Preparing method of WMo mineral carbon composited anode target material for X ray tube with great power

A composite anode and high-power technology, applied in X-ray tube electrodes, X-ray tube parts, X-ray equipment, etc., can solve the problem of low heat dissipation efficiency and achieve the effect of strong heat dissipation, high melting point and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

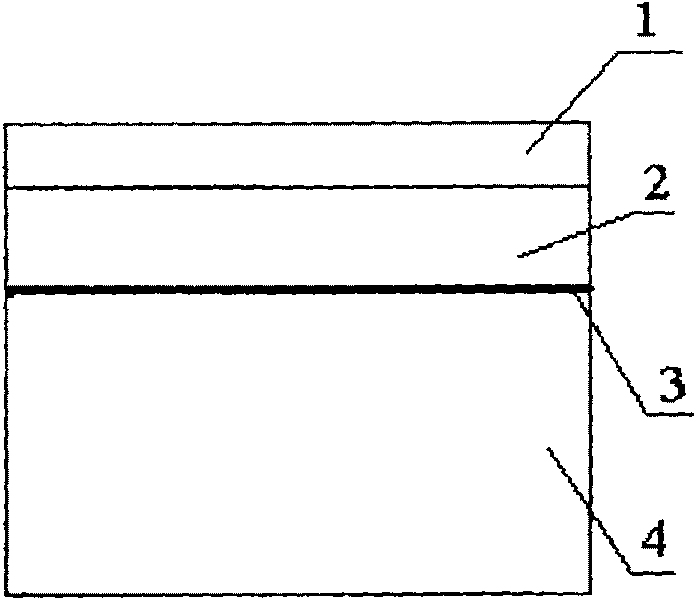

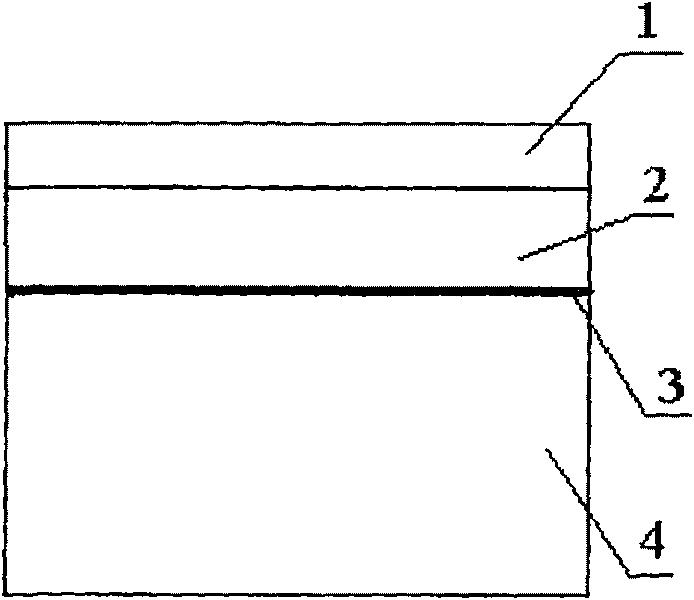

[0050] Prepare a W / Mo / graphite composite target with a diameter of 20mm and a height of 48mm, in which the thickness of the tungsten layer is 2mm, the thickness of the molybdenum layer is 6mm, and the thickness of the graphite layer is 40mm (including a bonding layer thickness of 0.1mm).

[0051] According to the formula m=ρπr 2 h, respectively calculate the mass of tungsten powder and molybdenum powder. Take 16.16 grams of tungsten powder with a purity of 99.5% and a particle size of 1 μm to 6 μm, calculate and take 0.10 ml of glycerol of analytical purity according to the mass volume ratio of tungsten powder 5ml / kg, and put the above raw materials into the mixer Within 6 hours, after mixing evenly, sieve with a 40-mesh sieve to obtain tungsten powder. Take 19.26 grams of molybdenum powder with a purity of 99.5% and a particle size of 1 μm to 6 μm, calculate and take 0.08 ml of glycerol with analytical purity according to the mass volume ratio of 5 ml / kg to the molybdenum po...

Embodiment 2

[0053] Prepare a W / Mo / graphite composite anode target with a diameter of 60mm and a height of 40mm, wherein the thickness of the tungsten layer is 1.5mm, the thickness of the molybdenum layer is 5.5mm, and the thickness of the graphite layer is 33mm (including the bonding layer thickness of 0.1mm) .

[0054] According to the formula m=ρπr 2 h, respectively calculate the mass of tungsten powder and molybdenum powder. Take 81.86 grams of tungsten powder with a purity of 99.7% and a particle size of 1 μm to 6 μm, calculate and take 0.41 ml of glycerol with analytical purity according to the mass volume ratio of tungsten powder at 5 ml / kg, and put the above raw materials into the mixer After mixing for 8 hours, sieve with a 50-mesh sieve to obtain tungsten powder. Take 158.93 grams of molybdenum powder with a purity of 99.7% and a particle size of 1 μm to 6 μm, calculate and take 0.80 ml of glycerol of analytical purity according to the mass-volume ratio of molybdenum powder 5ml...

Embodiment 3

[0056] Prepare a W / Mo / graphite composite anode target with a diameter of 100mm and a height of 60mm, in which the thickness of the tungsten layer is 2mm, the thickness of the molybdenum layer is 6mm, and the thickness of the graphite layer is 52mm (including a bonding layer thickness of 0.1mm).

[0057] According to the formula m=ρπr 2 h, respectively calculate the mass of tungsten powder and molybdenum powder. Take 303.17 grams of tungsten powder with a purity of 99.8% and a particle size of 1 μm to 6 μm, calculate and take 1.51 ml of glycerol of analytical purity according to the mass volume ratio of tungsten powder and 5 ml / kg, and put the above raw materials into the mixer Within 9 hours, after mixing evenly, sieve with a 55-mesh sieve to obtain tungsten powder. Take 481.61 grams of molybdenum powder with a purity of 99.8% and a particle size of 1 μm to 6 μm, calculate and take 2.4 ml of glycerol with analytical purity according to the mass-volume ratio of the molybdenum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com