Composite semipermeable membrane, process for production of the same, and use thereof

一种复合半透膜、支持膜的技术,应用在半透膜分离、化学仪器和方法、膜技术等方向,能够解决硼阻止率提高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

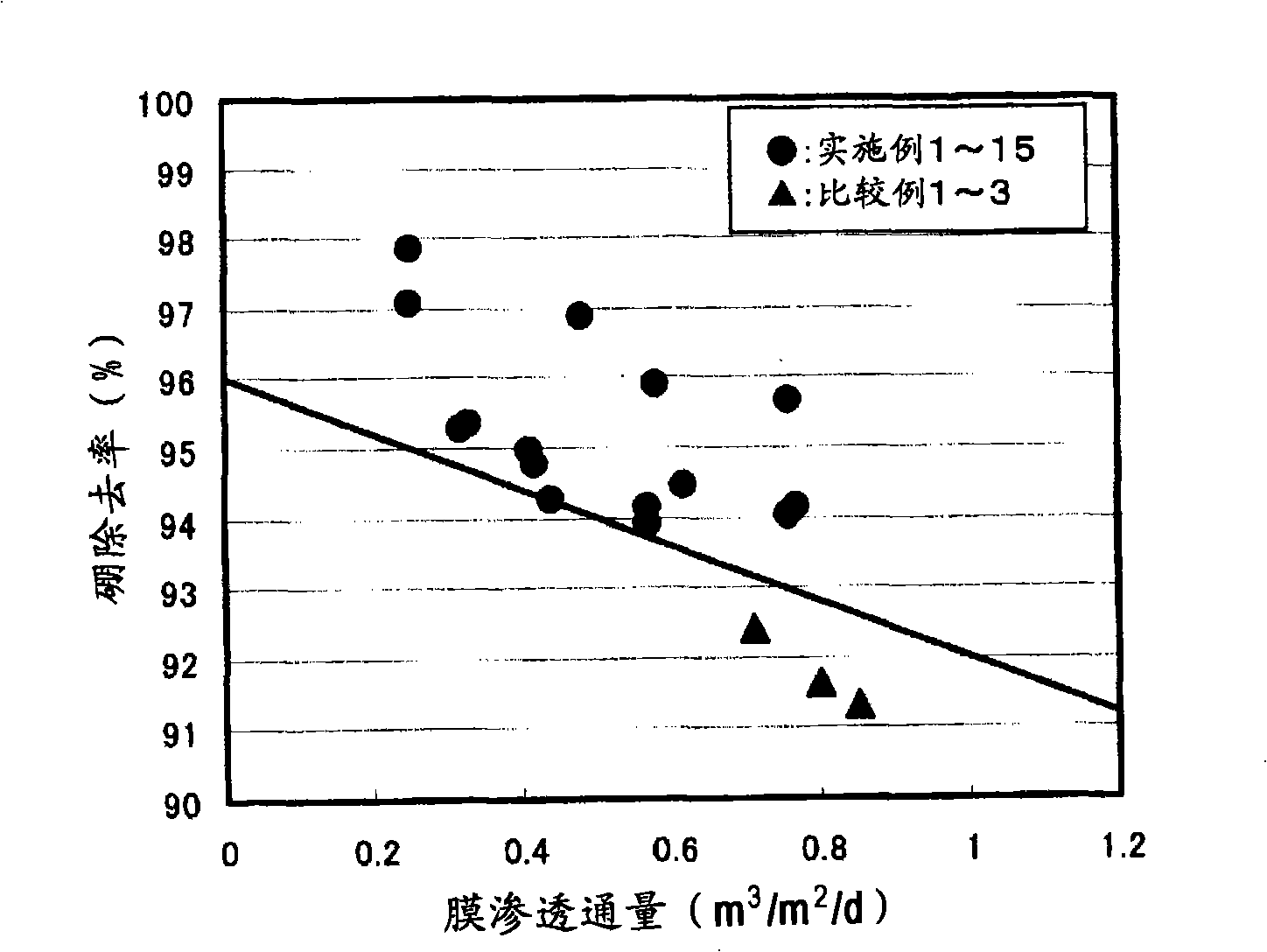

[0080] The characteristics of the composite semipermeable membranes of Examples and Comparative Examples were obtained as follows: Under an operating pressure of 5.5 MPa, the composite semipermeable membrane was supplied with seawater adjusted to a temperature of 25° C. and a pH of 6.5 (TDS concentration about 3.5%, boron concentration About 5.0ppm), perform membrane filtration treatment, measure the water quality of the permeated water obtained and the water quality of the supplied water, and obtain it from this. The measured values or calculation formulas are as follows.

[0081] (TDS removal rate)

[0082] The TDS concentration in the permeate water and the TDS concentration in the feed water were measured, and the TDS removal rate (%) was calculated according to the following formula.

[0083] TDS removal rate (%)=100×{1-(TDS concentration in permeate water / TDS concentration in feed water)}

[0084] (membrane permeation flux)

[0085] The membrane permeation water of ...

reference example 1

[0099] (Reference Example 1) Synthesis of (4-chlorocarbonylmethoxyphenoxy)acetyl chloride (compound 1)

[0100] Dissolve 5.51g (50.0mmol) of hydroquinone and 16.1g (105.0mmol) of methyl bromoacetate in 50.0ml of N,N-dimethylformamide (hereinafter referred to as DMF), and add 20.7g (150.0mmol) of potassium carbonate , stirred for 12 hours. Water was added to the reaction mixture, and after extraction with ethyl acetate, the organic layers were combined, washed with aqueous sodium bicarbonate solution, water, and saturated brine, and dried over anhydrous sodium sulfate. The desiccant was removed, the residue was concentrated under reduced pressure, and the resulting residue was recrystallized from dichloromethane / n-hexane to obtain 10.7 g of colorless crystals.

[0101] 7.80 g of this crystal was dissolved in 30.0 ml of methanol, 46.0 ml (92.0 mmol) of 2N aqueous sodium hydroxide solution was added over 20 minutes, and the mixture was stirred at room temperature for 12 hours. ...

reference example 2

[0104] Compound 2 was synthesized in the same manner as in Reference Example 1, except that hydroquinone was replaced with resorcinol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com