Method for preparing room-temperature ferromagnetic Fe doped ZnO nanometer wire

A room temperature ferromagnetic and nanowire technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., to achieve the effects of low energy consumption, convenient operation and simple process

Inactive Publication Date: 2008-11-26

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

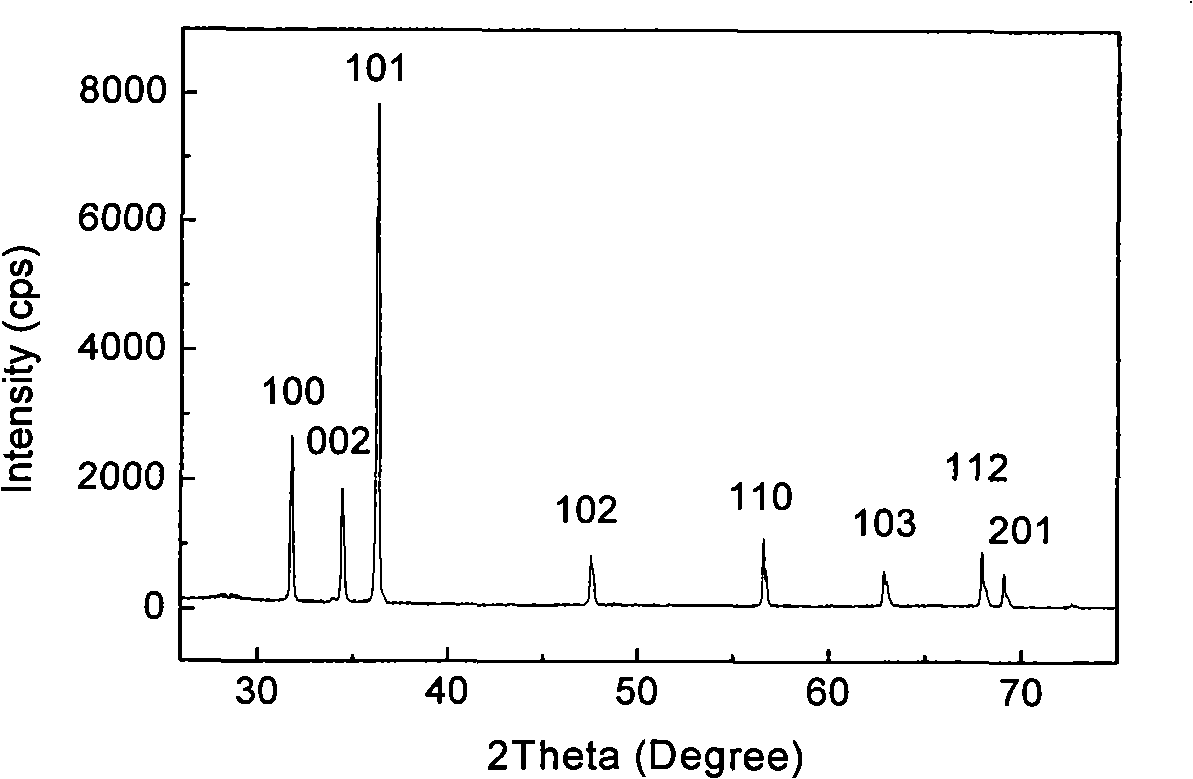

The present invention adopts the method of vapor phase deposition to carry out in-situ doping in the ZnO nanowire preparation process to solve the problem of reasonably doping the magnetic element Fe in the ZnO nanowire, and forms a solid solution by replacing the position of Zn after Fe doping

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

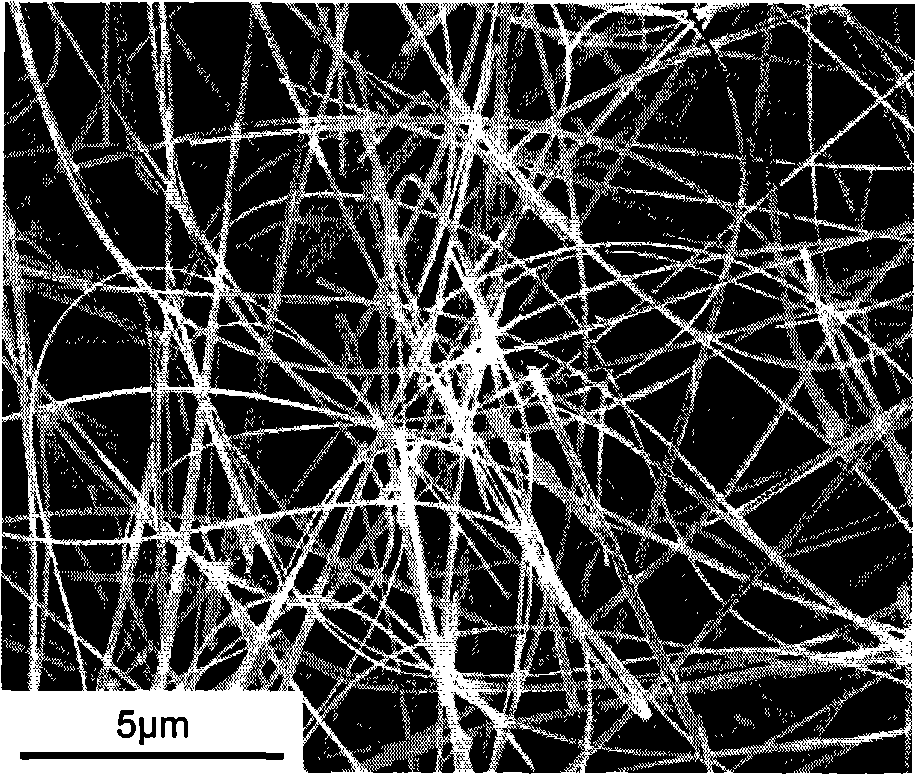

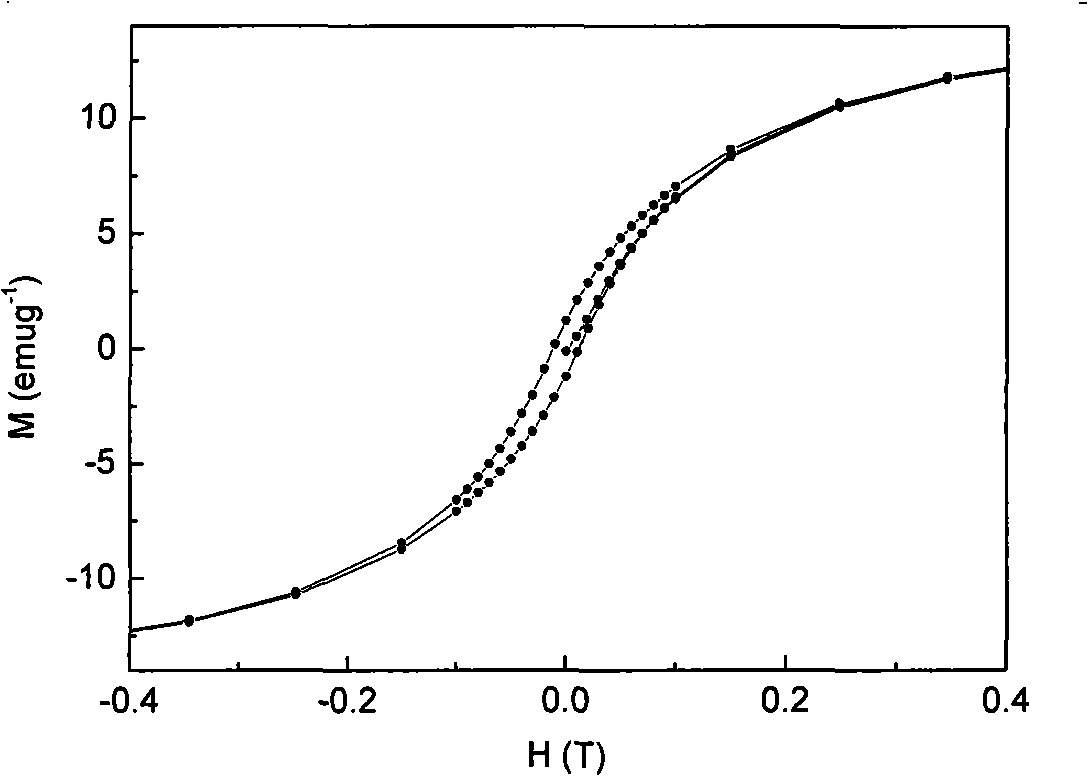

The invention discloses a method for preparing a ZnO nanowire with an adulteration of ferromagnetic Fe under a room temperature, which belongs to the field of semiconductor nanometer material preparation technology; a method of vapor deposition is adopted by the invention to carry out an original position adulteration in the process of preparing the ZnO nanowire; ZnO, C, and Fe powder are provided as evaporation sources, silicon chip is provided as a receiving lining which is placed on a corundum boat and positioned right above the evaporation and has a vertical distance of 2-4mm with the evaporation source. Then, all materials are put in a pipe typed stove where 300-350 ml / min argon is inlet; after 5-8 min, flow rate of the argon is changed to 120-160ml / min; the pipe typed stove is heated to a temperature of 950-1050 DEG C, with an internal pressure of the stove maintained at 0.03-0.05Mpa; heat preservation for 140-160 min, the stove is naturally cooled to the room temperature, thus obtaining the large scale of well distributed ZnO nanowire with the adulteration of Fe. The method solves the problem of reasonably adulterating magnetic element Fe to the ZnO nanowire; the obtained ZnO nanowire with the adulteration of ferromagnetic Fe has ferromagnetism under a room temperature. The method has the advantages that the raw materials are cheap; the technique is simple; the energy consumption is low; the productivity is high; the product is pollution free to the environment and is applicable to an industrialized production.

Description

A method for preparing ferromagnetic Fe-doped ZnO nanowires at room temperature technical field The invention belongs to the technical field of semiconductor nanomaterial preparation, and relates to a preparation technology for growing Fe-doped ZnO nanowires by chemical vapor deposition. Background technique As a source of spin carriers, the preparation of magnetic semiconductor materials has always been the most critical link in semiconductor spintronics. Whether it can maintain room temperature ferromagnetism is the key factor that determines whether it is practical. Transition group element Fe-doped ZnO is considered to be one of the most promising semiconductors with high Curie temperature, which has aroused great research interest. In addition, the magnetic semiconductor based on ZnO has wide band gap, large exciton binding energy, and obvious magneto-optical effect, so it also has broad application prospects in magneto-optical devices. With the rapid development of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C30B29/16C30B29/62C30B25/00

Inventor 常永勤

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com