Method for preparing hydrogen gas

A technology for the production of hydrogen, microorganisms, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

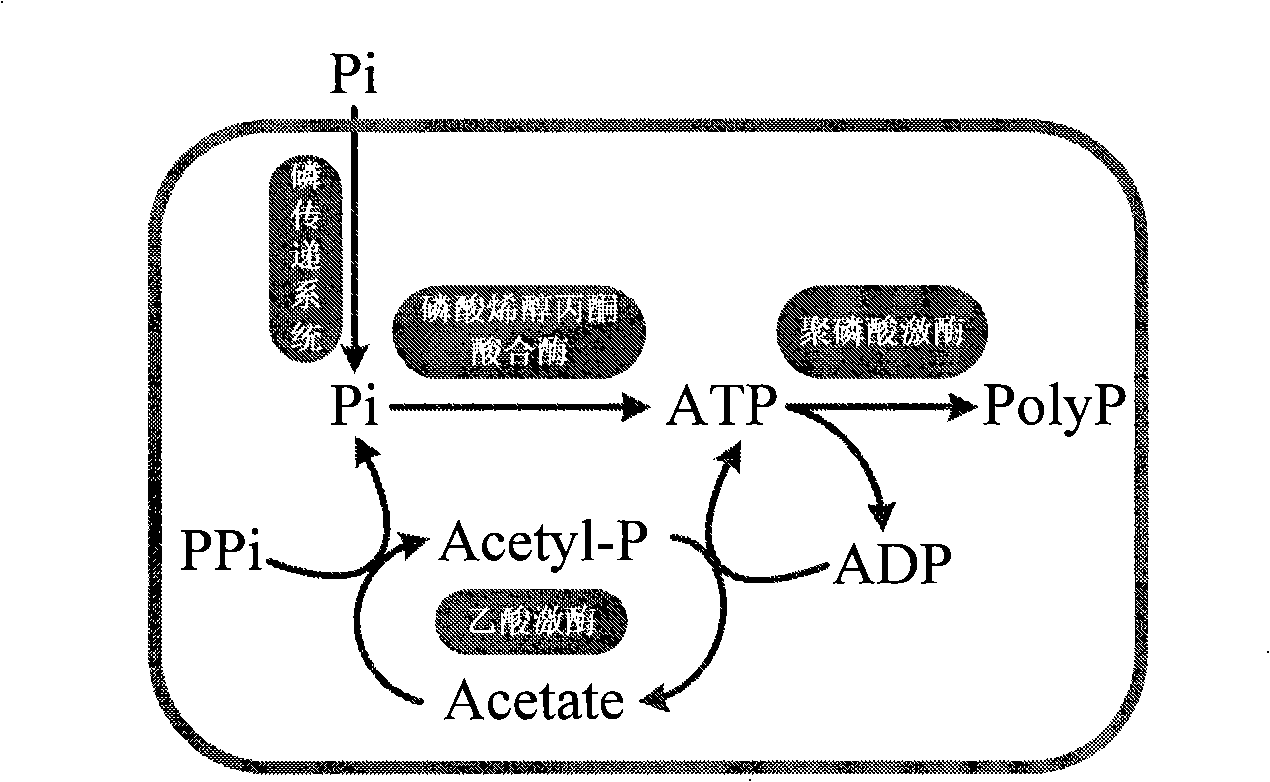

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, adopt basal culture medium to produce hydrogen

[0036] The pH of the basal medium (glucose 10.0 g / L, tryptone 5.0 g / L, ammonium sulfate 2.0 g / L, magnesium sulfate 0.2 g / L) was adjusted to 6.0. Enter the activated Enterobacter aerogenes (Enterobacter aerogenes IAM1183) in the culture medium, so that the initial content of Enterobacter aerogenes IAM1183 is 5×10 8 CFU / ml, cultured at 37°C, 170rpm for 15h. During the cultivation process, anaerobic conditions were adopted, and oxygen in the air was removed by nitrogen purging. During the cultivation process, the generated gas was collected. After the cultivation, the total amount of hydrogen gas generated was calculated, and the remaining content of glucose in the medium was detected at the same time.

[0037] The measurement of hydrogen adopts the method of gas chromatography (GC112A model gas chromatograph of Shanghai Precision Scientific Instrument Co., Ltd.; TCD detector; TDX-01 stainless steel packed co...

Embodiment 2

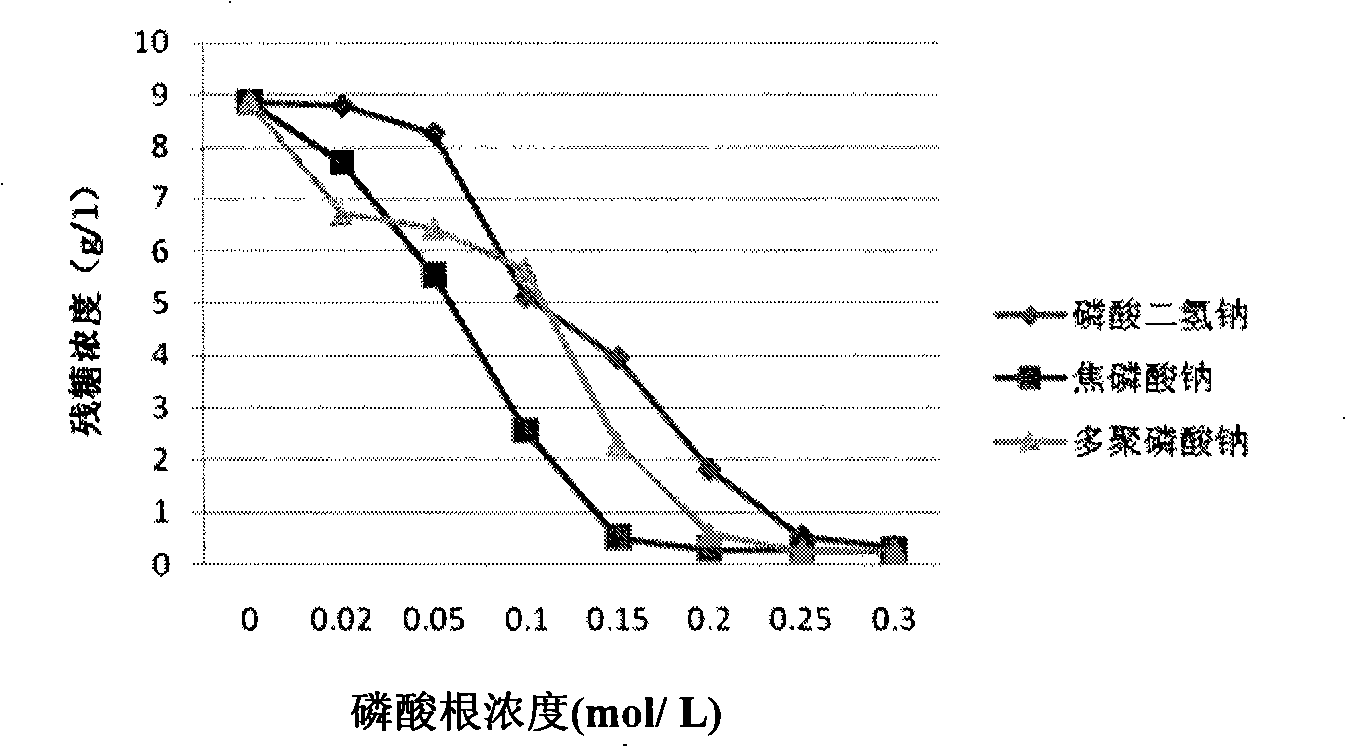

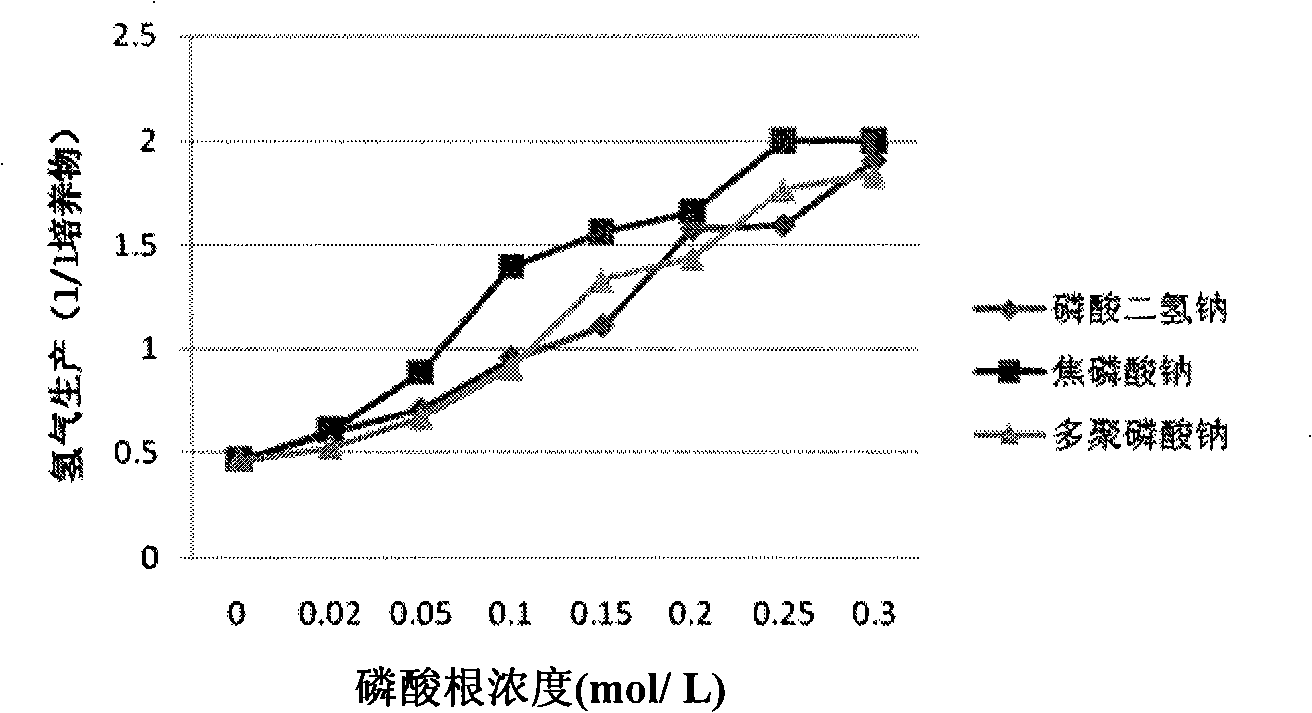

[0040] Embodiment 2, adopt the culture medium that adds inorganic phosphate to produce hydrogen

[0041] The pH of the basal medium (glucose 10.0 g / L, tryptone 5.0 g / L, ammonium sulfate 2.0 g / L, magnesium sulfate 0.2 g / L) was adjusted to 6.0. Add different amounts of sodium dihydrogen phosphate to the basal medium, so that the concentration of inorganic phosphate in each medium is 0, 0.02, 0.05, 0.1, 0.15, 0.2, 0.25, 0.3 mol / L. Each culture medium with different inorganic phosphate content was respectively inoculated with Enterobacter aerogenes IAM1183, so that the initial content of Enterobacter aerogenes IAM1183 was 5×10 8 CFU / ml, cultured at 37°C, 170rpm for 15h. During the cultivation process, anaerobic conditions were adopted, and oxygen in the air was removed by nitrogen purging. Collect the gas produced during the cultivation of each culture medium, calculate the total amount of hydrogen generated after the culture, and detect the glucose content in each culture mediu...

Embodiment 3

[0046] Embodiment 3, adopt the substratum that adds pyrophosphate to produce hydrogen

[0047] The pH of the basal medium (glucose 10.0 g / L, tryptone 5.0 g / L, ammonium sulfate 2.0 g / L, magnesium sulfate 0.2 g / L) was adjusted to 6.0. Add different amounts of sodium pyrophosphate to the basal medium to make the concentration of pyrophosphate in the medium respectively 0, 0.02, 0.05, 0.1, 0.15, 0.2, 0.25, 0.3 mol / L. Each medium with different content of pyrophosphate was inoculated with Enterobacter aerogenes IAM1183, so that the initial content of Enterobacter aerogenes IAM1183 was 5×10 8 CFU / ml, cultured at 37°C, 170rpm for 15h. During the cultivation process, anaerobic conditions were adopted, and oxygen in the air was removed by nitrogen purging. Collect the gas produced during the cultivation of each culture medium, calculate the total amount of hydrogen generated after the culture, and detect the glucose content in each culture medium at the same time.

[0048] The assay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com