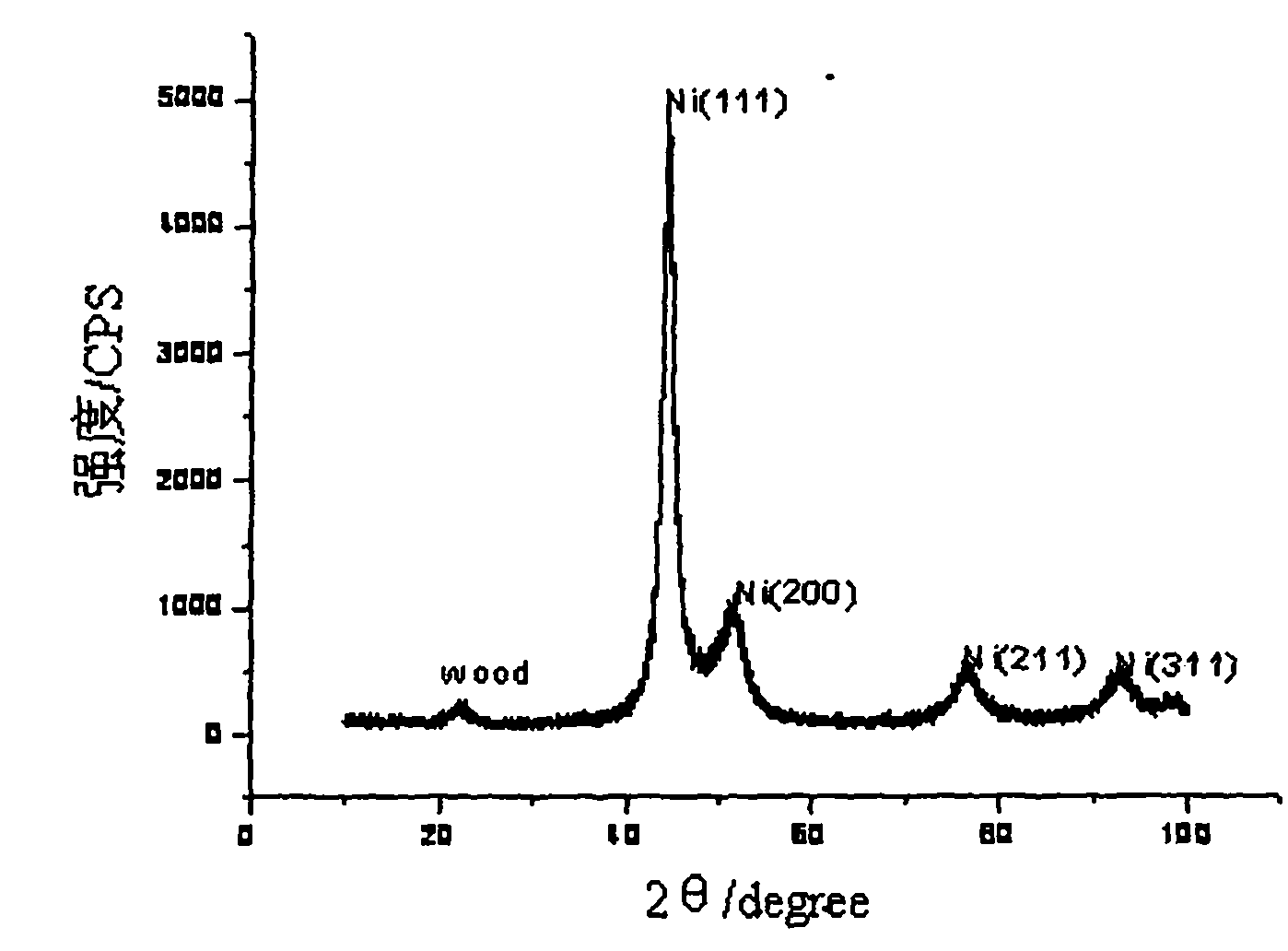

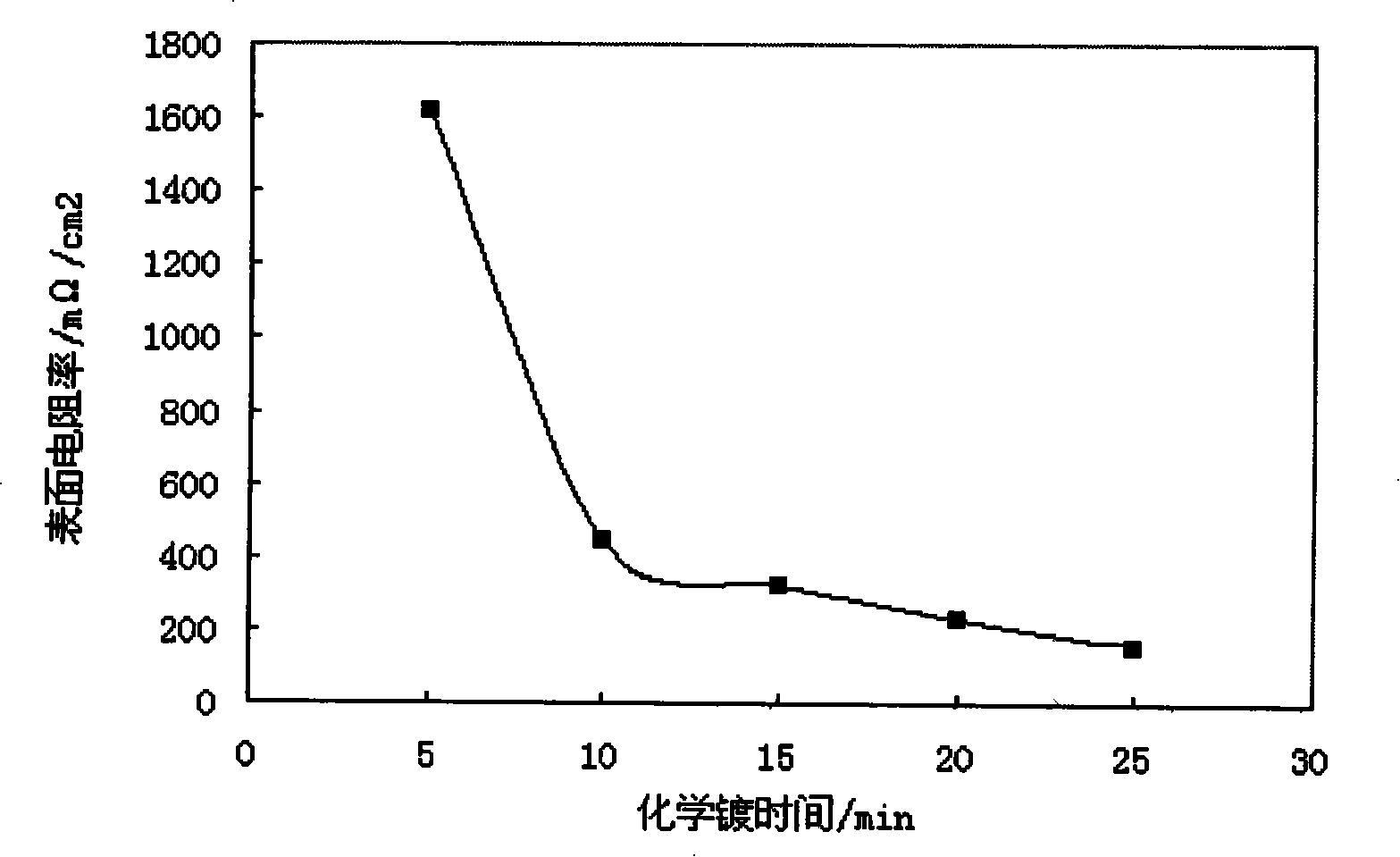

Chemical nickel plating process on surface of wood

A technology for electroless nickel plating and wood surface, applied in the field of chemical plating on wood surface, can solve the problems of environmental pollution coating and non-metal bonding strength, complex process, complex composition of activation solution, etc., achieves good electromagnetic shielding effect, does not pollute the environment, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the method for chemical nickel plating on the wood surface of the present embodiment is realized according to the following steps: one, NaBH 4 Solution and NaOH solution are mixed to obtain reducing agent, and NaBH in reducing agent 4 The concentration of NaOH is 2-10g / L, and the concentration of NaOH is 0.5-5g / L; 2. Mix nickel sulfate, sodium hypophosphite, sodium acetate, lactic acid, ammonium chloride and thiourea solution to obtain a plating solution, and the pH of the plating solution is The value is 7~9, the concentration of nickel sulfate in the plating solution is 20~50g / L, the concentration of sodium hypophosphite is 20~50g / L, the concentration of sodium acetate is 10~30g / L, and the concentration of lactic acid is 10~50g / L. 25mL / L, the concentration of ammonium chloride is 10-30g / L, and the concentration of thiourea is 0.001-0.006g / L; 3. Immerse the wood in the reducing agent for 2-10min, take it out and place it at room temperature for...

specific Embodiment approach 2

[0009] Specific embodiment two: the difference between this embodiment and specific embodiment one is that NaBH in step one reducing agent 4 The concentration of NaOH is 5g / L, and the concentration of NaOH is 2g / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0010] Specific embodiment three: what this embodiment is different from specific embodiment one is that the concentration of nickel sulfate in the step two plating solution is 35g / L, the concentration of sodium hypophosphite is 35g / L, the concentration of sodium acetate is 20g / L, The concentration of lactic acid was 18mL / L, the concentration of ammonium chloride was 23g / L, and the concentration of thiourea was 0.003g / L. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com