Preparation of degradable gasification anti-rust film

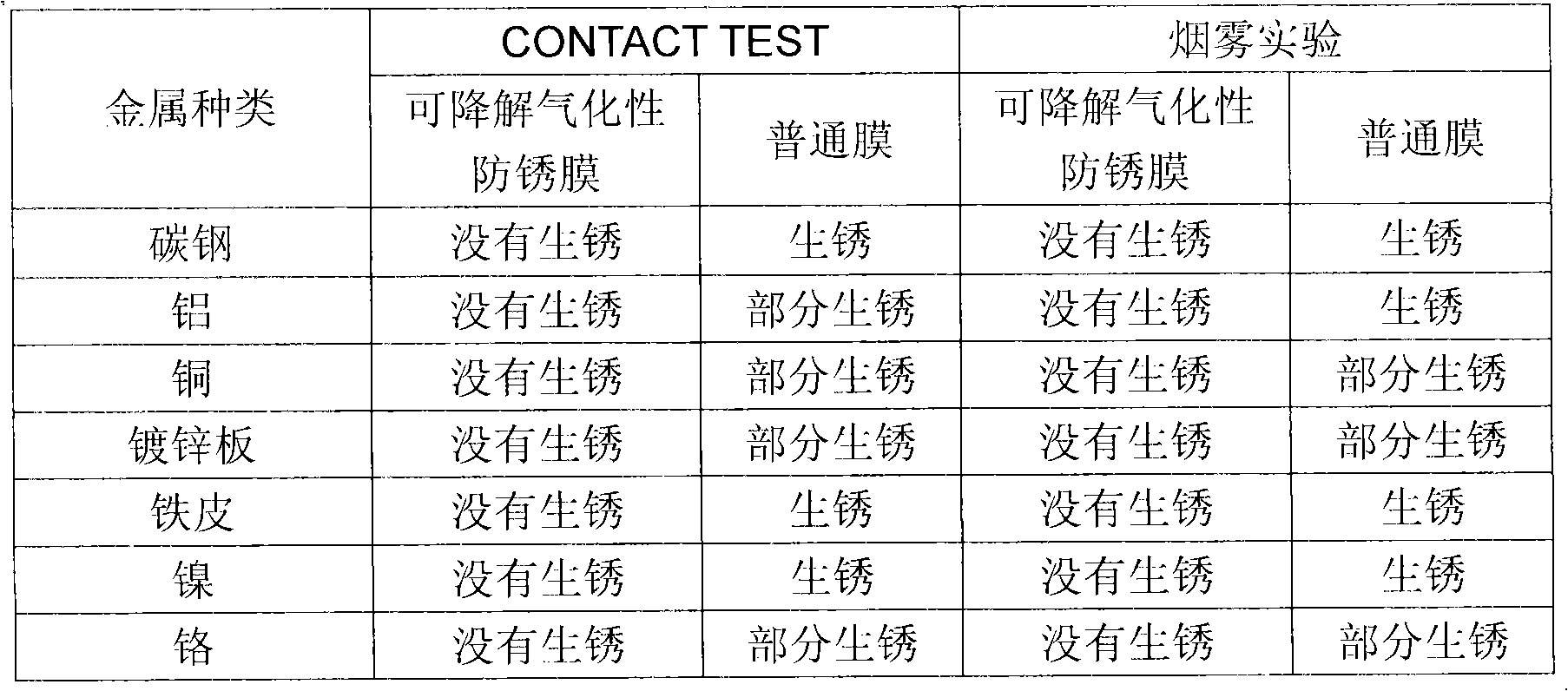

A technology of gasification antirust and raw materials, which is applied in the field of preparation of degradable gasification antirust film, can solve the problems of burning or burying in the ground, polluting the environment, etc., and achieves easy condition control, low preparation cost and high product quality good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] This embodiment includes raw material mixing, crushing, secondary raw material mixing, PE material mixing and film blowing process steps, and its raw material mixing refers to taking by weight 8 grams of sodium benzoate, 8 grams of dextrin, and 6 grams of benzotriazole. Put the weighed raw materials into a commercially available mixer, fully stir and mix for 20 minutes to obtain 23 grams of mixed raw materials evenly; the pulverization process is to pulverize the mixed raw materials obtained during the raw material mixing process using common pulverizing equipment Become 350 order fineness and make 23 gram particle mixed raw materials; Its secondary raw material is mixed and is to put into nano-copper powder 5 grams respectively by weight ratio in 23 gram particle mixed raw materials, polyethylene fat 7 grams, zinc stearate 3 gram; Then use the mixer of 25rpm speed to fully stir and mix for 30 minutes to evenly obtain 38 grams of secondary mixed raw materials; the PE mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com