Method for fermentation preparation of Ectoine

A technology of microbial fermentation and concentration, applied in the field of microbial fermentation, can solve the problems of high price of transcription inducer, low synthesis amount, and no obvious improvement of Ectoine fermentation yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Strain: H. salina DSM 5928;

[0034] Medium: L-monosodium glutamate 30g / L, KH 2 PO 4 3g / L, K 2 HPO 4 9g / L, MgSO 4 ·7H 2 O0.4g / L, MnSO 4 4H 2 O 0.01g / L, NaCl 60g / L, pH7.2, 0.2μm filter sterilization;

[0035] Cultivation method: After the bacterial strain was cultured in a test tube containing 5 mL of the above-mentioned medium at 30°C and on a shaker (120rpm) for 24 hours, it was transferred to 30mL of the above-mentioned medium (300mL Erlenmeyer flask) by 1% (volume) inoculation amount ), cultured at 30°C with a shaker at 120rpm, and sampled for 36 hours to measure the concentration of Ectoine inside and outside the cells;

[0036] Results: According to molecular weight and structure identification and analysis, there was secreted Ectoine in the culture medium; the concentration of Ectoine in cells was 0.56g / L, the concentration of Ectoine in culture medium was 0.68g / L, and the secretion rate was 55%.

Embodiment 2

[0038] Bacterial strains: Halomonas (Halomonas) and several other microorganisms, see Table 1;

[0039] Culture medium condition and culture method are as embodiment 1; Experimental result is shown in table 1:

[0040] Table 1

[0041]

[0042] (to be continued)

[0043] (Continued from Table 1)

[0044]

[0045] It can be seen from the results in Table 1 that under the same culture conditions, not all Ectoine synthetic strains can secrete Ectoine.

Embodiment 3

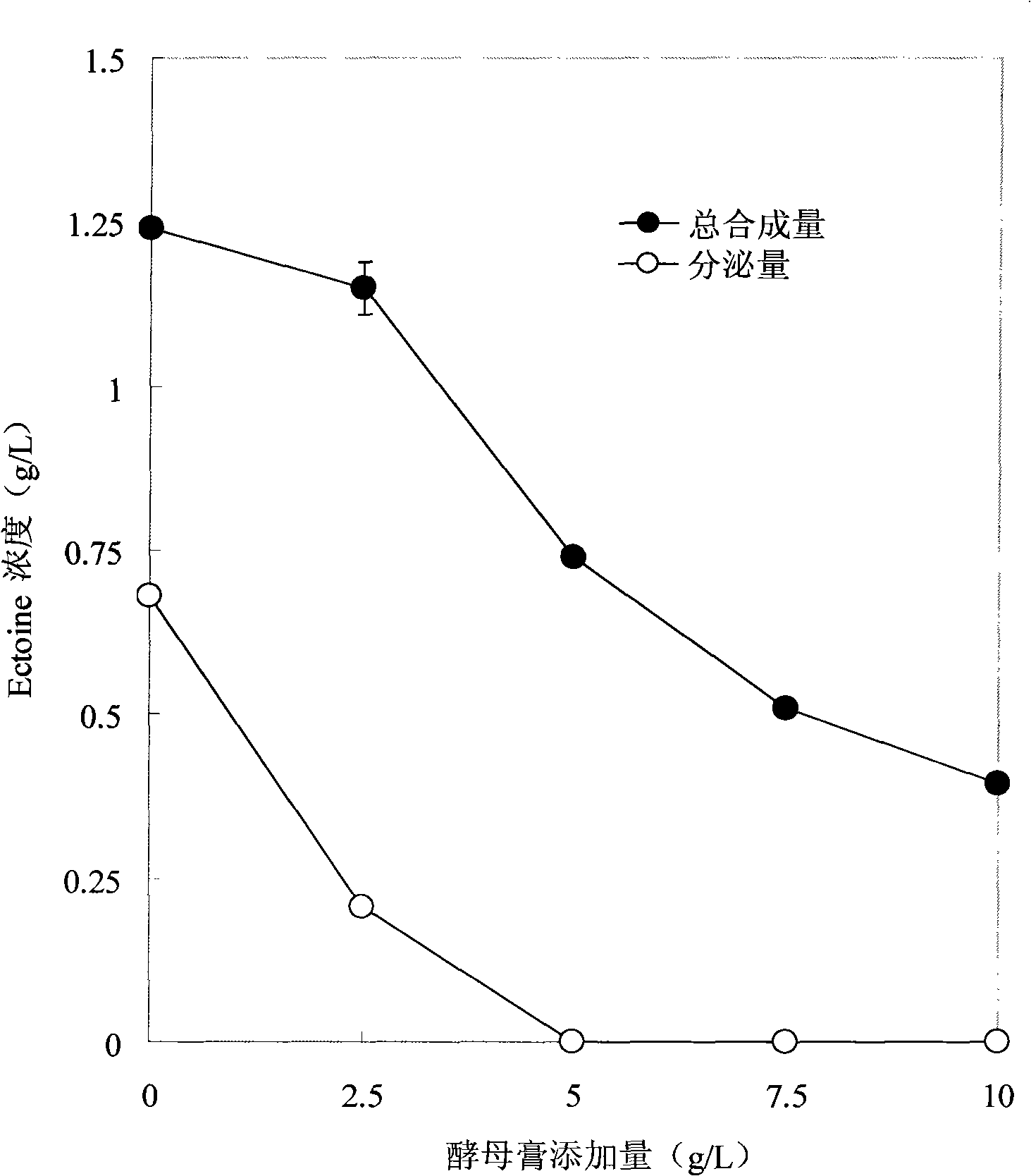

[0047] This example examines the effect of adding yeast extract on the synthesis and secretion of Ectoine by H. salina DSM 5928.

[0048] In this embodiment, on the basis of Example 1, 0 to 10 g / L of yeast extract is added to the medium, and Ectoine is induced and synthesized according to the culture conditions of Example 1, and the total amount of Ectoine synthesized (intracellular Ectoine amount and secretion The sum of Ectoine amount) and secretion amount, the results are shown in the appendix figure 1 shown.

[0049] It can be seen that the total synthesis and secretion of Ectoine decreased with the increase of yeast extract concentration, especially when the yeast extract concentration reached 10g / L, H.salina DSM 5928 only secreted a small amount of Ectoine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com