Method for measuring organic acid and ester of centrifuge waste water in cis-anhydride production process with liquid phase chromatography

A production process and liquid chromatography technology, applied in the field of chemical analysis, can solve problems such as difficult accurate quantification, inability to measure at the same time, low solubility, etc., and achieve the effect of simple determination method, good reproducibility and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] (1) Preparation of standard sample solution

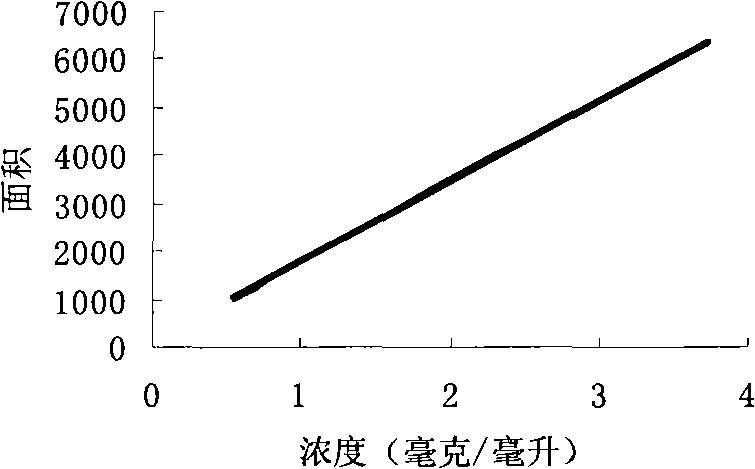

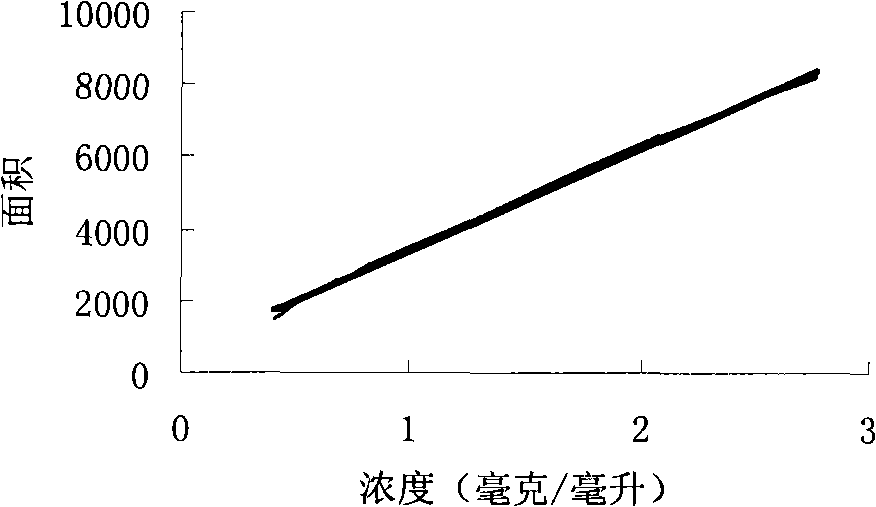

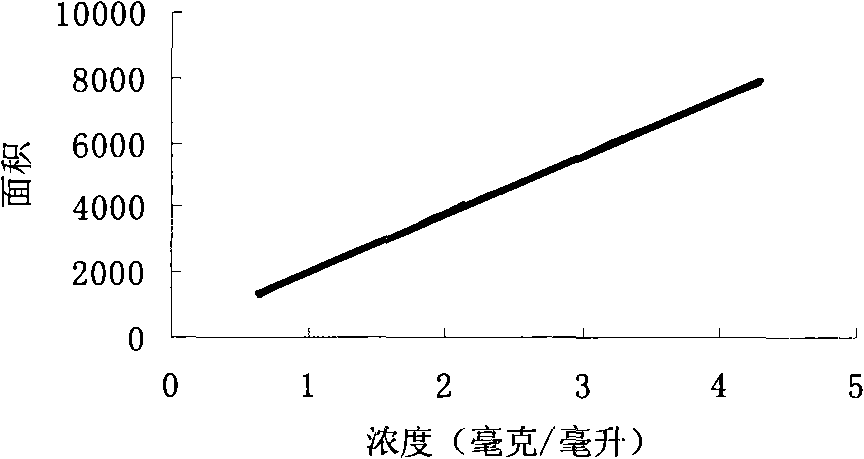

[0026] Weigh 0.01 g (accurate to ±0.0001 g) of standard substances of maleic acid, fumaric acid, phthalic acid and dibutyl phthalate, respectively, and prepare 4 to 5 standards with different concentrations. solution, set aside. In order to ensure that the detection signal is within the optimal response value range of the instrument (20%-80% of full scale), the concentration range of the standard sample solution in this experiment is 0.05-5 mg / ml.

[0027] (2) Chromatographic analysis conditions

[0028] Instrument and chromatographic column: Agilent HP1090 or Shimadzu SCL-10AVP liquid chromatograph, matching diode array detector and data processing system, Agilent C18 chromatographic column.

[0029] Mobile phase: water / methanol / ethyl acetate were mixed at an initial mass ratio of 10 / 20 / 70, and gradient elution was adopted.

[0030] Raw materials: methanol (chromatographically pure), ethyl acetate (chromatographically pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com