Method for acidylation modification of hemicellulose and modified hemicellulose

A technology of hemicellulose and acylation, which is applied in the field of hemicellulose acylation modification and acylation modification of hemicellulose, which can solve the problems of increased use of chemical reagents, long chemical reaction time, and long heating time. Achieve the effects of saving heating time, avoiding white pollution, and using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

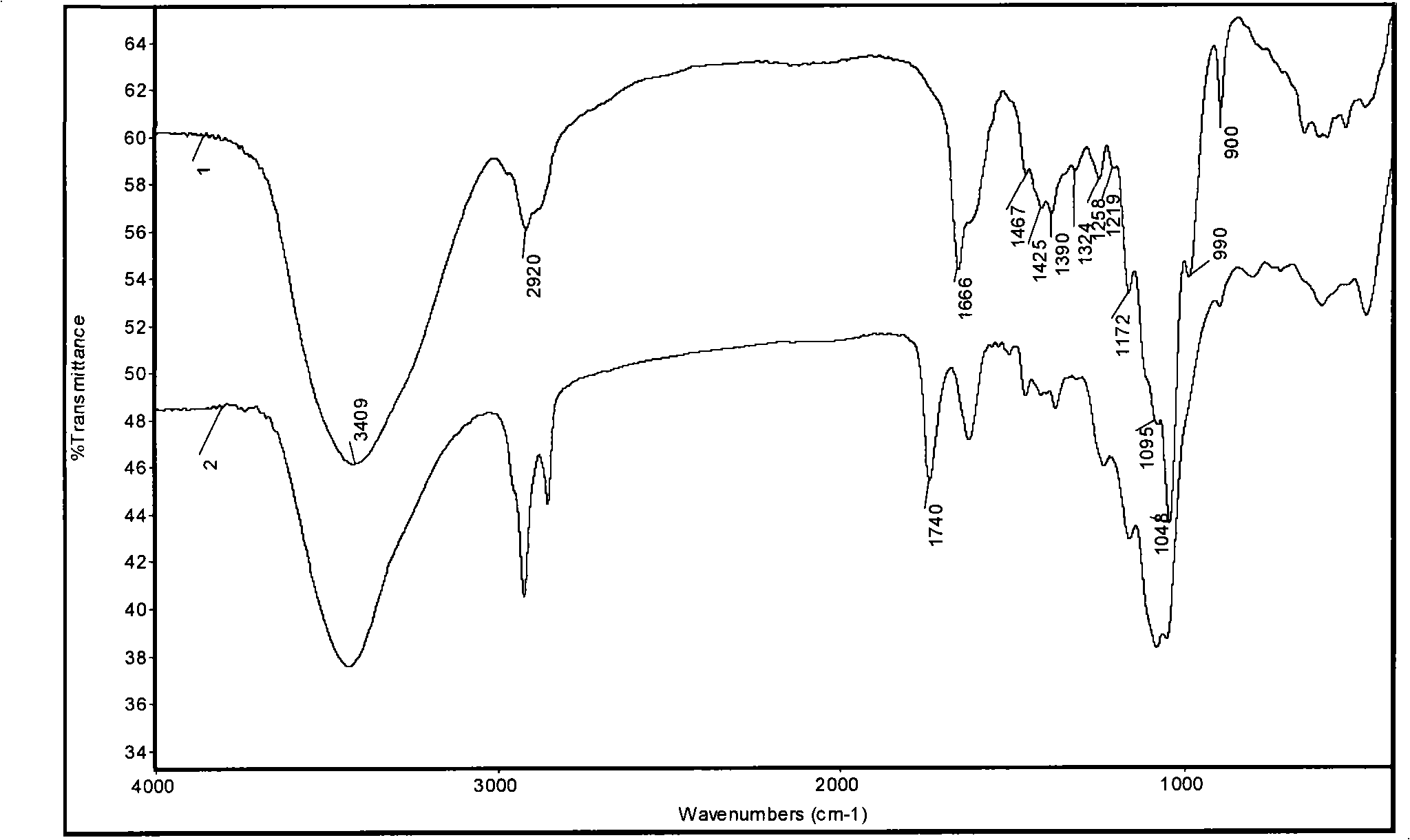

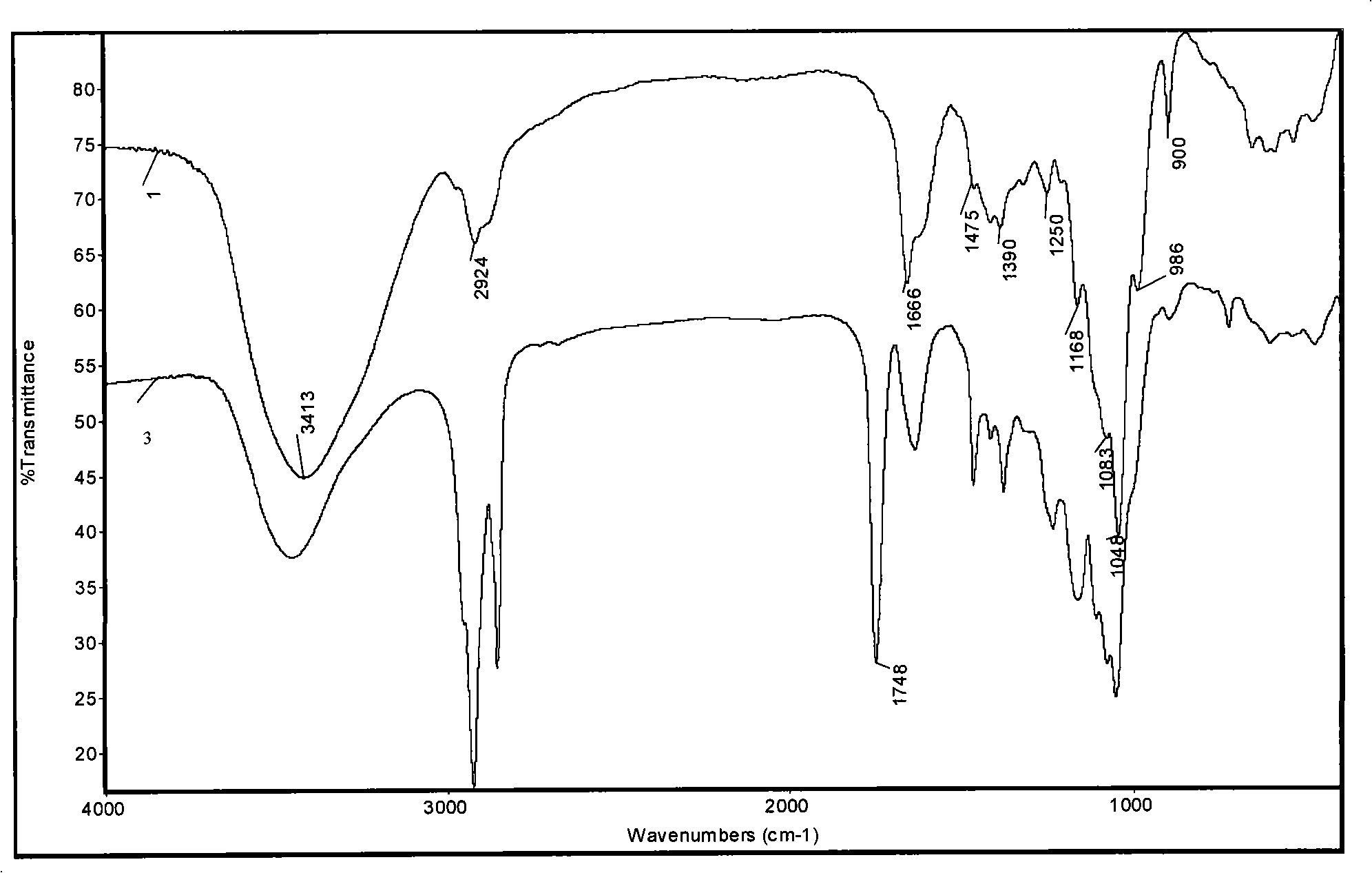

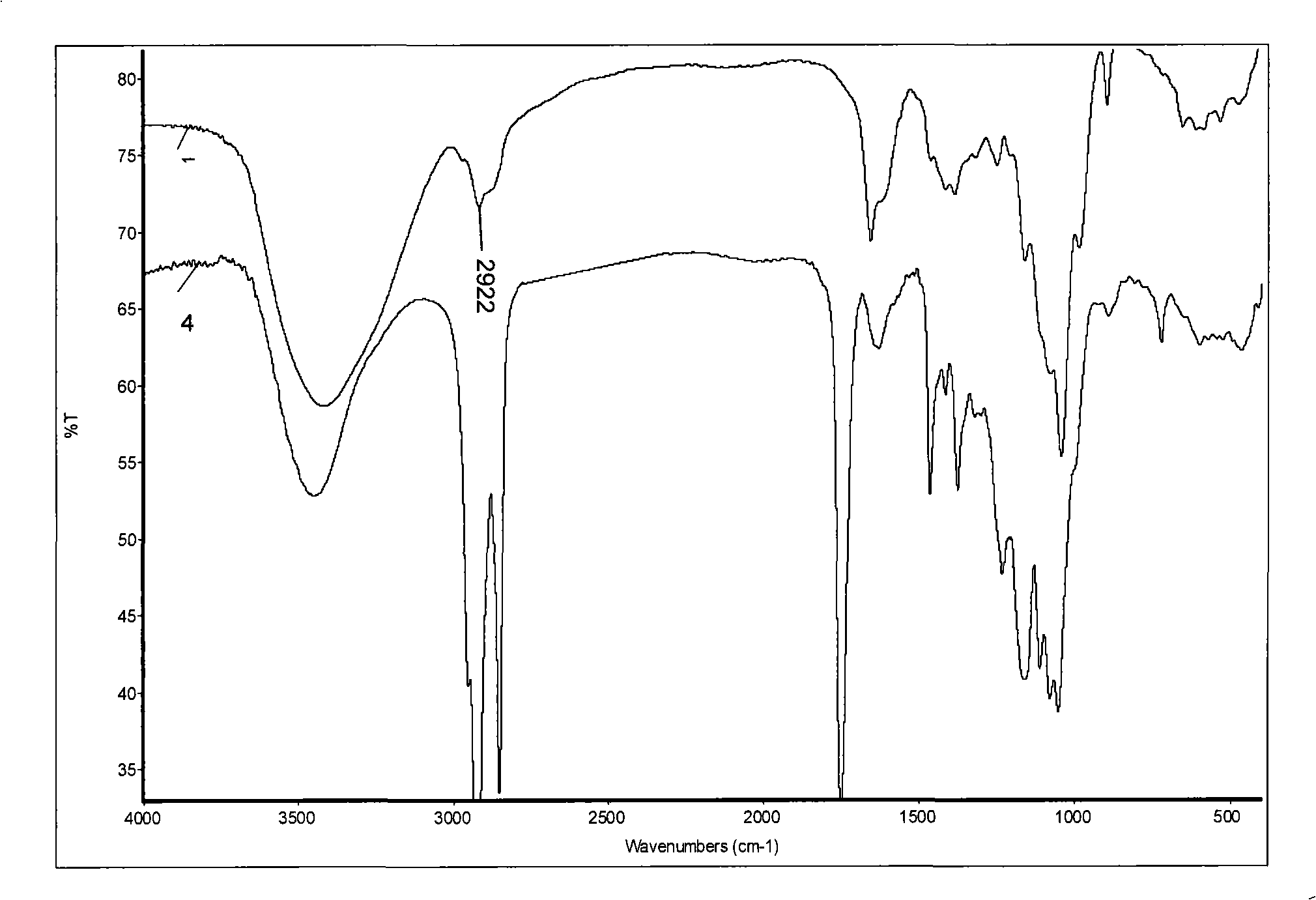

Image

Examples

preparation example Construction

[0031] Preparation of straw hemicellulose.

[0032] The stalk that 50g pulverizes is placed in the glass reactor of 3000ml, adding mass percent concentration is 2% H 2 o 2 Aqueous solution, adjust pH value to 11.5 with NaOH (mass percent concentration is 20%) solution, control reaction temperature to be 50 ℃, react under stirring for 17 hours; then filter, and wash filter residue with distilled water, combine filtrate; Add 6M HCl solution to adjust the pH to 6.0; then add 3.5 times the volume of 95% ethanol to the solution to precipitate the soluble hemicellulose, filter the precipitated hemicellulose, and fully wash with 70% acidic ethanol (pH6.0) solution The filter residue is obtained by drying the filter residue in the air and crushing the dried hemicellulose.

[0033] Using the prepared 0.66g hemicellulose (containing 0.01mol xylose hydroxyl group) as raw material, the acylation reaction was carried out.

Embodiment 1

[0035] 1. Prepare materials according to the following ratio:

[0036] Straw hemicellulose powder (containing 0.01mol xylose hydroxyl) 0.66g

[0037] N,N-Dimethylformamide (DMF) 35ml

[0038] Lithium chloride (LiCl) 0.10g

[0039]N-Bromosuccinimide (NBS) 0.033g

[0040] Propanoyl chloride 0.93g

[0041] 2. Preactivation treatment of hemicellulose

[0042] First, put all the straw hemicellulose powder (0.01 mol of xylose hydroxyl group in hemicellulose composition) into a 100ml reactor, then add 10ml of distilled water, heat to 78°C, and keep stirring until the hemicellulose is completely dissolved.

[0043] Then, add 20ml of N,N-dimethylformamide (DMF), stir evenly, and repeatedly distill under reduced pressure at 50°C and a vacuum of 0.08Mpa to remove the distilled water in the swollen mixture to make the semi-fiber The mixture of element, distilled water and DMF is jelly, and distilled water accounts for 9% of mixture gross weight.

[0044] 3. Acylation reaction of hem...

Embodiment 2

[0052] 1. Prepare materials according to the following ratio:

[0053] Straw hemicellulose (containing 0.01mol xylose hydroxyl) 0.66g

[0054] N,N-Dimethylformamide (DMF) 35ml

[0055] Lithium chloride (LiCl) 0.10g

[0056] 4-Dimethylaminopyridine (DMAP) 0.033g

[0057] n-octyl chloride 3.3g

[0058] 2. Preactivation treatment of hemicellulose

[0059] First: put all the straw hemicellulose powder (0.01mol xylose hydroxyl group in the hemicellulose composition) in a 100ml reactor, then dissolve it in 10ml distilled water, heat to 78°C, and keep stirring until the hemicellulose is completely dissolve.

[0060] Then, add 20ml of N,N-dimethylformamide (DMF), stir evenly, and repeatedly distill under reduced pressure at 50°C and a vacuum of 0.08Mpa to remove the distilled water in the swelling mixture, and make the hemicellulose, The mixture of distilled water and DMF was jelly, and distilled water accounted for 9% of the total amount of the mixture.

[0061] 3. Acylation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com