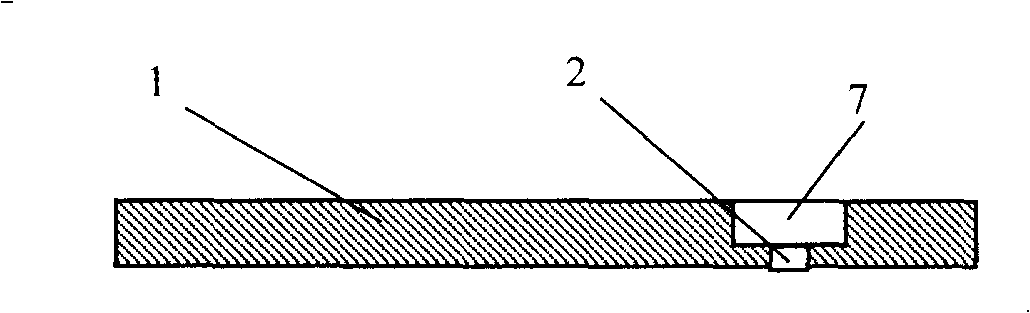

[0033] 3. After processing and manufacturing the channel, punch holes on the chip 1 as the sample pool, buffer sample pool, waste liquid pool, and sample recovery pool; and open the detection window 3 at the detection position for mounting slides and increasing absorption Optical path: First use a drill with a radius of 0.25mm to get through the test hole 2, and then use a milling cutter with a radius of 0.5mm to mill out 3×3mm 2 The square groove 7 ha...

Embodiment 2

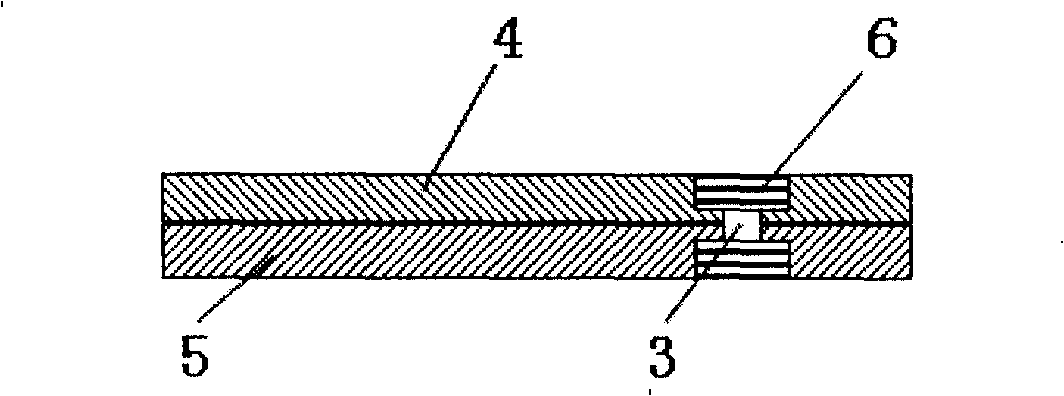

[0038] combine Figure 3-Figure 4 , the shape of the channel in this embodiment is a curved channel form with a curved corner shape, and the processing process is basically the same as in Example 1, only the channel scribing program is changed accordingly during the channel processing process.

[0039] 1. First process the plexiglass into the required chip size (30*30mm 2 ), ultrasonically clean the surface with deionized water;

[0040] 2. Use the CNC milling machine to process the curved groove, and control the turning radius and position of the groove through the corresponding program;

[0041] 3. After processing and manufacturing the channel, punch holes on the chip as the sample pool, buffer sample pool, waste liquid pool, and sample recovery pool; and open the detection window at the detection position to prepare for mounting slides and increase the absorption light path : First use a drill with a radius of 0.25mm to open it, and then use a milling cutter with a radiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com